Simulator, flight impact

Use this image

Can I reuse this image without permission? Yes

Object images on the Ingenium Collection’s portal have the following Creative Commons license:

Copyright Ingenium / CC BY-NC-ND (Attribution-NonCommercial 4.0 International (CC BY-NC 4.0)

ATTRIBUTE THIS IMAGE

Ingenium,

2013.0140.001

Permalink:

Ingenium is releasing this image under the Creative Commons licensing framework, and encourages downloading and reuse for non-commercial purposes. Please acknowledge Ingenium and cite the artifact number.

DOWNLOAD IMAGEPURCHASE THIS IMAGE

This image is free for non-commercial use.

For commercial use, please consult our Reproduction Fees and contact us to purchase the image.

- OBJECT TYPE

- N/A

- DATE

- 1965–1972

- ARTIFACT NUMBER

- 2013.0140.001

- MANUFACTURER

- NRC, Div. of Mechanical Engineering, Engine Laboratory

- MODEL

- EL-3

- LOCATION

- Ottawa, Ontario, Canada

More Information

General Information

- Serial #

- Prototype

- Part Number

- 1

- Total Parts

- 6

- AKA

- chicken cannon; chicken gun; rooster rocket

- Patents

- N/A

- General Description

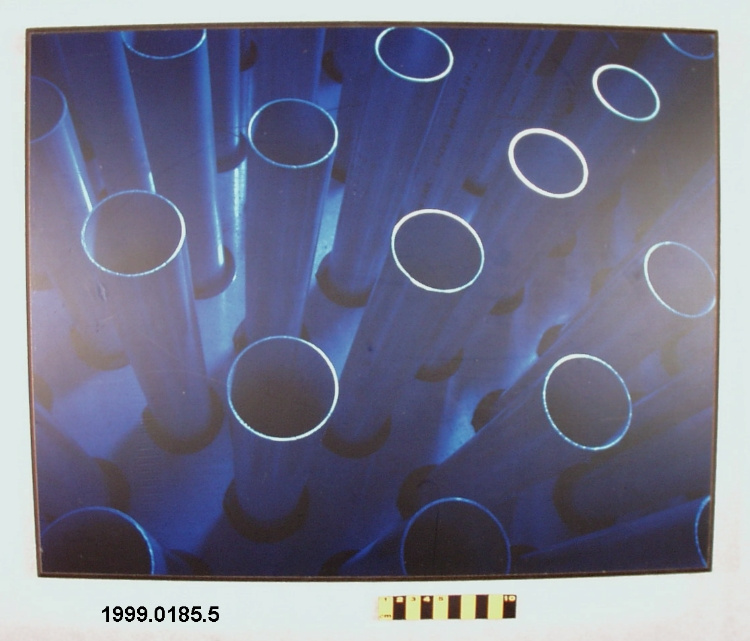

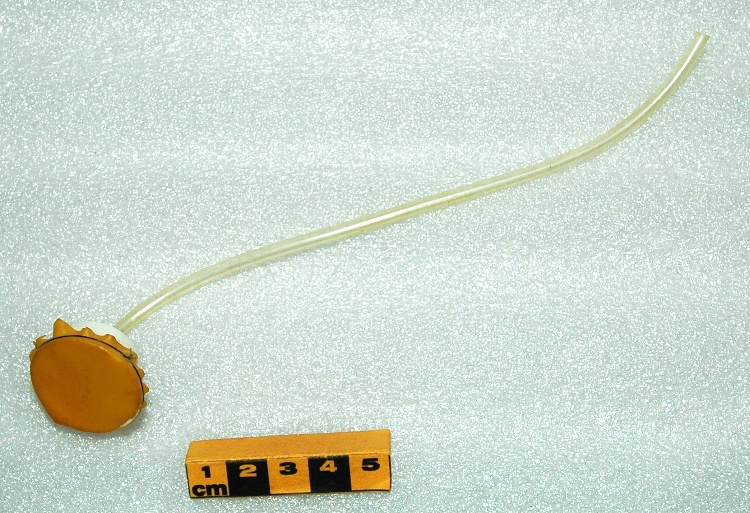

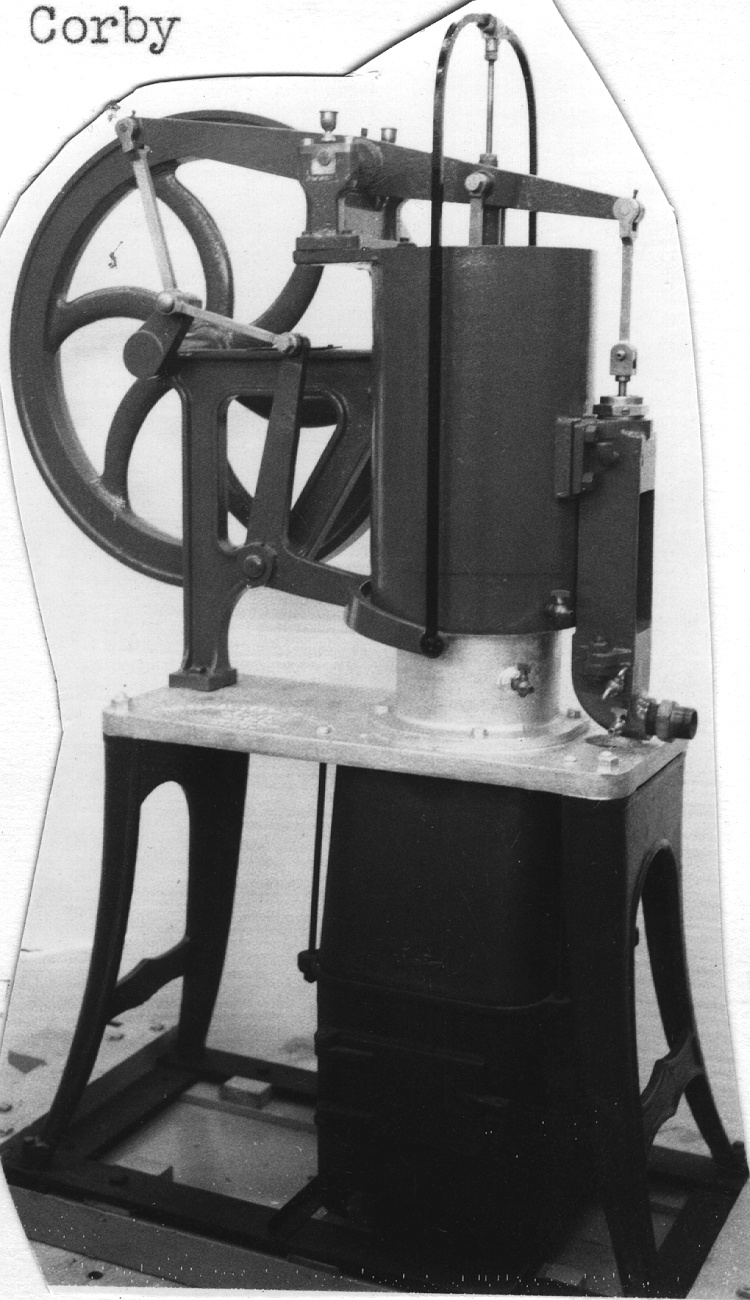

- Single length of silver metal barrel; mounted on metal frame painted blue.

Dimensions

Note: These reflect the general size for storage and are not necessarily representative of the object's true dimensions.

- Length

- 500.0 cm

- Width

- 58.0 cm

- Height

- 170.0 cm

- Thickness

- N/A

- Weight

- N/A

- Diameter

- N/A

- Volume

- N/A

Lexicon

- Group

- Aviation

- Category

- Research

- Sub-Category

- N/A

Manufacturer

- AKA

- NRC

- Country

- Canada

- State/Province

- Ontario

- City

- Ottawa

Context

- Country

- Canada

- State/Province

- Ontario

- Period

- c. 1972- 2010.

- Canada

-

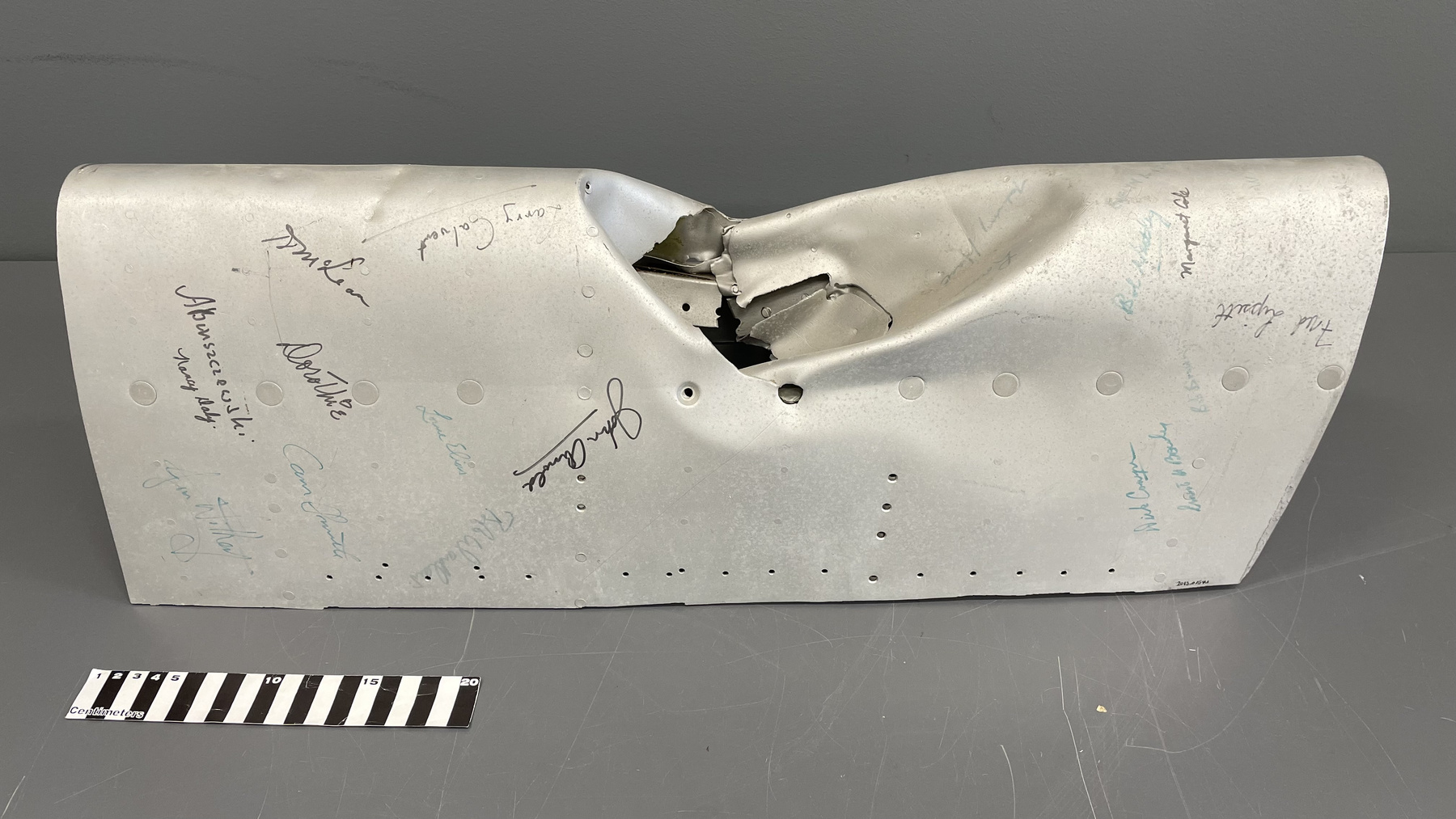

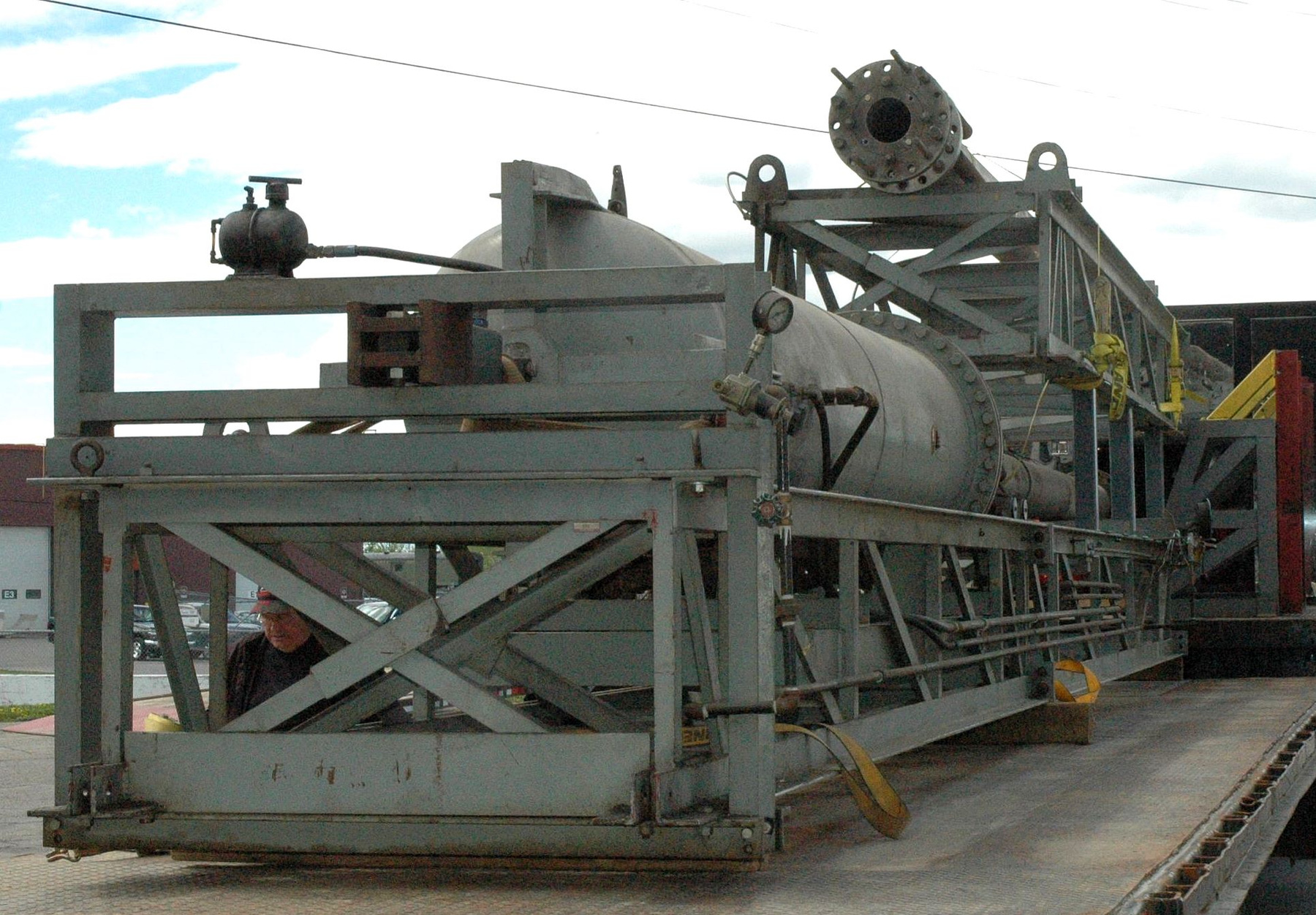

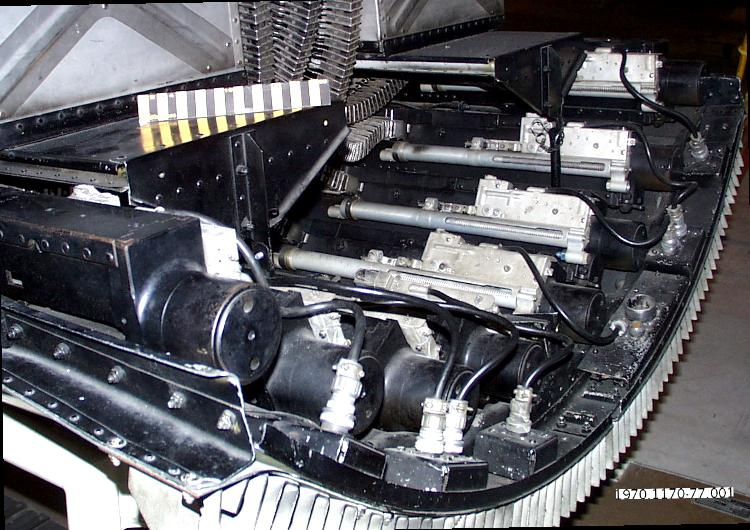

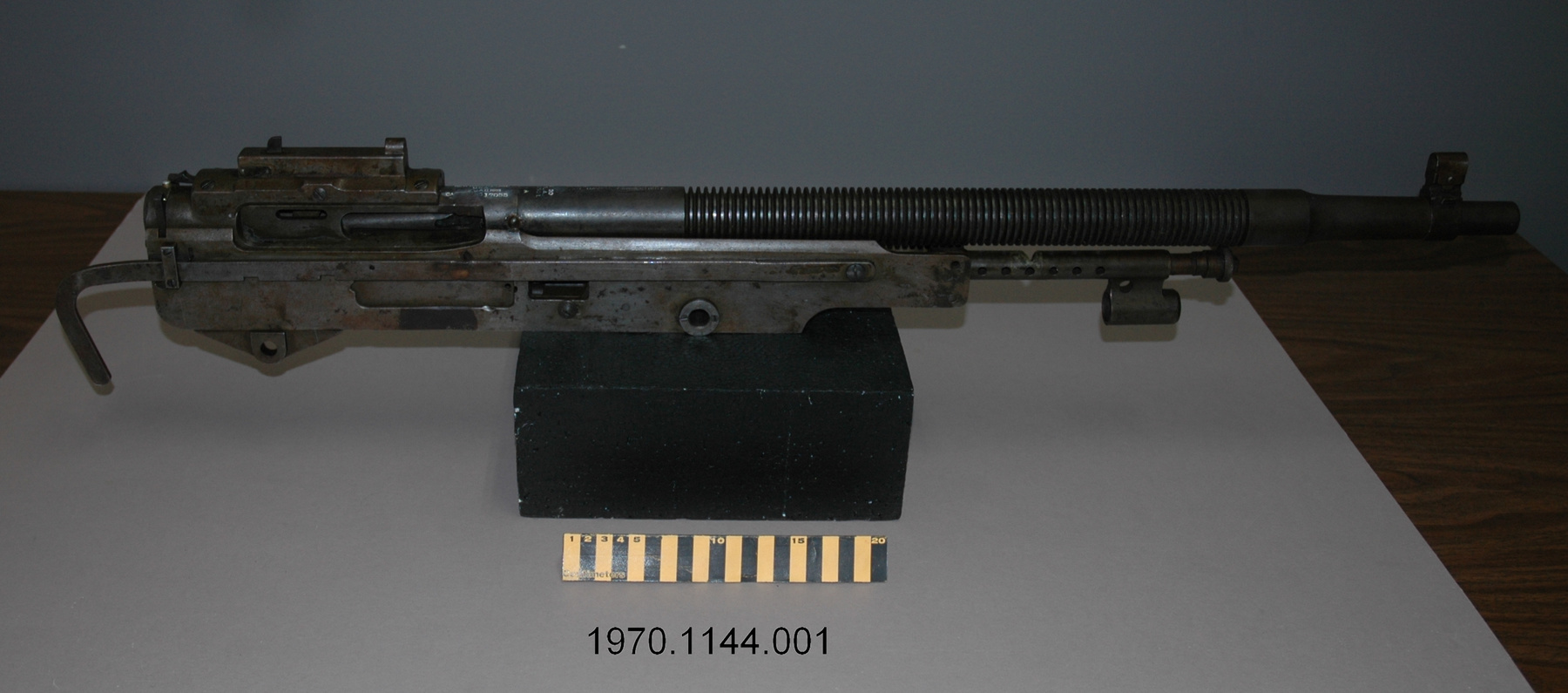

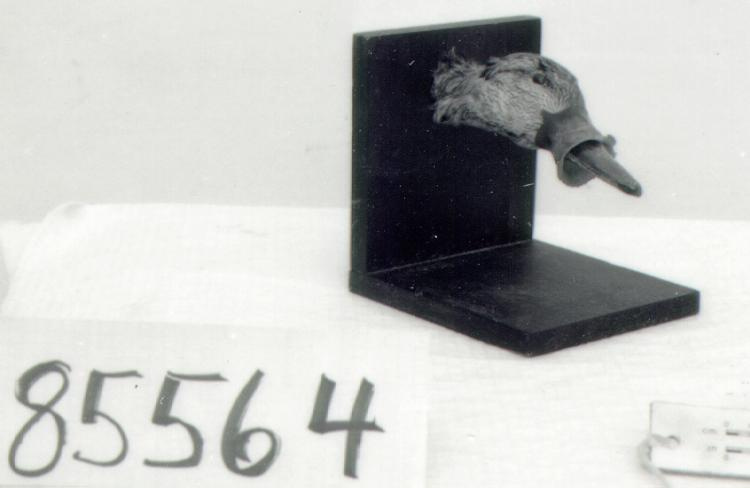

Canada’s first fully functional flight impact simulator. National Research Council of Canada has been using flight impact simulators [FIS] for almost half a century. Indeed, few organisations on this Earth have been involved in bird strike testing longer than NRC. NRC has played a crucial role in making flying safer. It is very likely, if not almost certain, that the flight impact simulators located in Ottawa were the inspiration for the Chicken Cannon irregularly put to use on the CBC’s weekly television show Royal Canadian Air Farce. The Chicken Cannon made its appearance on Friday, March 4th, 1994. It was apparently last fired on Thursday, December 18th or Friday, December 19th, 2008, at the taping of the show’s very popular New Year’s special. Throughout the years, the Chicken Cannon was loaded and fired by one of the show’s most popular character, Colonel “Teresa” Stacey, played by Don Ferguson. As well as a sizeable number of rubber chickens, the Chicken Cannon fired a bewildering variety of items, primarily food, at photos of individuals, either Canadian or foreign, who were deemed to be the most annoying at the time. Viewers proposed many targets. [Ref. 1] - Function

-

Used to test aircraft components to see if they could resist the impact of one or more birds. - Technical

-

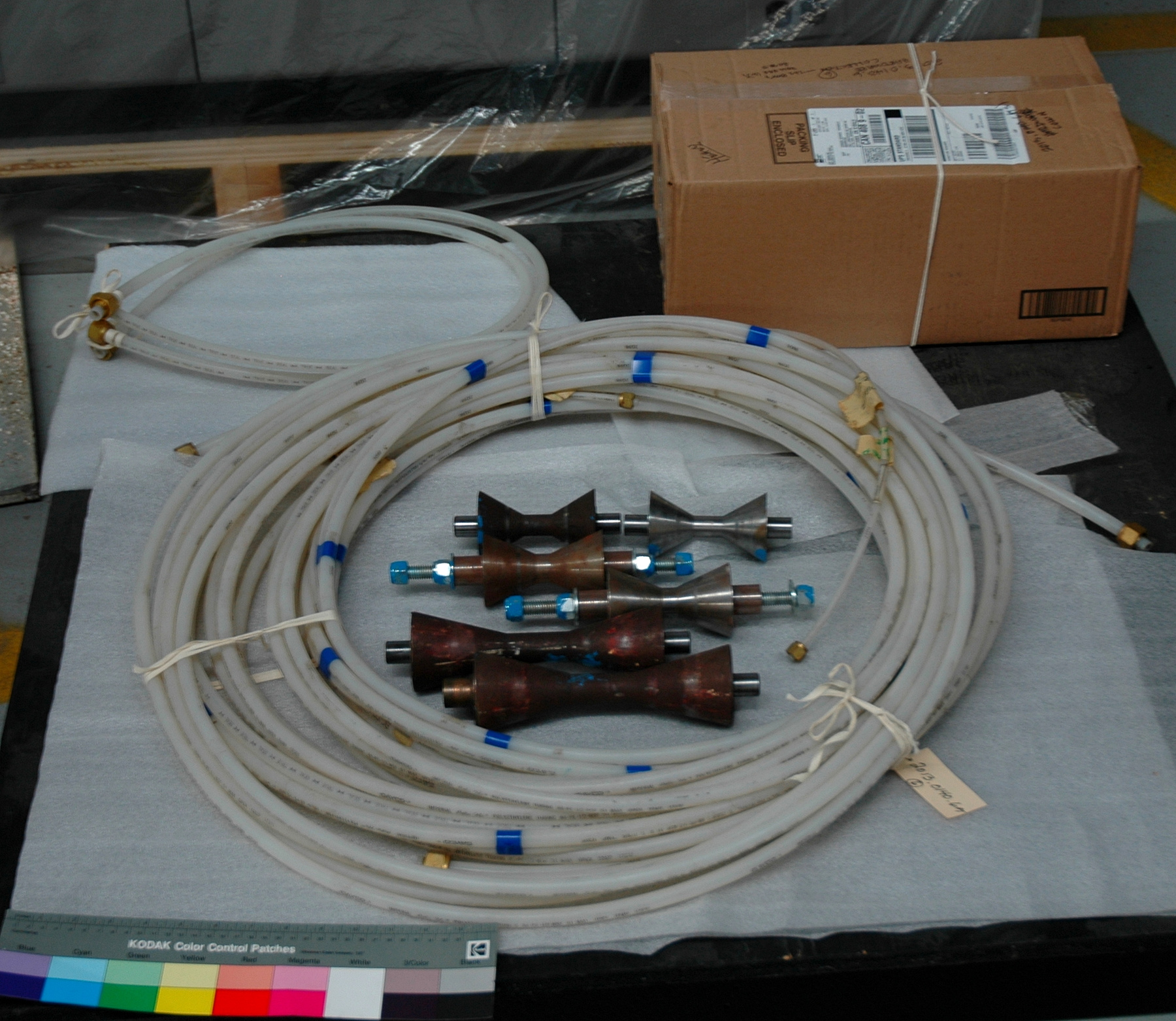

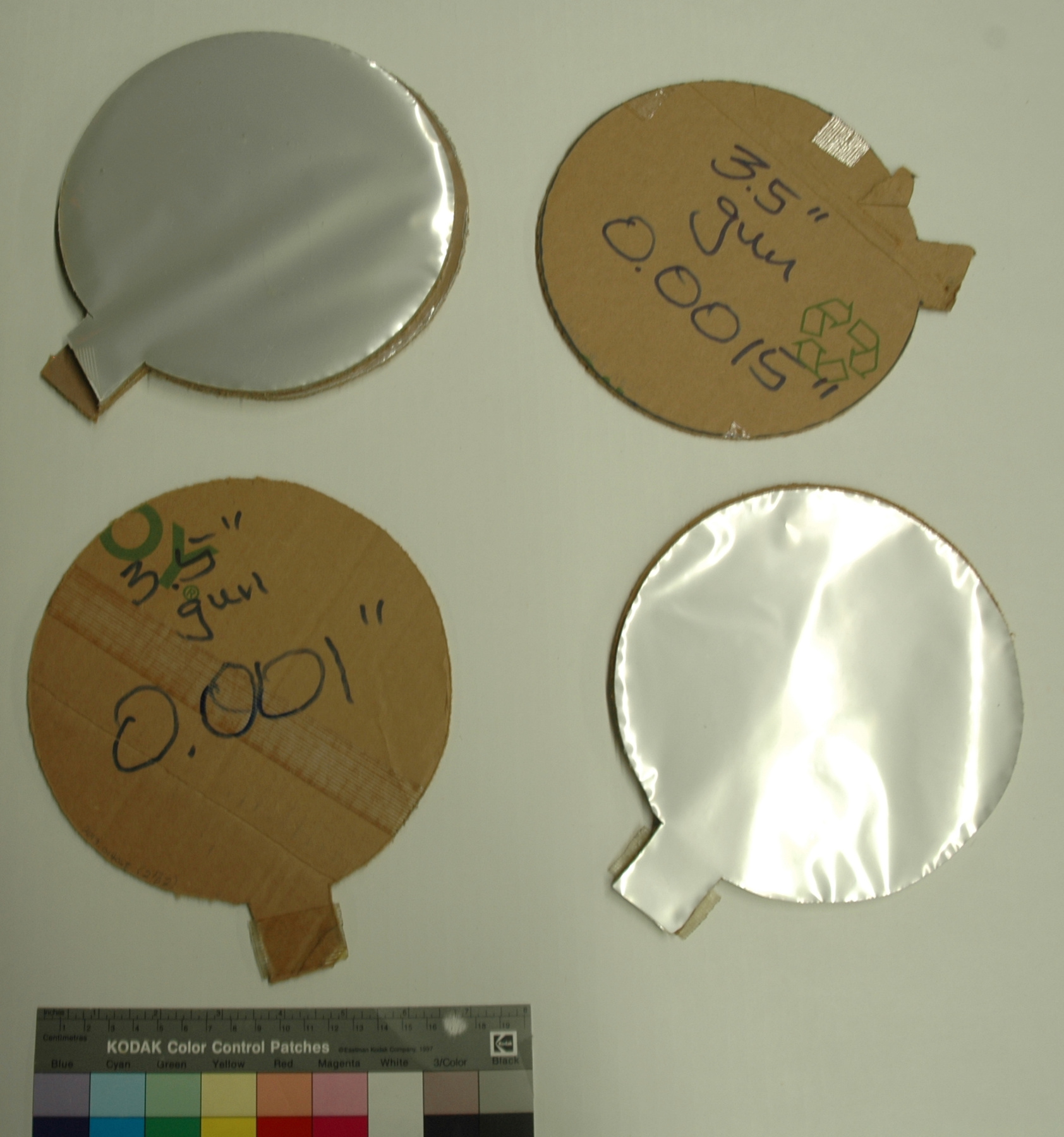

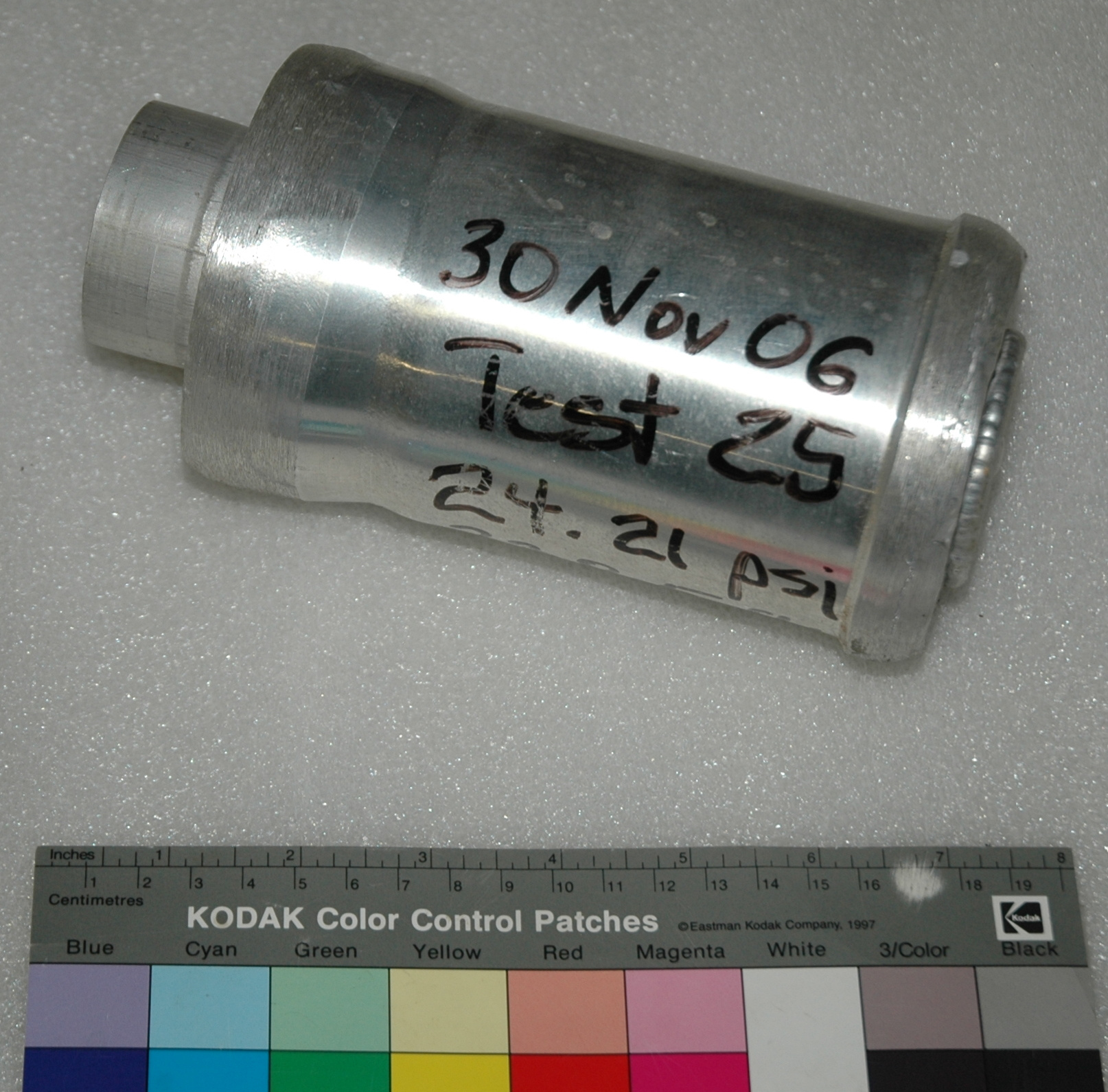

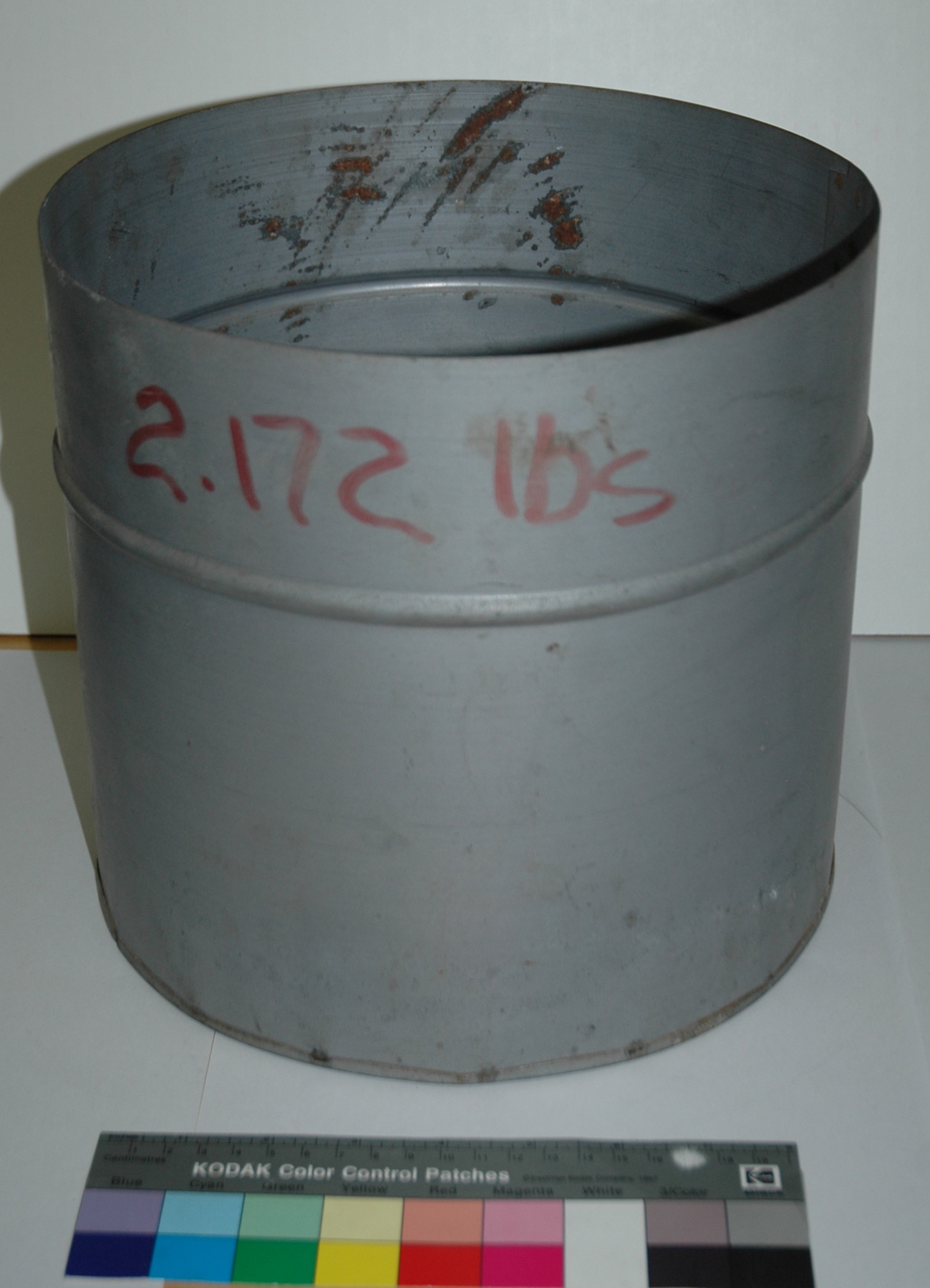

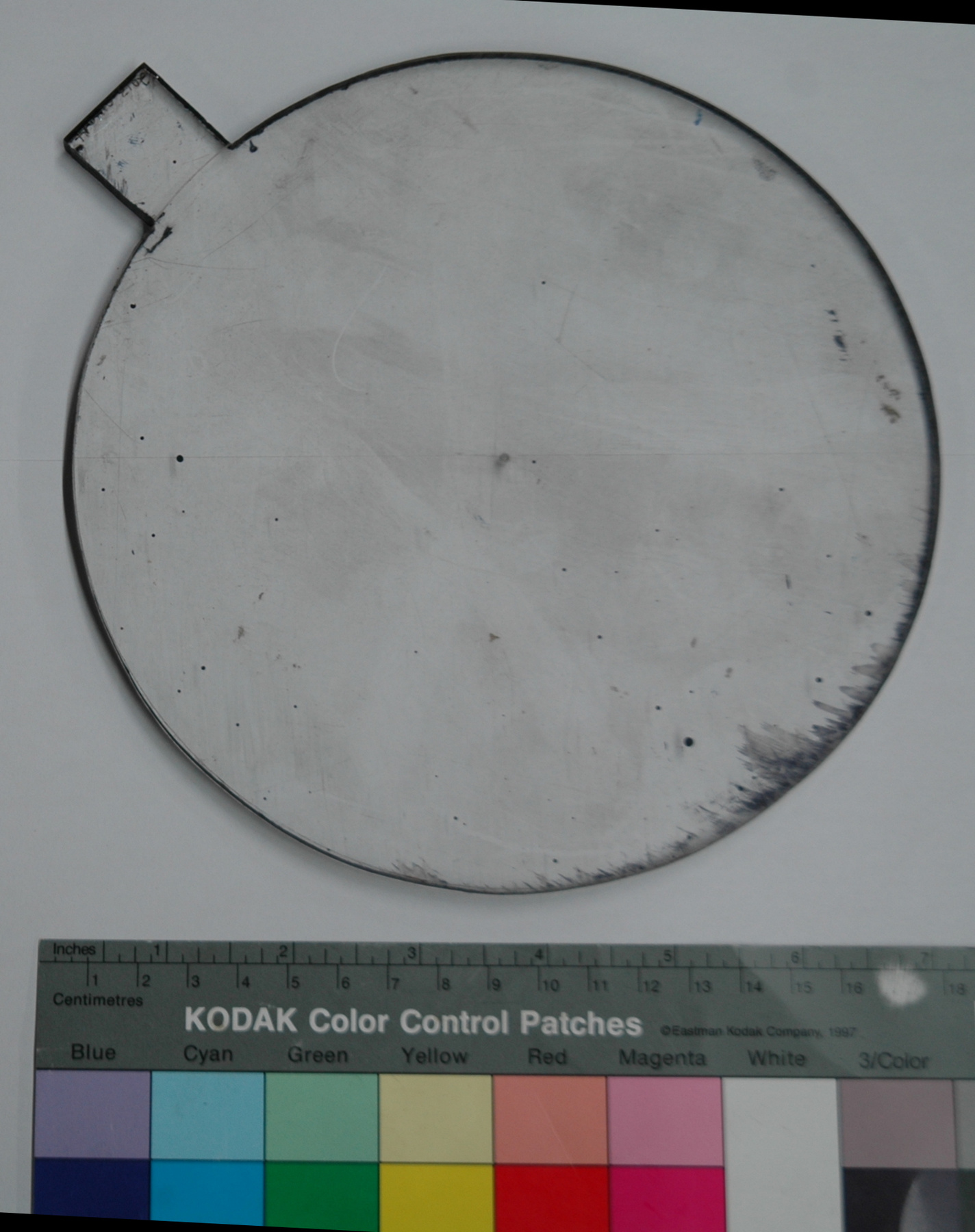

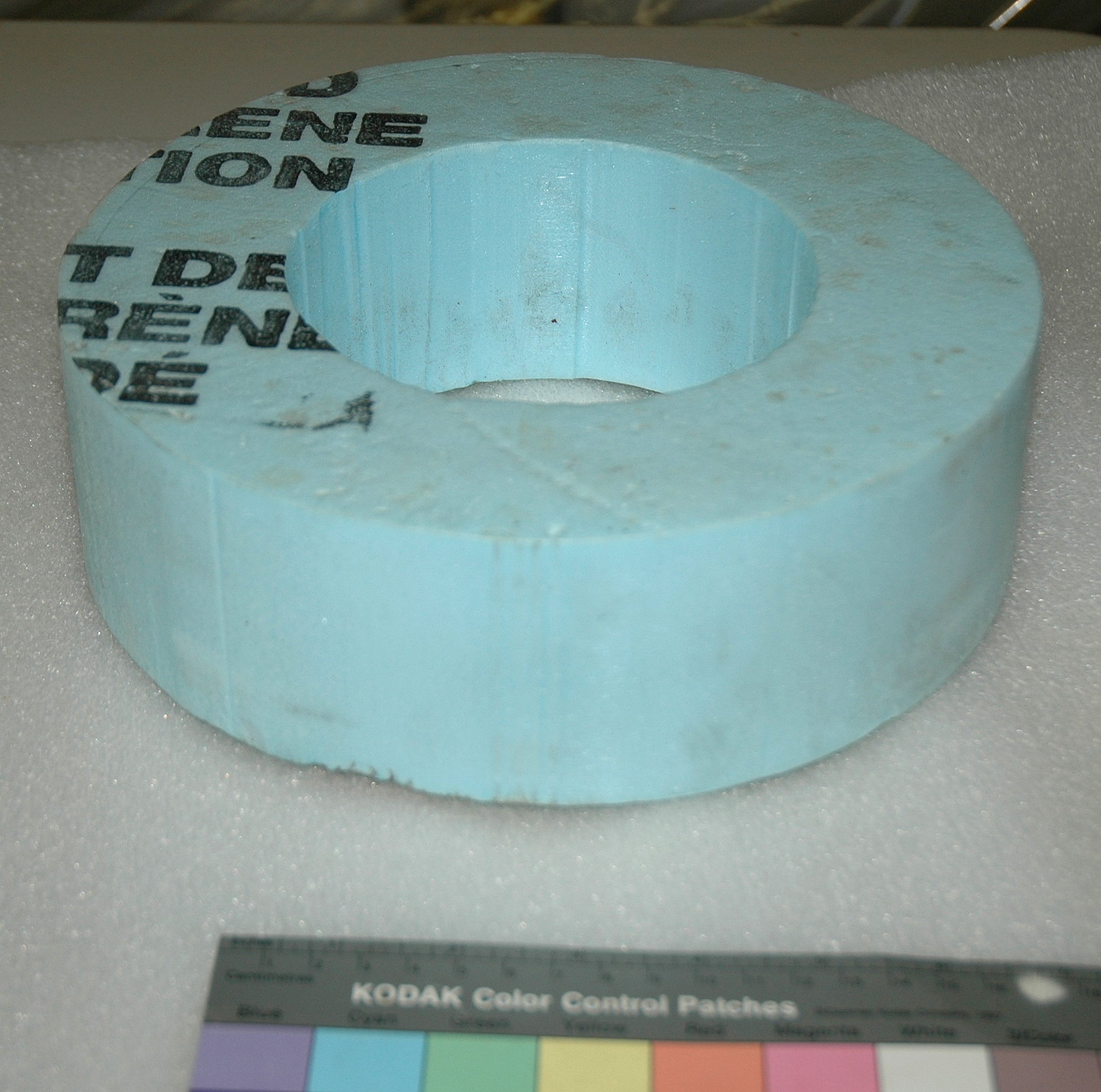

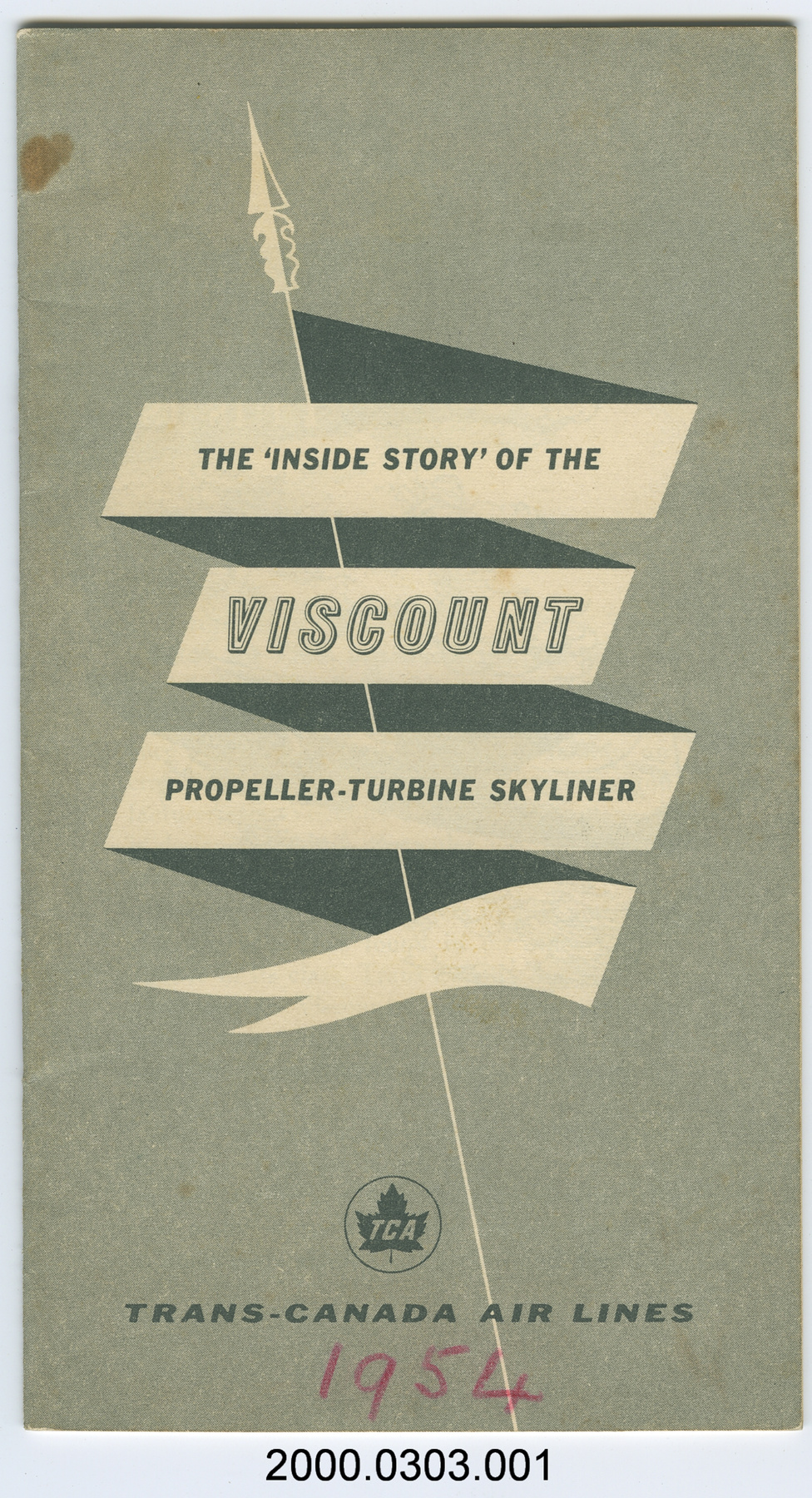

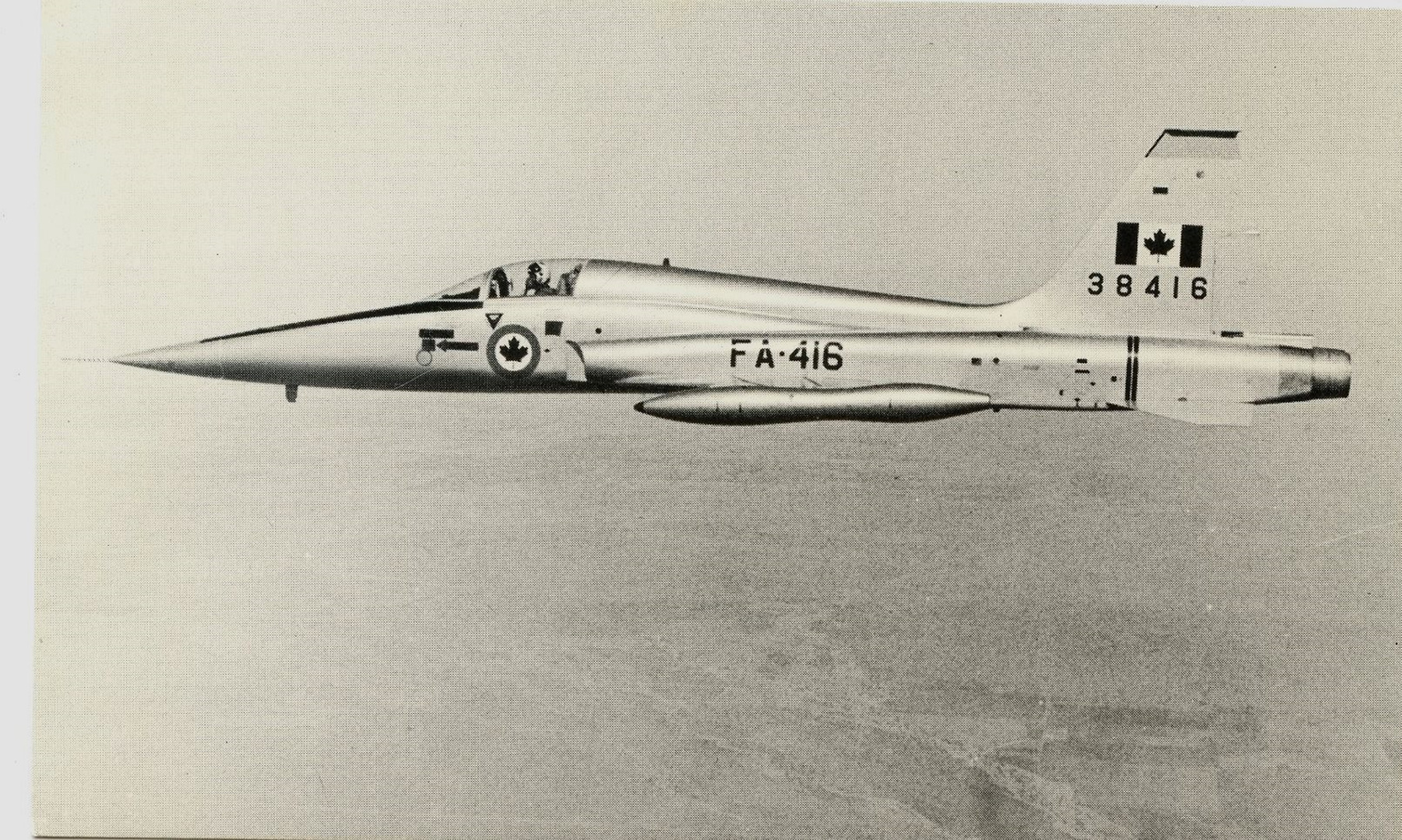

The 3.5-inch flight impact simulator (FIS) is the oldest surviving FIS in the world. It was officially retired in 2010, after 45 years of service. Also known, in its early days, as the 3.75-inch gun, it had a 3.65-metre smooth¬bore brass barrel and a 95-mm bore. This device could fire fully feathered birds weighing up to 2 lb. (910 grams). The 3.75-inch gun was apparently built to conduct impact tests on the tailplane / tail assembly of the Vickers Viscount turboprop airliner, a type of aircraft operated by Trans-Canada Air Lines / Air Canada and numerous other airlines around the world. The reason behind this interest was the crash of a United Air Lines Viscount on Friday, November 23rd, 1962. As it flew over Maryland at an altitude of 1 800 m, the airliner ran into a flock of migrating swans. One of the two birds that hit the airliner damaged the port / left horizontal stabiliser to such an extent that it quickly broke off. The crew lost control of the aircraft. The Viscount fell near Ellicott City, west of Baltimore. All 17 people on board died. This tragedy was instrumental in pushing through a requirement that the tailplane / tail assembly of airliners be able to resist the impact of an 8-lb. (3.6 kg) bird . In late 1971, the 3.75-inch gun came to the Structures and Materials Laboratory of the National Aeronautical Establishment (NAE), an independent division of the NRC based in Ottawa, on Montreal Road, with facilities at Uplands, near Ottawa . It was at that point that it joined the much larger 10-inch gun [2013.0141]. In late 1971 or early 1972, the 3.75-inch gun was fitted with a new 3.65-metre stainless steel smoothbore barrel with an 89-mm bore. It was known from then on as the 3.5-in gun. The basic operating principle of the 3.5-inch gun differed slightly from that of the 3.75-in gun. As was the case in the past, a fully feathered bird was put in a container / barrel plug, or sabot, prior to firing. The barrel of the gun was also moved away from the compressed air reservoir so that the loaded sabot could be put inside the barrel. This time around, two thin circular diaphragms capable of resisting slightly more than half of the air pressure in the reservoir were inserted to create a step chamber, or breech. The reservoir was separated from the step chamber by the inner or no. 1 diaphragm while the outer or no. 2 diaphragm separated the step chamber from the sabot containing the bird. Both diaphragms were originally made of aluminium alloy but, as their bursting characteristics proved somewhat unreliable, the team looked for a substitute material. By the late summer of 1968, it had chosen Mylar Polyester. One to three sheets were used for each diaphragm. The double diaphragm firing mechanism made it possible to achieve consistent firing speeds test after test, a crucially important factor in testing and one that customers needed / demanded . With the pressure between the diaphragms adjusted to half the air pressure in the compressed air reservoir, all the operator had to do was press the firing button on the gun control panel [2013.0142]. A quick action valve let out the pressure between the diaphragms. The one separating the reservoir from the step chamber failed, followed very quickly by the other. The suddenly released air hit the loaded sabot and pushed it down the barrel. The sabot was caught at the muzzle of the barrel by a spring-operated sabot catcher informally known as the stripper to ensure that only the bird hit the target. An adjustable hydraulic shock absorber now took care of the gun’s recoil. The 3.5-inch gun was kept in a building at all times . The 3.5-inch gun also fired dummy 20-mm shells and 25-mm steel balls at military aircraft windshields in order to improve their design. The main threats here were presumably projectiles rather than birds. Toward the end of its career, the device fired fully feathered birds into running gas turbine engines and human-made hailstones at panels made of composite materials. By and large, these particular tests were conducted on behalf of foreign customers. The 3.5-inch gun also played a limited role in the development of the two modern flight impact simulators currently operated by the NRC’s Institute for Aerospace Research (IAR), or NRC Aerospace. [Ref. 1] - Area Notes

-

Unknown

Details

- Markings

- Not accessible at time of cataloguing.

- Missing

- Incomplete.

- Finish

- Single length of silver metal barrel; mounted on metal frame painted blue.

- Decoration

- N/A

CITE THIS OBJECT

If you choose to share our information about this collection object, please cite:

NRC, Div. of Mechanical Engineering, Engine Laboratory, Simulator, flight impact, between 1965–1972, Artifact no. 2013.0140, Ingenium – Canada’s Museums of Science and Innovation, http://collections.ingeniumcanada.org/en/item/2013.0140.001/

FEEDBACK

Submit a question or comment about this artifact.

More Like This