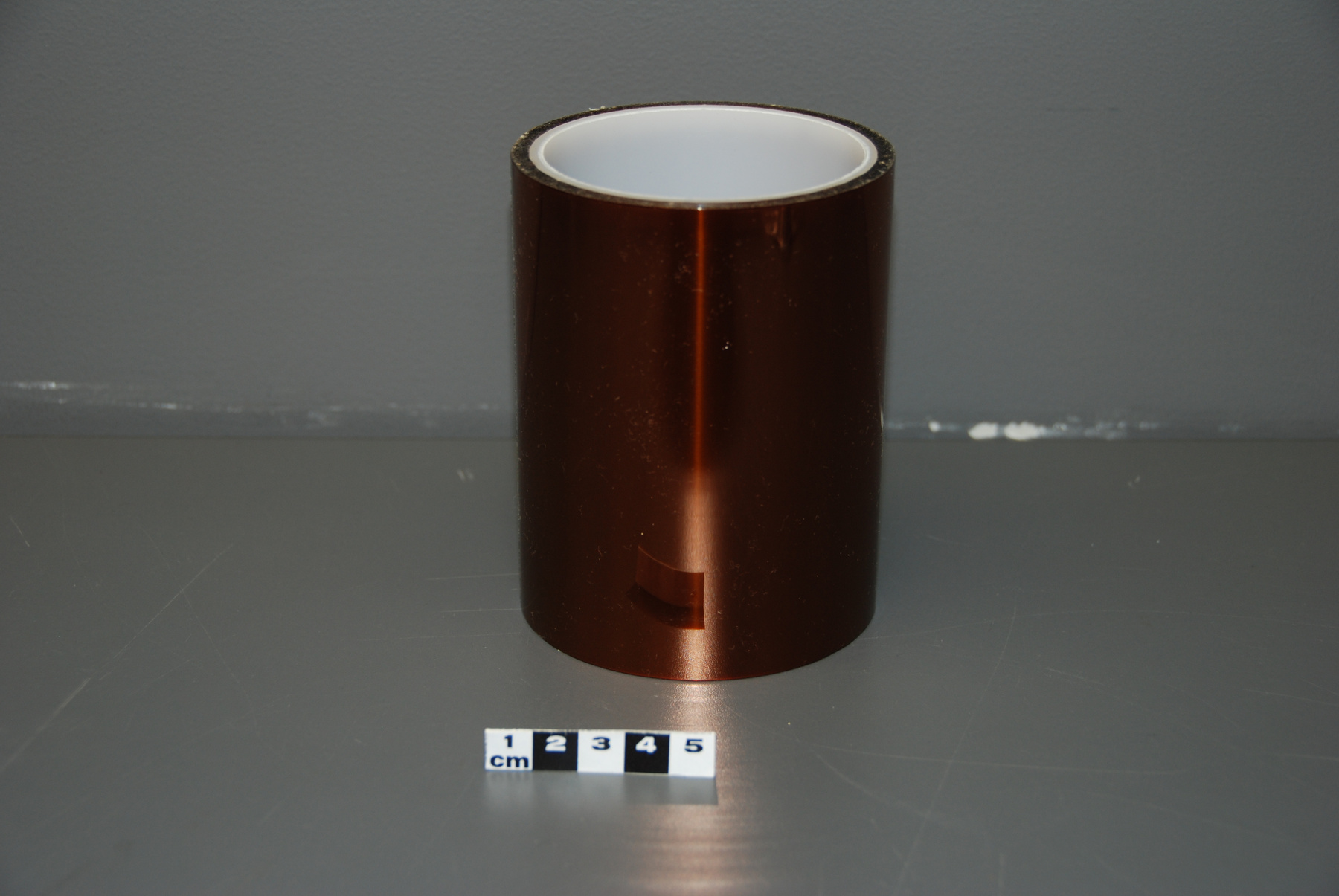

Tape, adhesive

Use this image

Can I reuse this image without permission? Yes

Object images on the Ingenium Collection’s portal have the following Creative Commons license:

Copyright Ingenium / CC BY-NC-ND (Attribution-NonCommercial 4.0 International (CC BY-NC 4.0)

ATTRIBUTE THIS IMAGE

Ingenium,

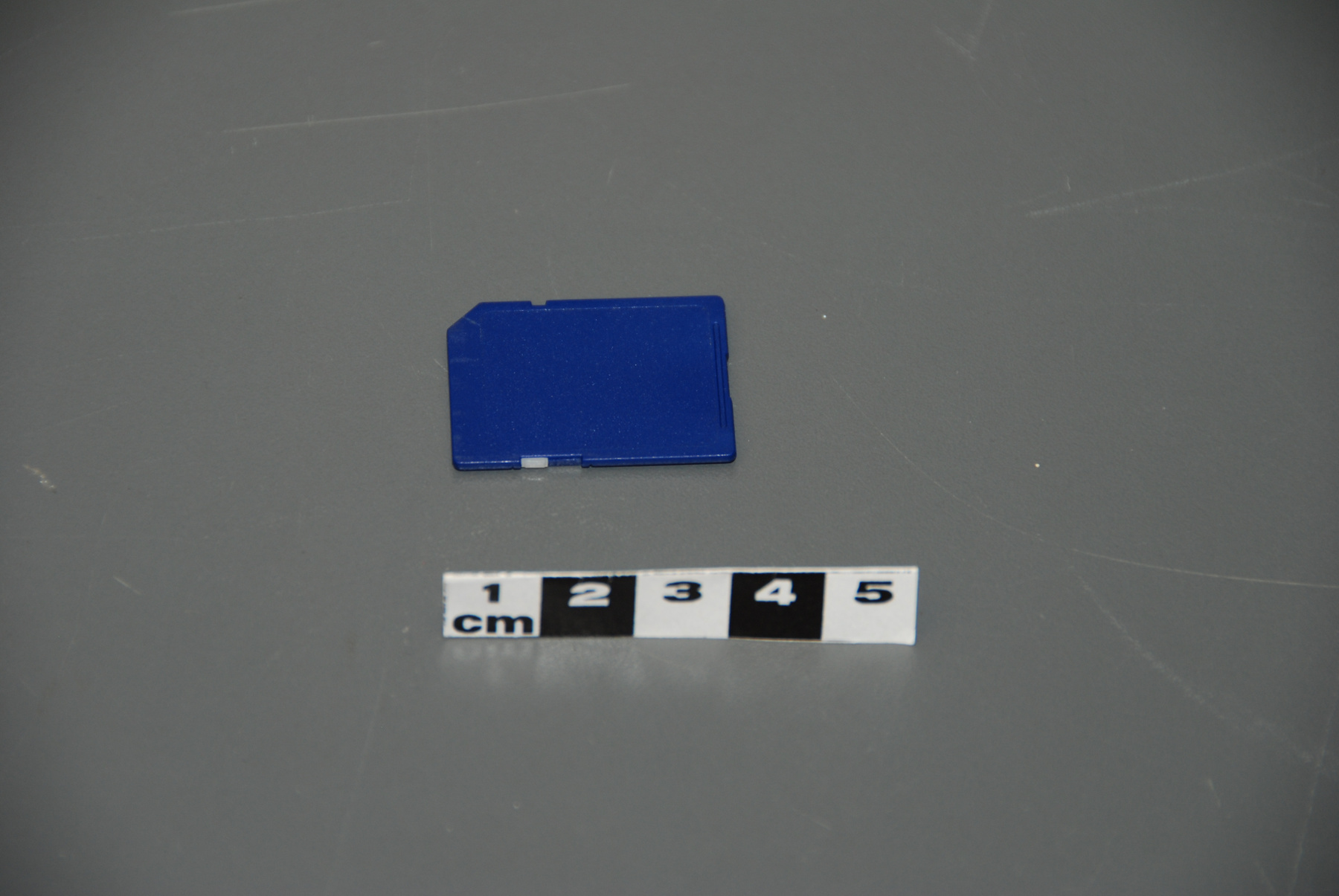

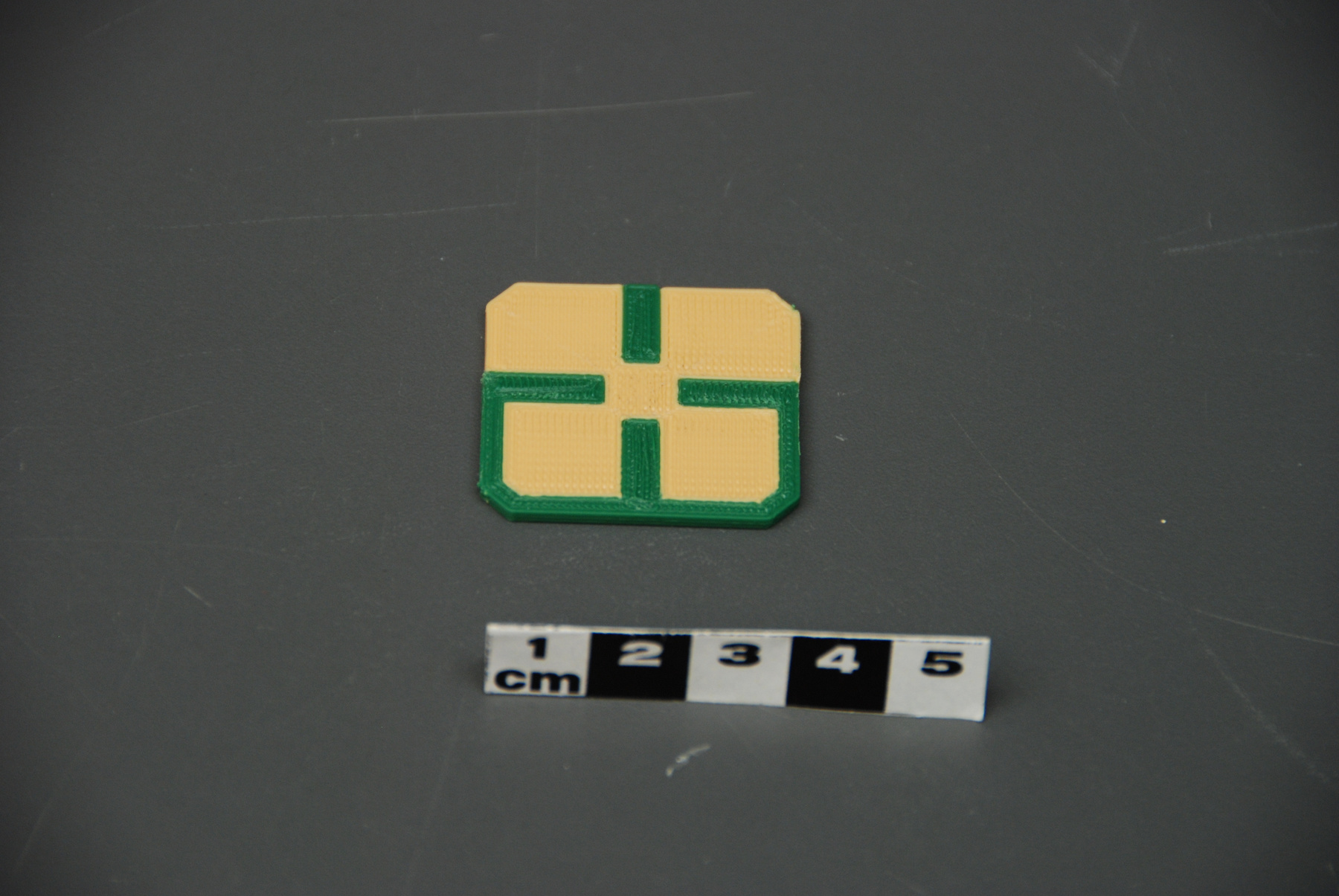

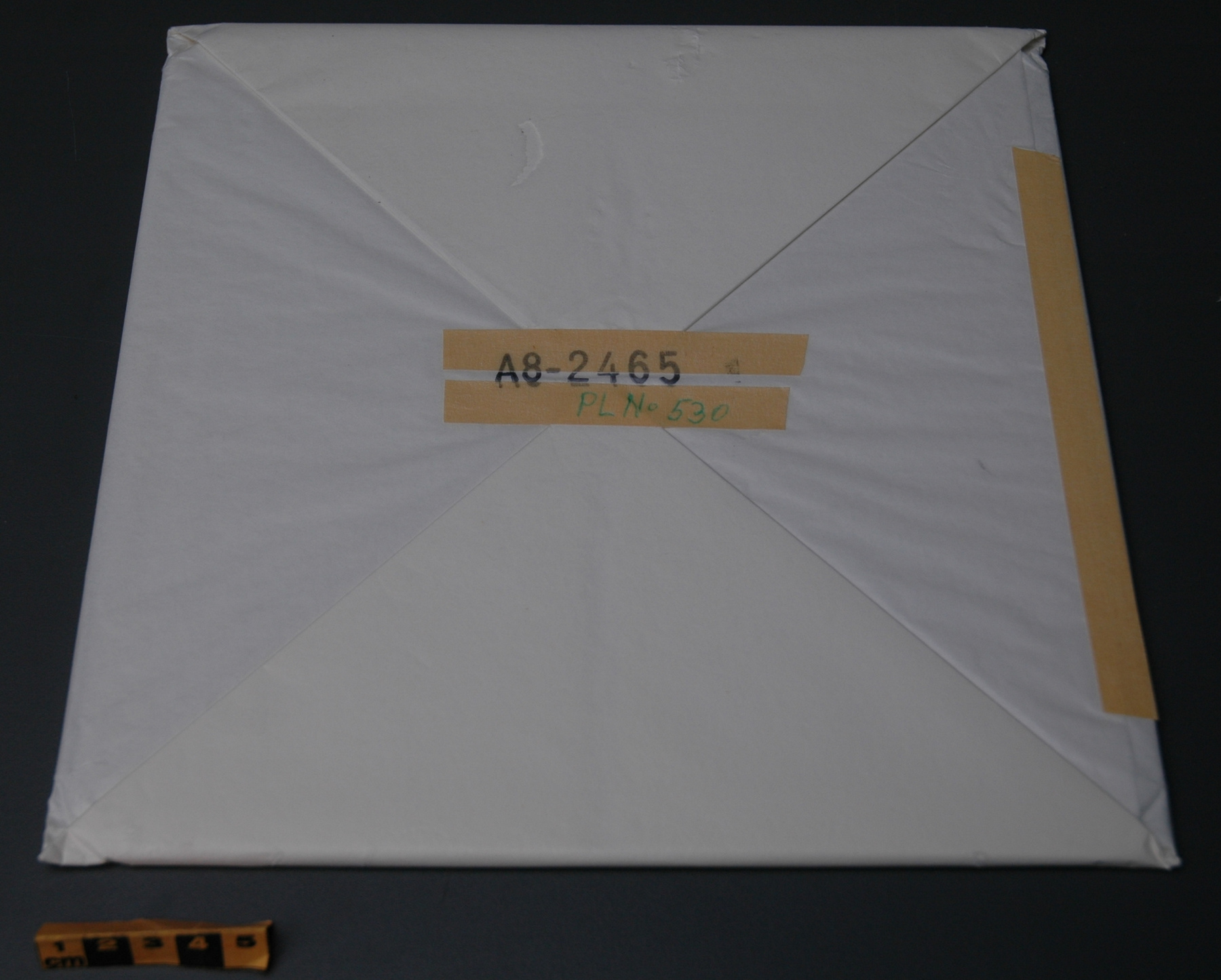

2013.0097.011

Permalink:

Ingenium is releasing this image under the Creative Commons licensing framework, and encourages downloading and reuse for non-commercial purposes. Please acknowledge Ingenium and cite the artifact number.

DOWNLOAD IMAGEPURCHASE THIS IMAGE

This image is free for non-commercial use.

For commercial use, please consult our Reproduction Fees and contact us to purchase the image.

- OBJECT TYPE

- Silicone

- DATE

- 2012

- ARTIFACT NUMBER

- 2013.0097.011

- MANUFACTURER

- Unknown

- MODEL

- Kapton

- LOCATION

- Unknown

More Information

General Information

- Serial #

- N/A

- Part Number

- 11

- Total Parts

- 22

- AKA

- N/A

- Patents

- N/A

- General Description

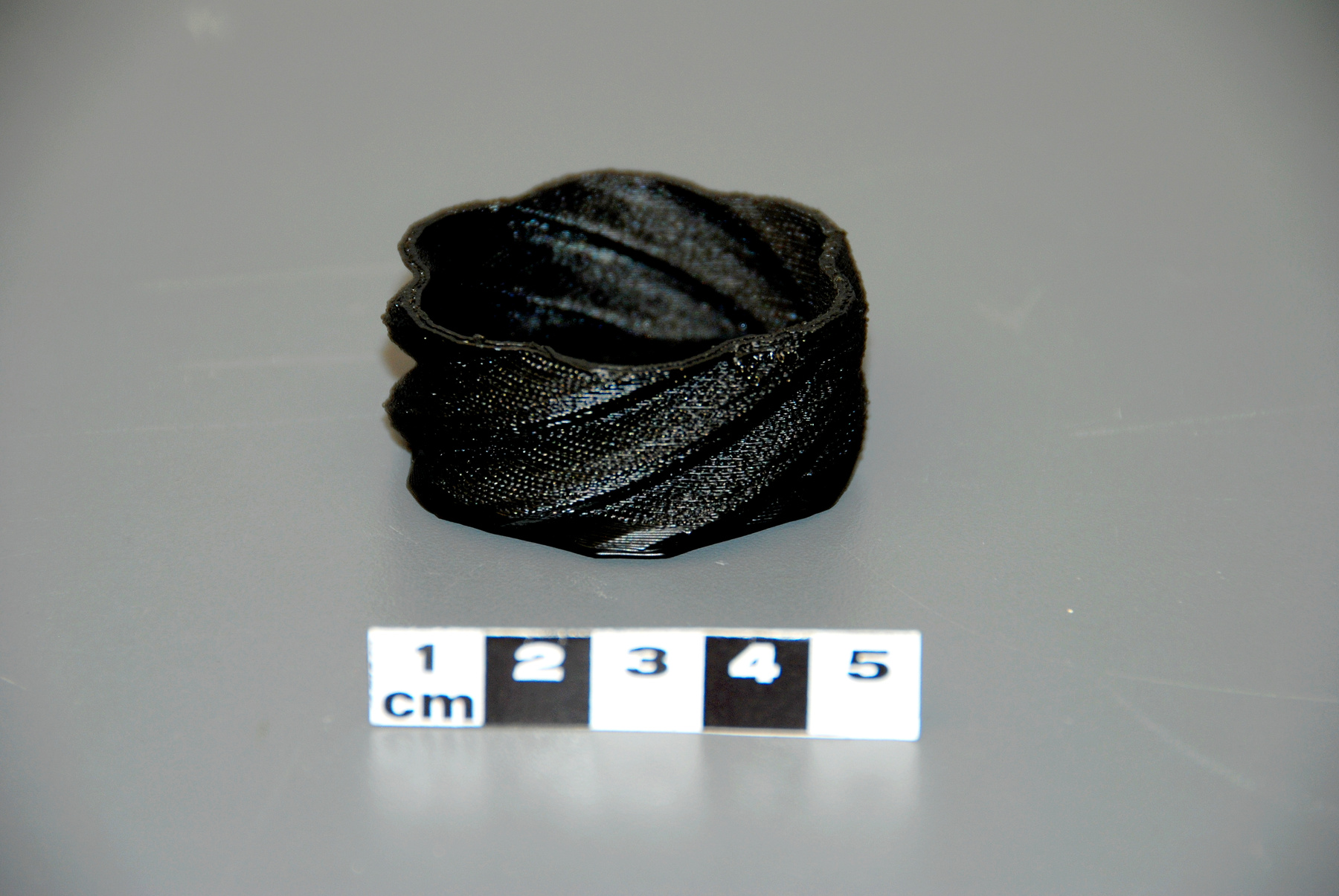

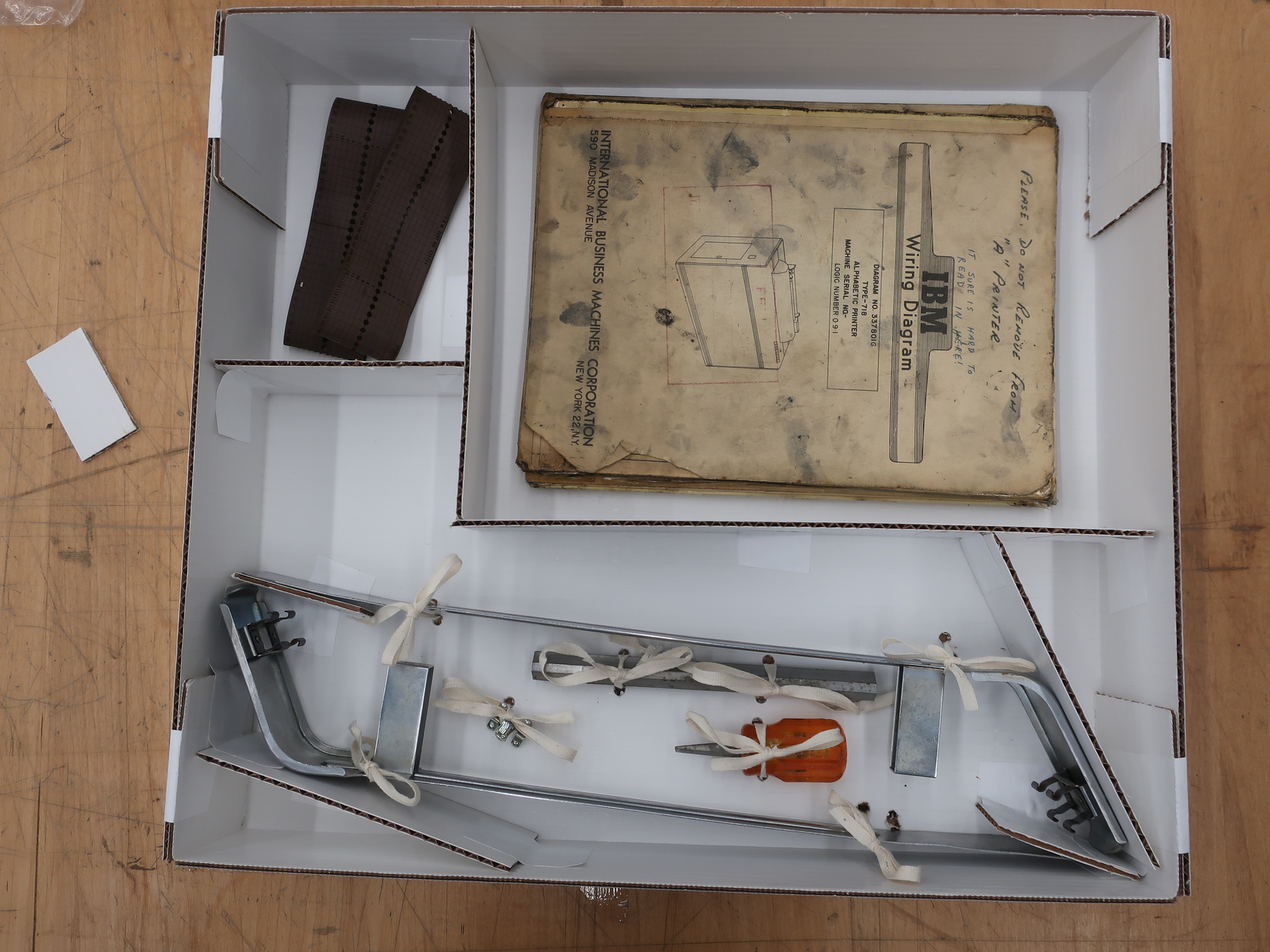

- Tape is made from a polyimide film with a silicone adhesive. ABS tube.

Dimensions

Note: These reflect the general size for storage and are not necessarily representative of the object's true dimensions.

- Length

- 12.0 cm

- Width

- N/A

- Height

- N/A

- Thickness

- N/A

- Weight

- N/A

- Diameter

- 9.2 cm

- Volume

- N/A

Lexicon

- Group

- Computing Technology

- Category

- Digital peripheral devices

- Sub-Category

- N/A

Manufacturer

- AKA

- Unknown

- Country

- Unknown

- State/Province

- Unknown

- City

- Unknown

Context

- Country

- Canada

- State/Province

- Ontario

- Period

- Purchased new by the museum.

- Canada

-

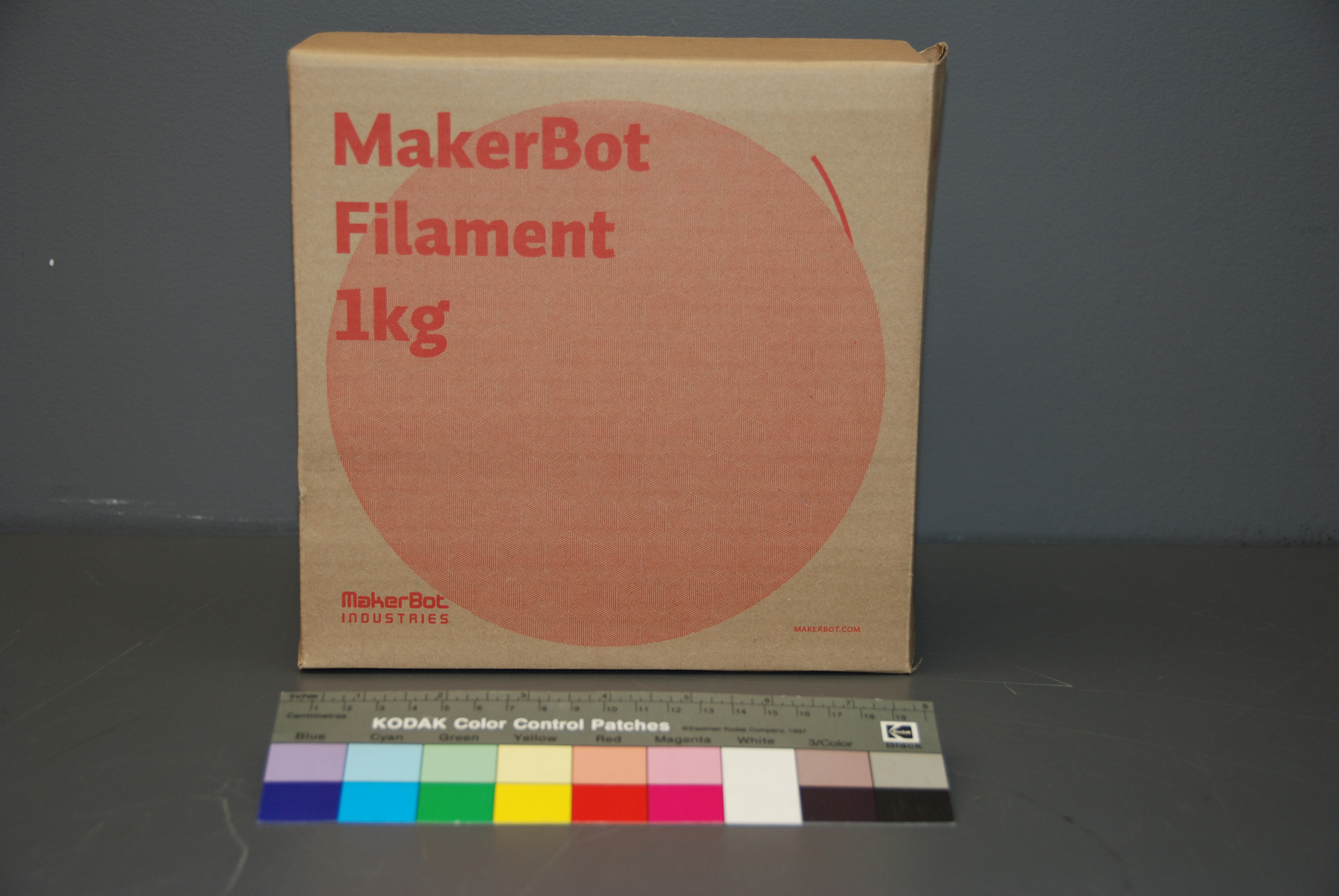

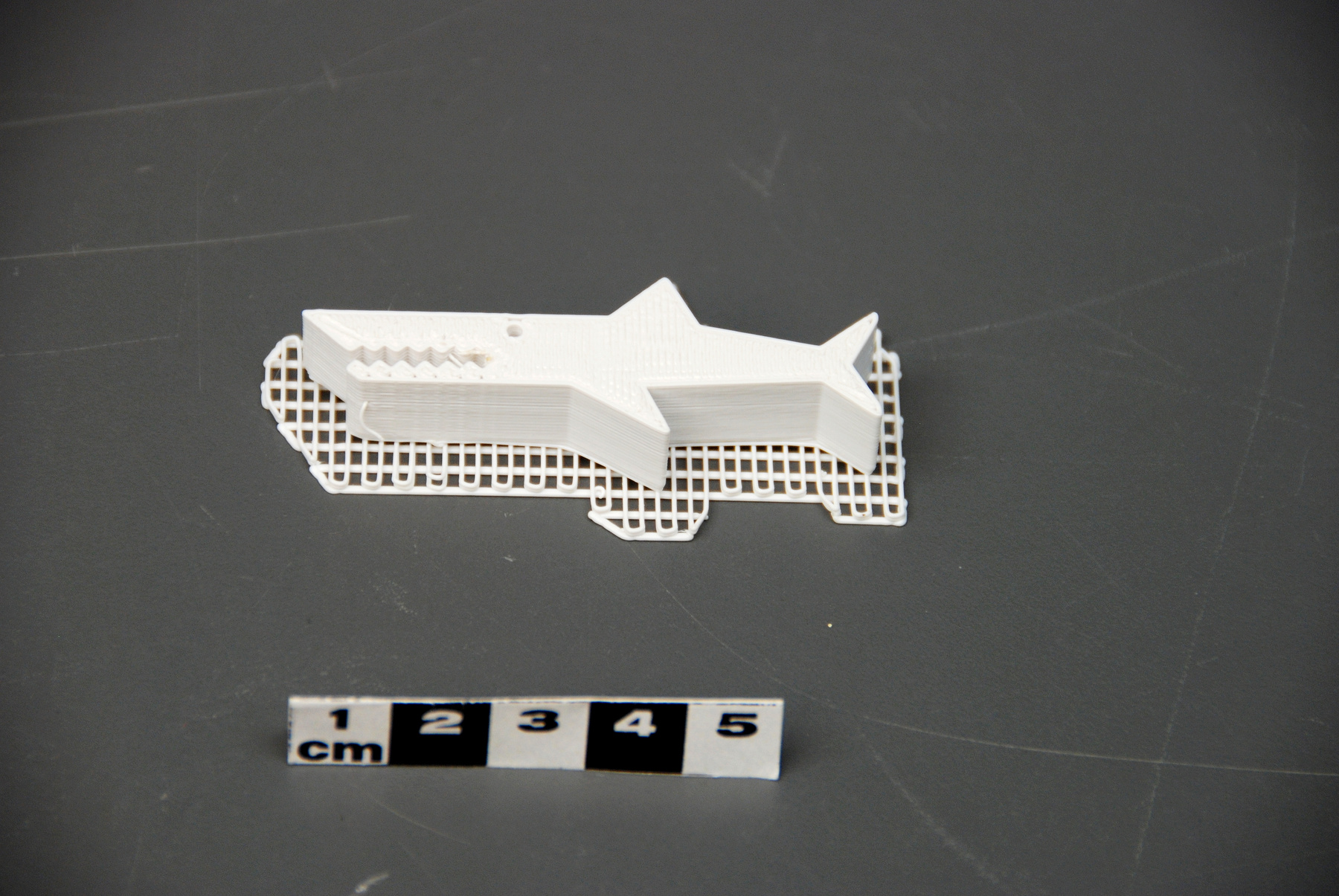

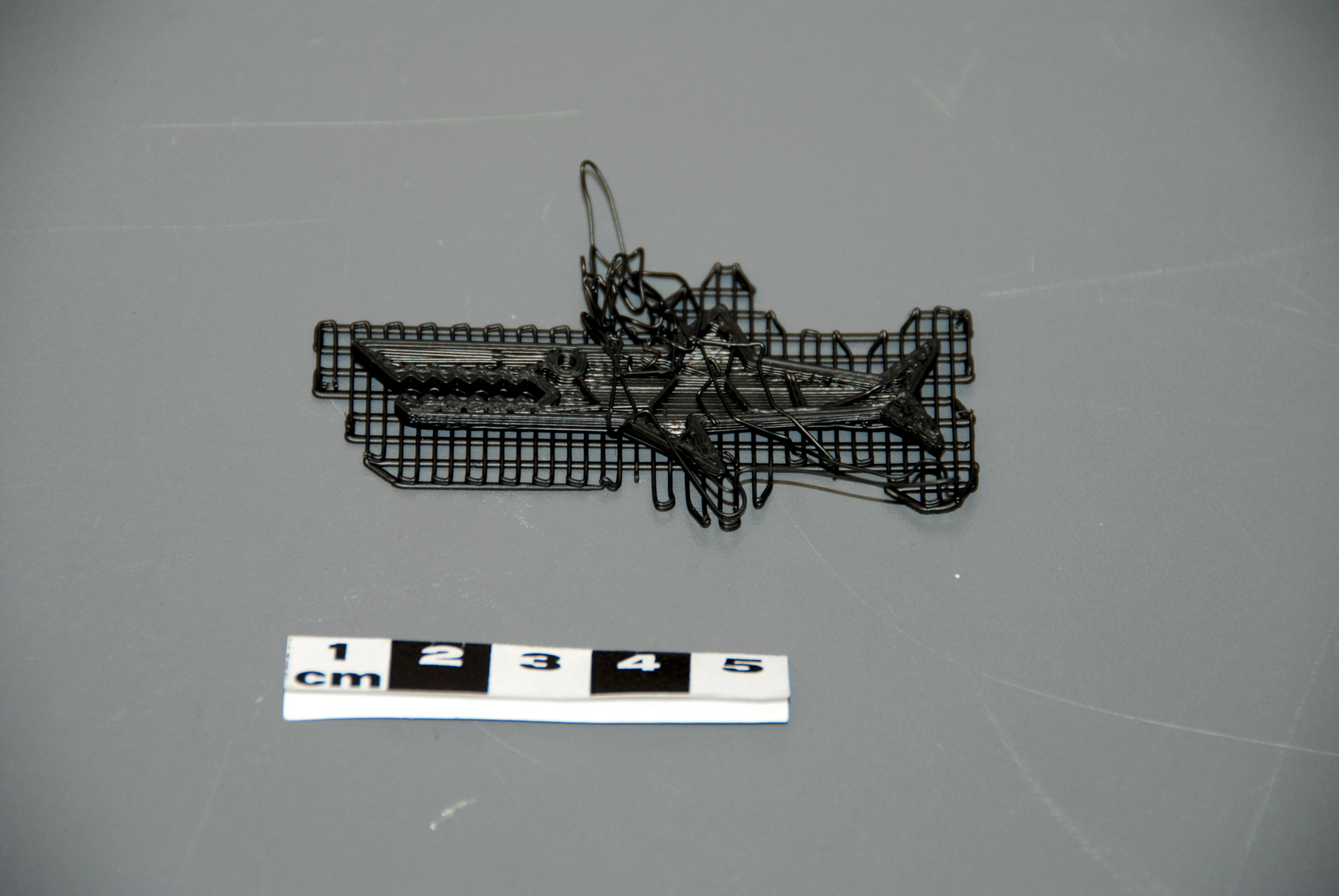

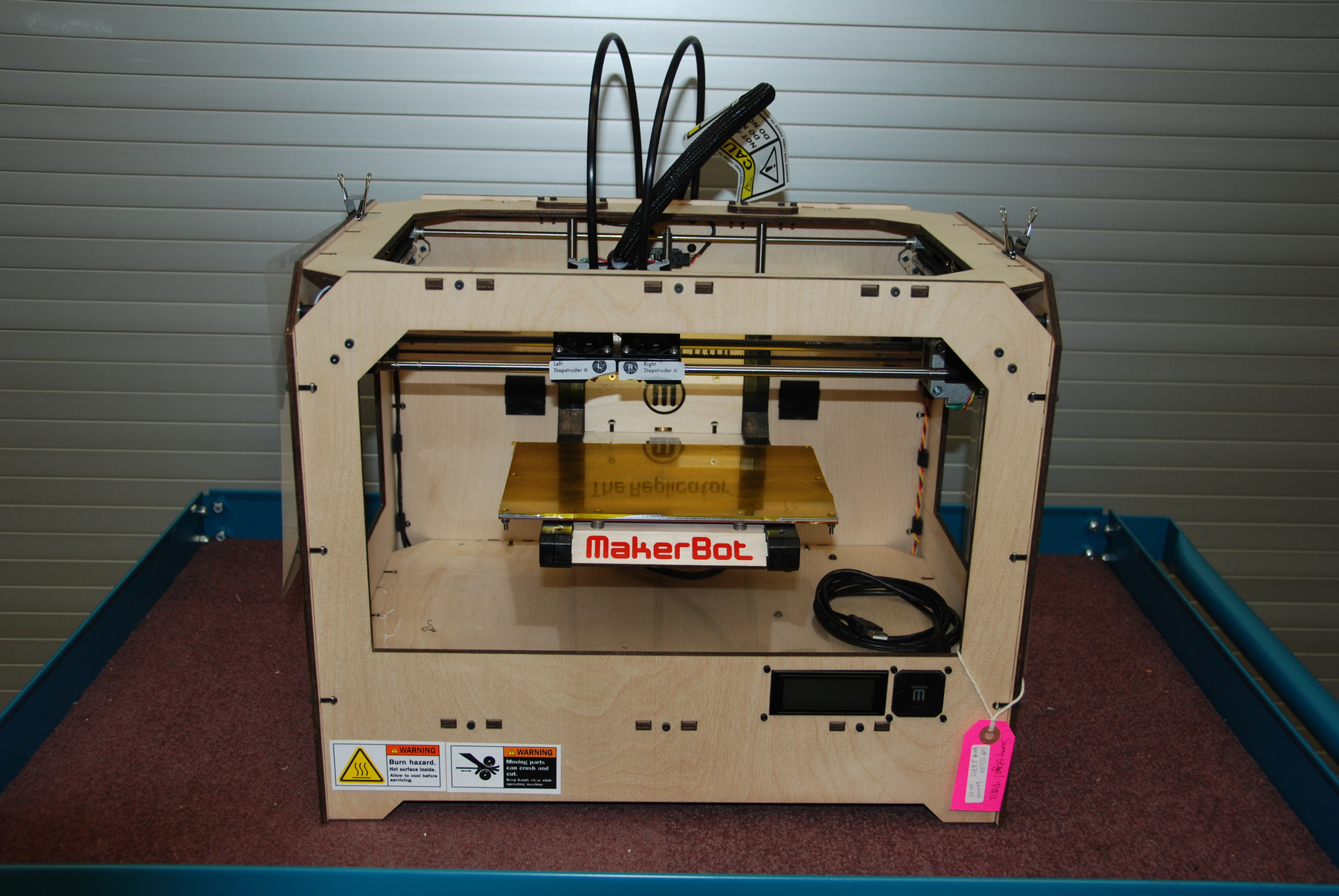

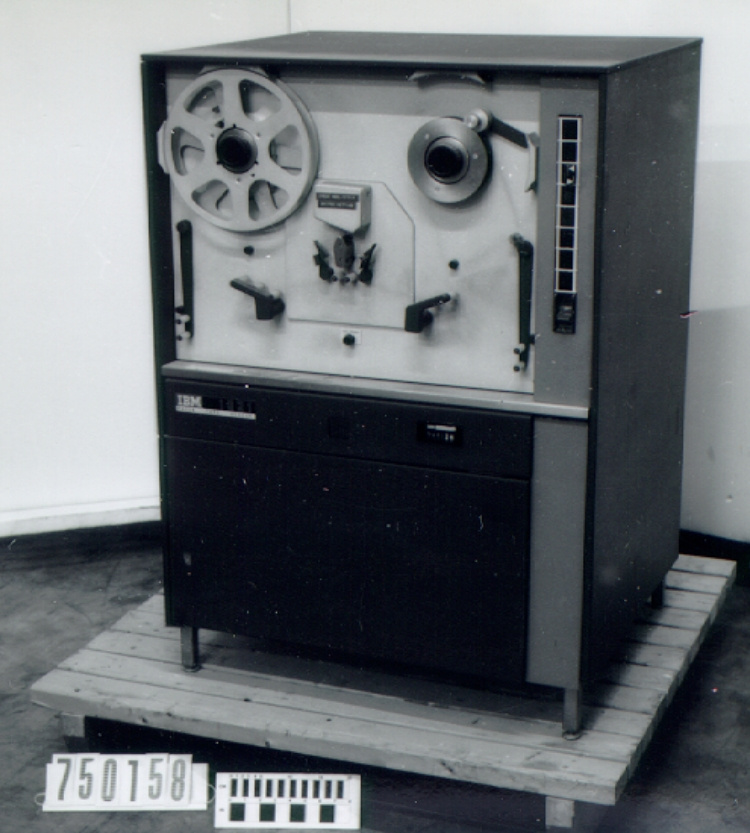

Three dimensional (3D) printers are increasingly used for rapid prototyping and short production runs. - Function

-

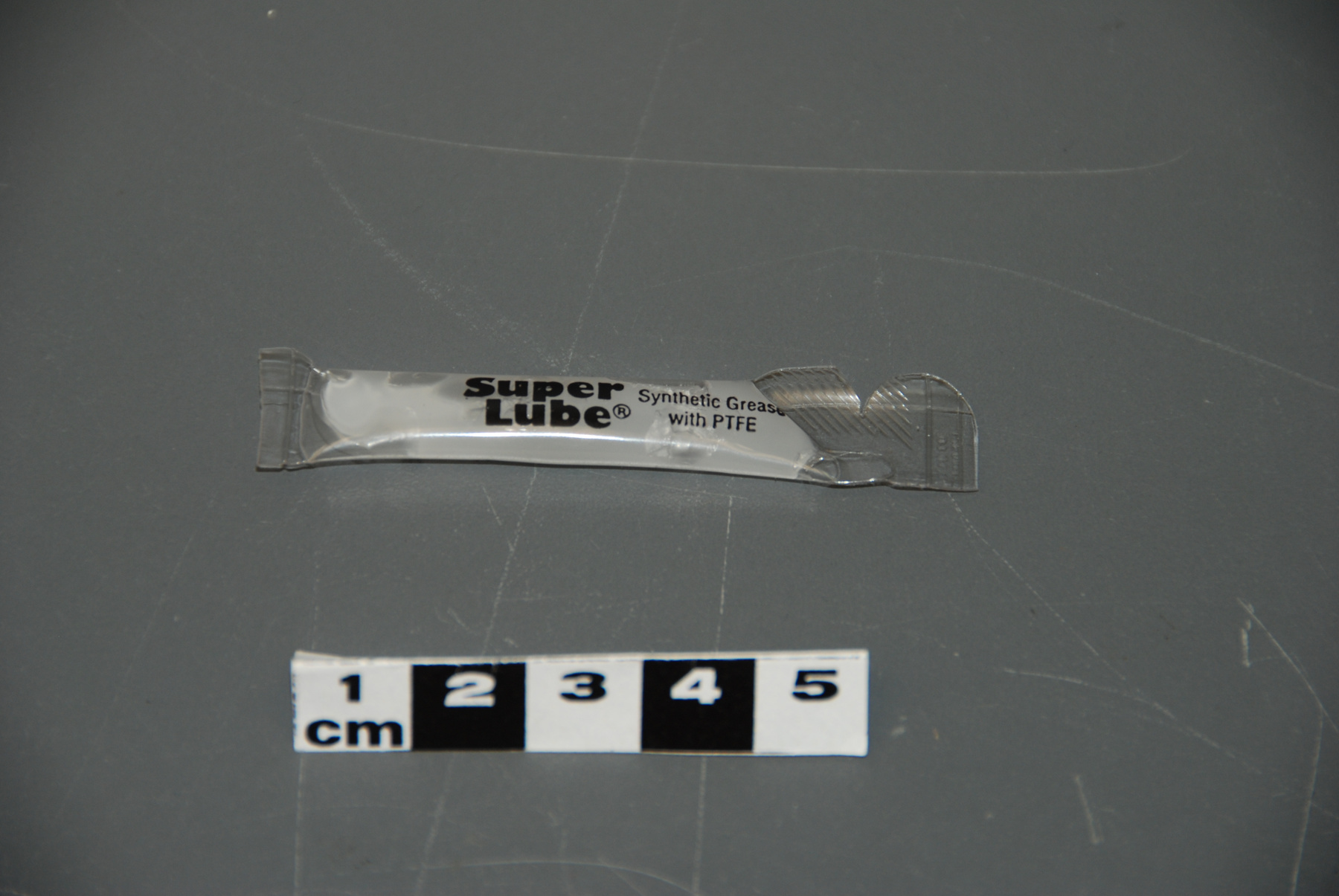

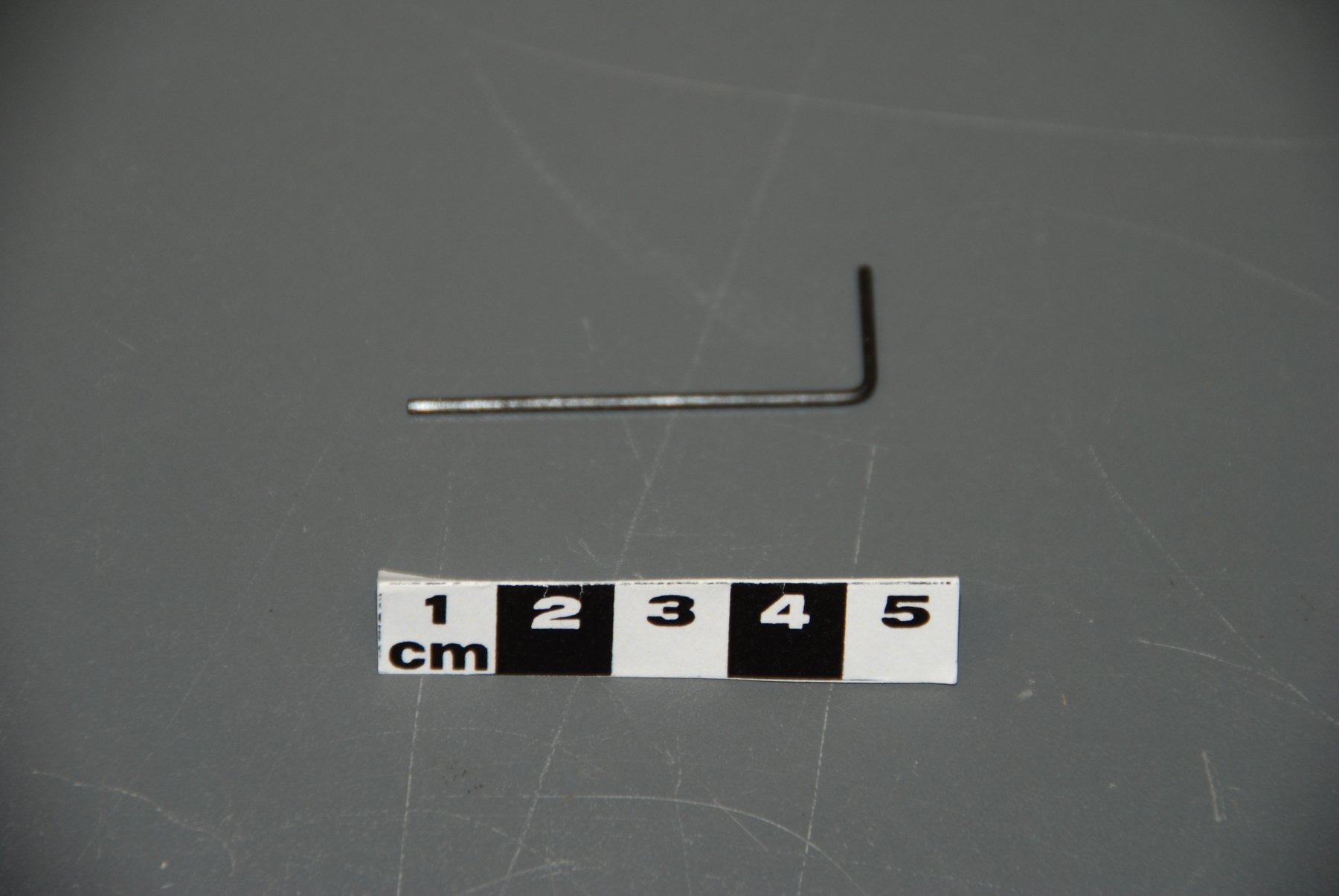

Polyimide film with silicone adhesive used on MakerBot platform. Resistant to high temperature. - Technical

-

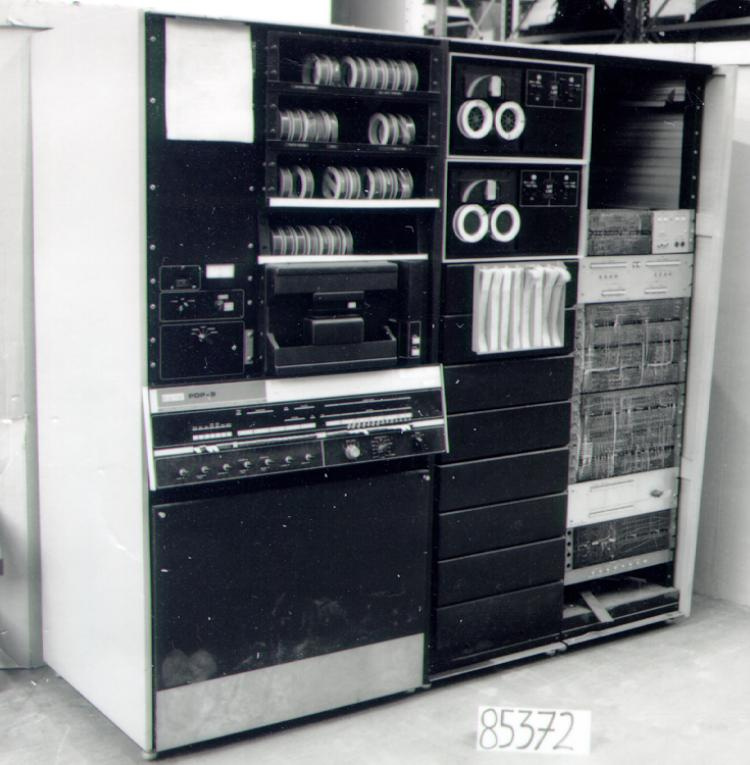

Three dimensional printers make objects through additive processes, whereby successive layers of material are laid down to produce the desired shape. This distinguishes them from devices that employ subtractive processes, where material is removed to essentially sculpt the finished product. In conventional manufacturing, subtractive processes are commonly associated with machine tools, many of which operate automatically from physical templates or digital instructions. Digitally controlled additive manufacturing may be said to have originated with the Jacquard loom, in which punched cards control the arrangement of threads into the final pattern. Moulding machines are a common example of an additive device that uses an analogue model (the pattern and mould) to control the fabrication process. In 3D printing the model is a digital “blueprint” produced using computer aided design (CAD) or animation modelling software. Three dimensional printers were first developed in the late 1970s. A number of techniques have been employed, including extrusion deposition, granular materials binding (laser sintering) and photopolymerization (stereolithography). Before the turn of the century, devices were large, expensive and lacking in versatility. Their use was largely confined to industry. In 1995 MIT graduate students Jim Bredt and Tim Anderson modified an inkjet printer to extrude a binding solution onto a bed of polymer powder, coining the term “3D printing” and winning a patent on their design. In 2005-2006 two open-source projects associated with universities were established that stimulated the spread of low-cost 3D printing into the do-it-yourself, or “maker,” market. Established at Cornell University, Fab@Home released its first device, using a multi-syringe deposition system, in 2006. The RepRap Project, founded by Adrian Bowyer at the University of Bath in 2005, aimed to produce a device that could “print” most of its own components. One of the individuals involved with the RepRap project was Sebastien Bailard, a physicist living in Ottawa. To date, no further information has been found about him. Another Canadian connected to RepRap was Wade Bortz, who in November 2008 was the first person outside the Bath lab to replicate all the printable parts of a RepRap machine. RepRap printers generally employed thermoplastic extruders mounted on a computer-controlled Cartesian XYZ platform. This is the same technology used in the MakerBot Replicator. The Replicator is fed by spools of ABS or PLA (bio-plastic) having a filament diameter of 1.75 mm. It can be configured for one or two nozzles (which allows two-colour printing) and builds up objects in layers of .2-.3 mm at a speed of 40 mm/second. The maximum nozzle temperature is 230 C. The device is controlled through proprietary software, a video game-style control bad and an 80 character LCD screen. It can print from files input from an SD card or USB device. The MakerBot has a print volume of 5 litres, producing objects up to the size of a loaf of bread. - Area Notes

-

Unknown

Details

- Markings

- none

- Missing

- N/A

- Finish

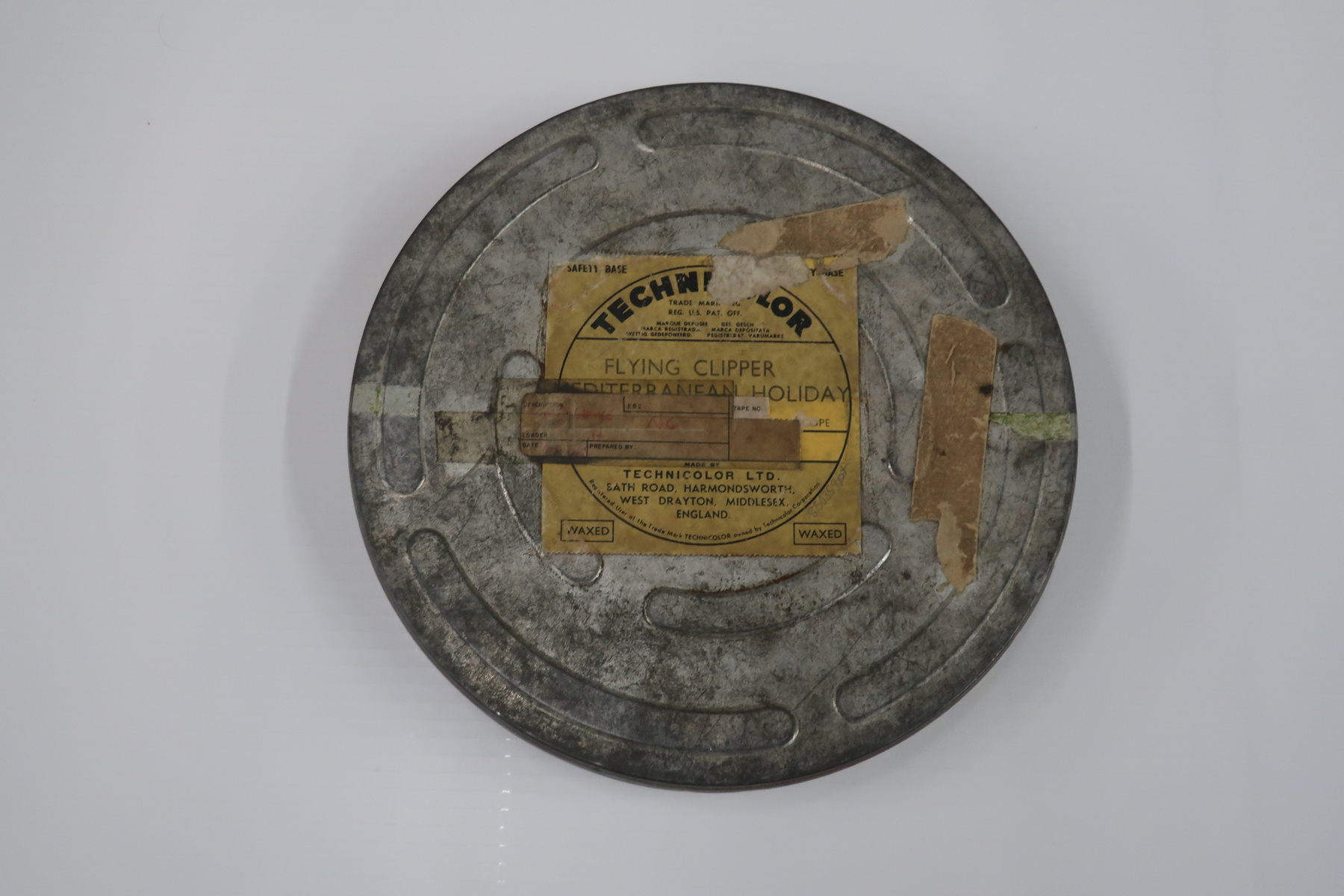

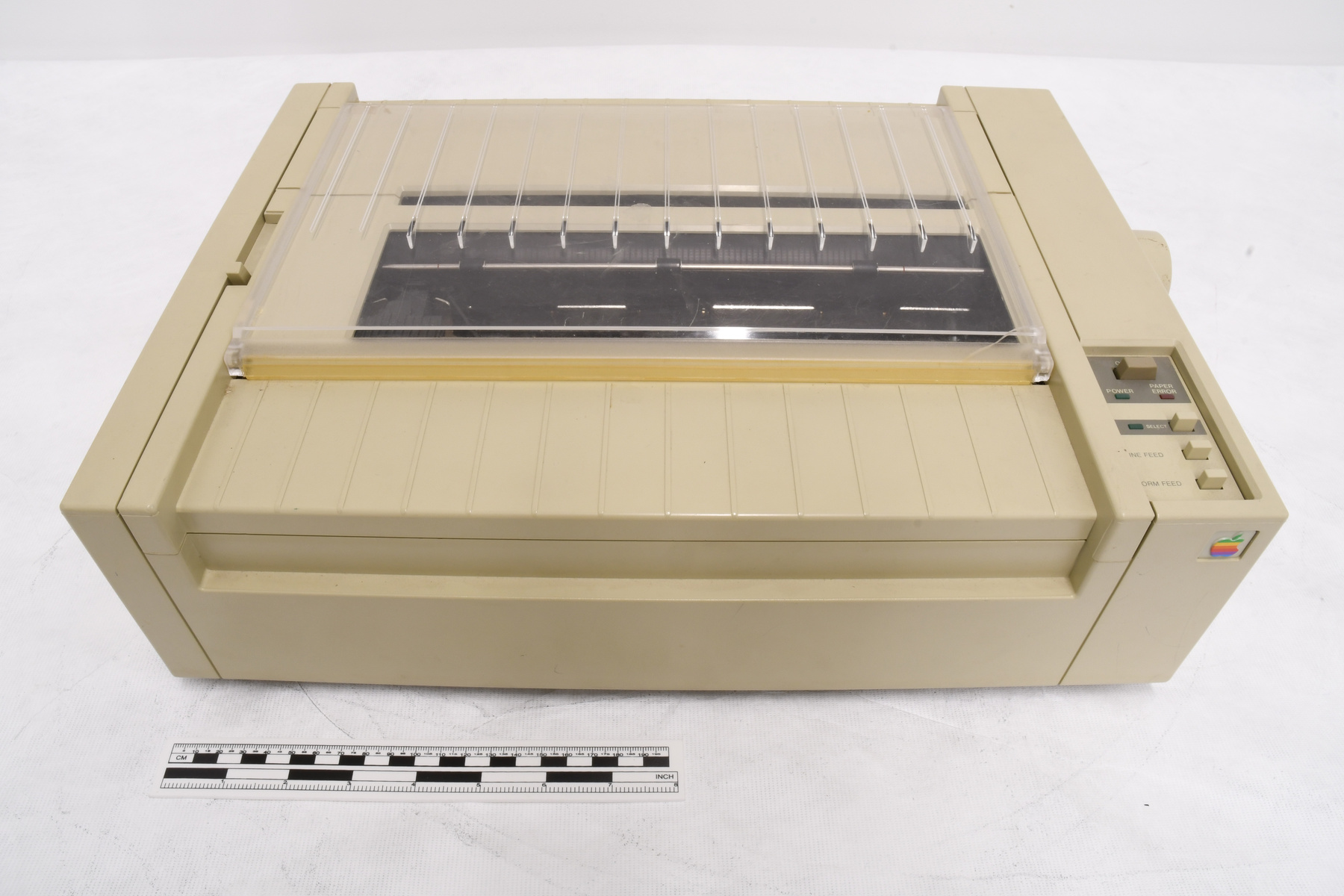

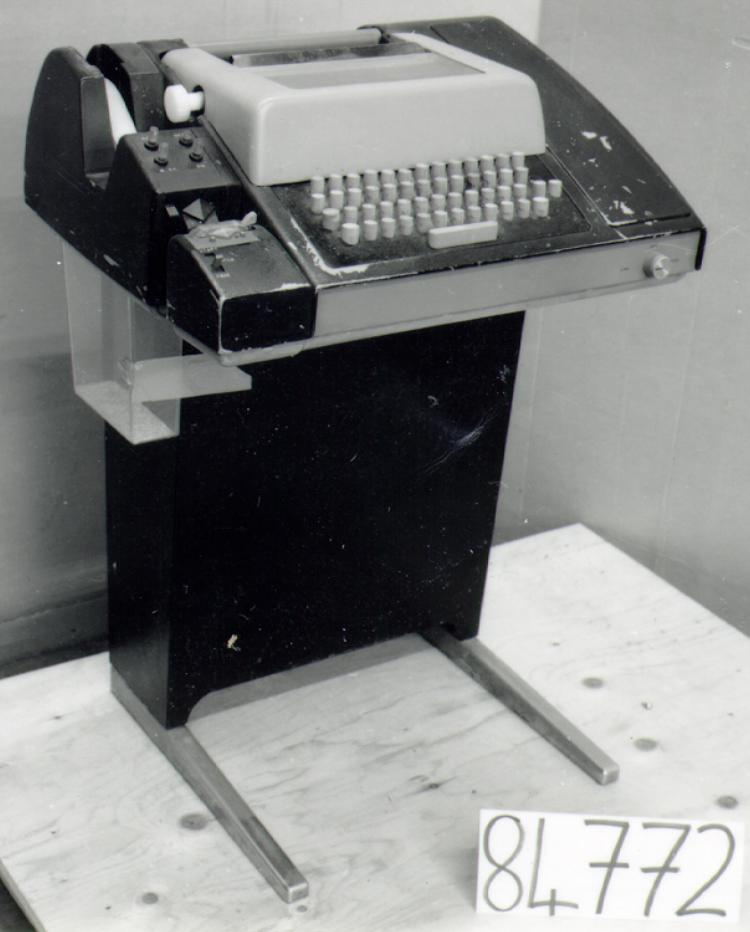

- Brassy coloured tape mounted on a white ABS tube.

- Decoration

- N/A

CITE THIS OBJECT

If you choose to share our information about this collection object, please cite:

Unknown Manufacturer, Tape, adhesive, 2012, Artifact no. 2013.0097, Ingenium – Canada’s Museums of Science and Innovation, http://collections.ingeniumcanada.org/en/item/2013.0097.011/

FEEDBACK

Submit a question or comment about this artifact.

More Like This