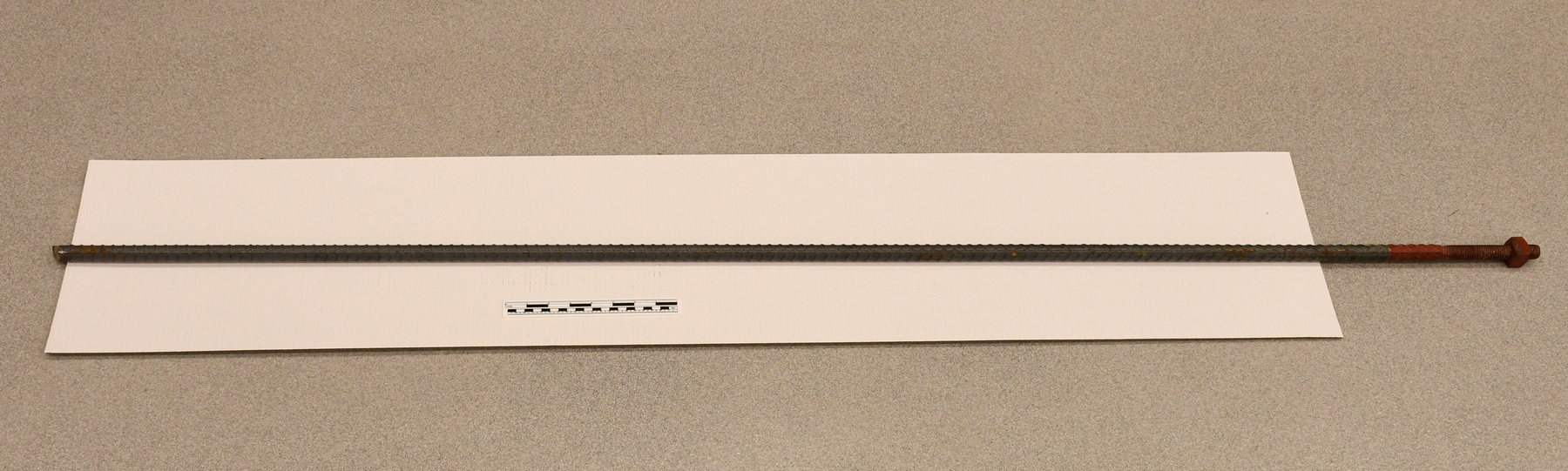

Cable

Use this image

Can I reuse this image without permission? Yes

Object images on the Ingenium Collection’s portal have the following Creative Commons license:

Copyright Ingenium / CC BY-NC-ND (Attribution-NonCommercial 4.0 International (CC BY-NC 4.0)

ATTRIBUTE THIS IMAGE

Ingenium,

2017.0055.005

Permalink:

Ingenium is releasing this image under the Creative Commons licensing framework, and encourages downloading and reuse for non-commercial purposes. Please acknowledge Ingenium and cite the artifact number.

DOWNLOAD IMAGEPURCHASE THIS IMAGE

This image is free for non-commercial use.

For commercial use, please consult our Reproduction Fees and contact us to purchase the image.

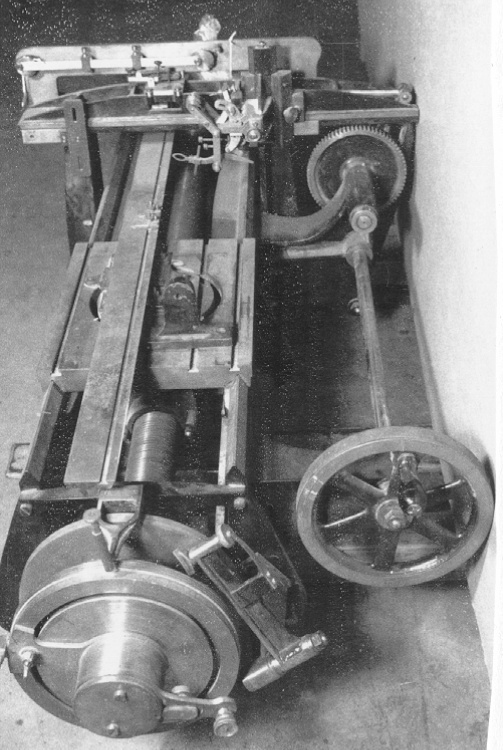

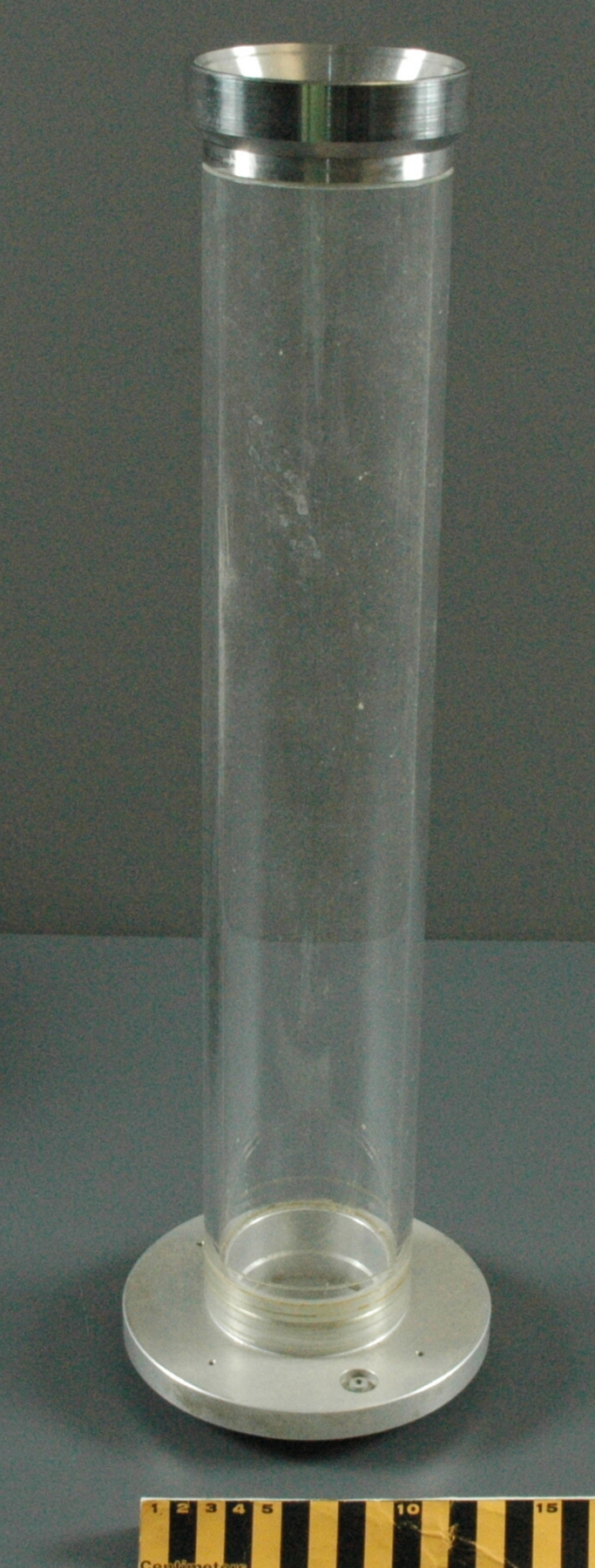

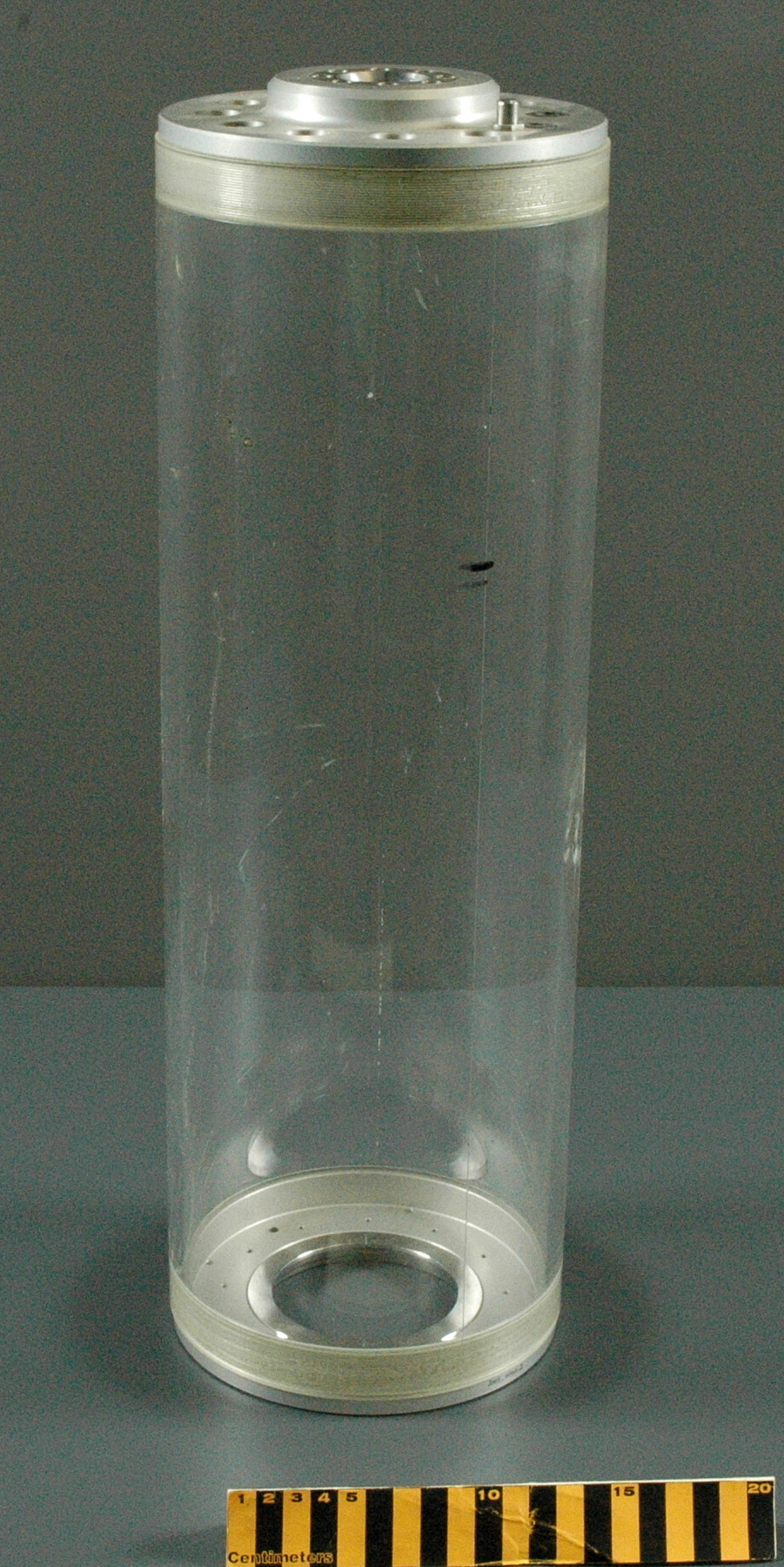

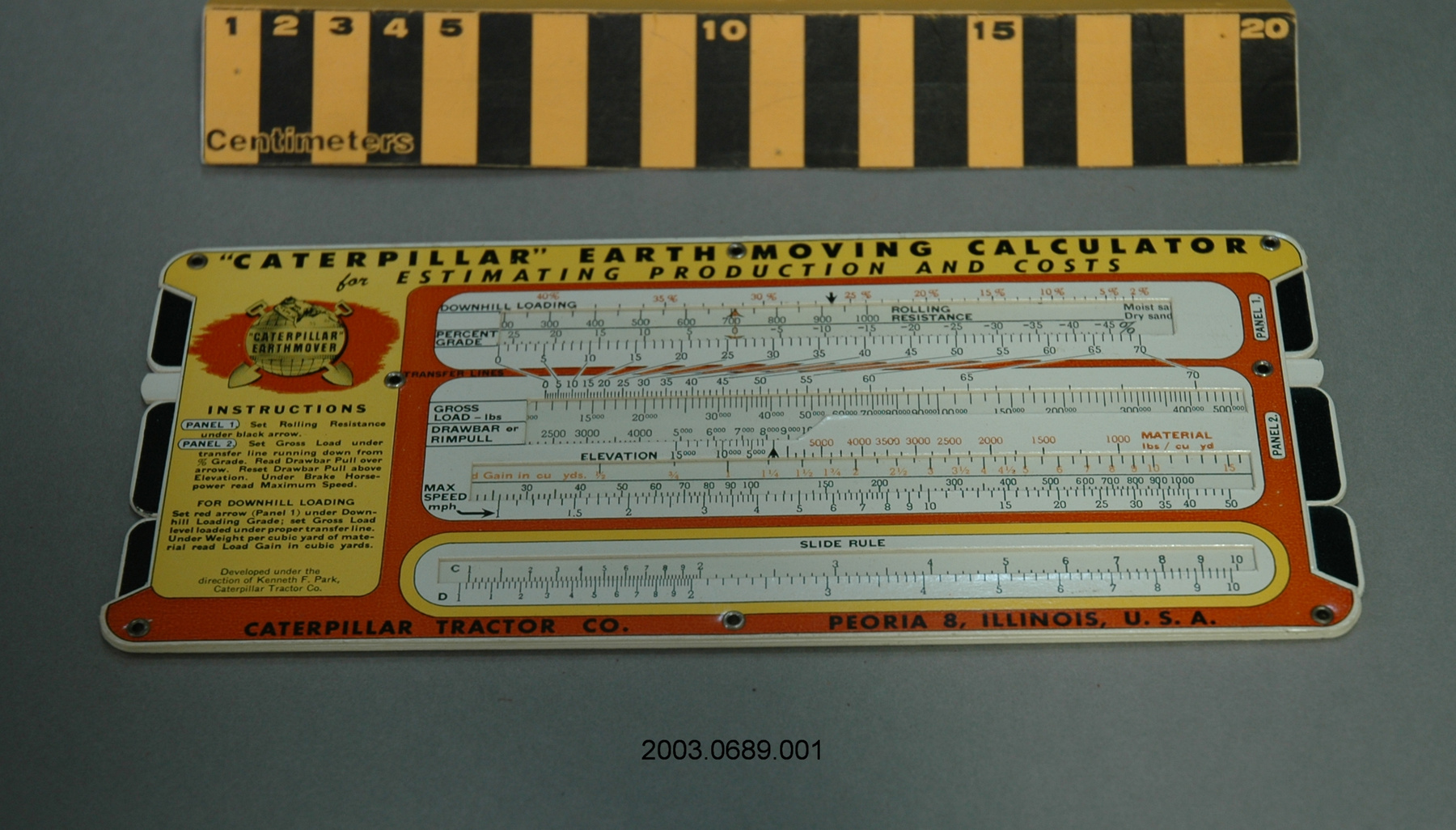

- OBJECT TYPE

- N/A

- DATE

- 2016

- ARTIFACT NUMBER

- 2017.0055.005

- MANUFACTURER

- Unknown

- MODEL

- Unknown

- LOCATION

- Unknown

More Information

General Information

- Serial #

- N/A

- Part Number

- 5

- Total Parts

- 13

- AKA

- N/A

- Patents

- N/A

- General Description

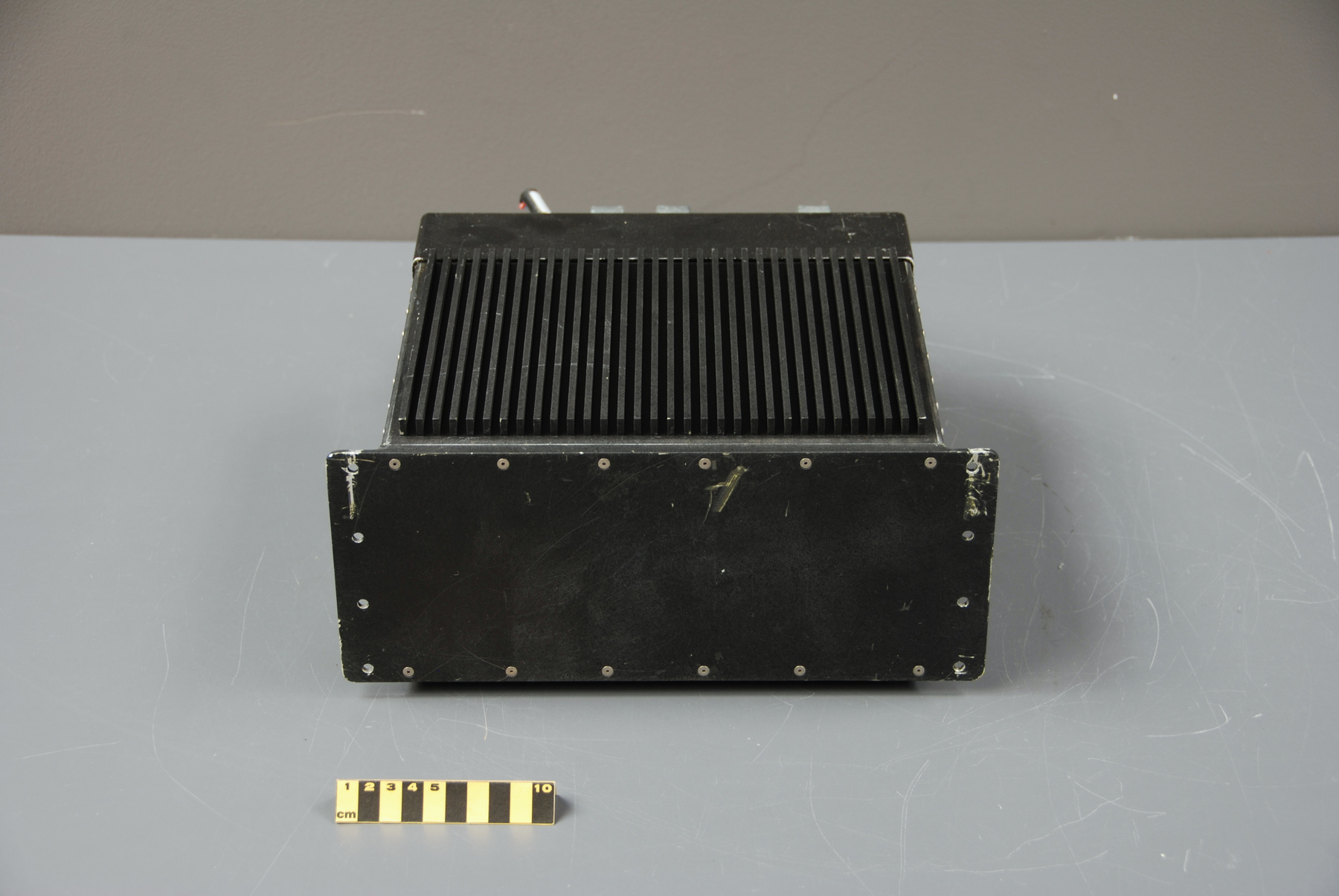

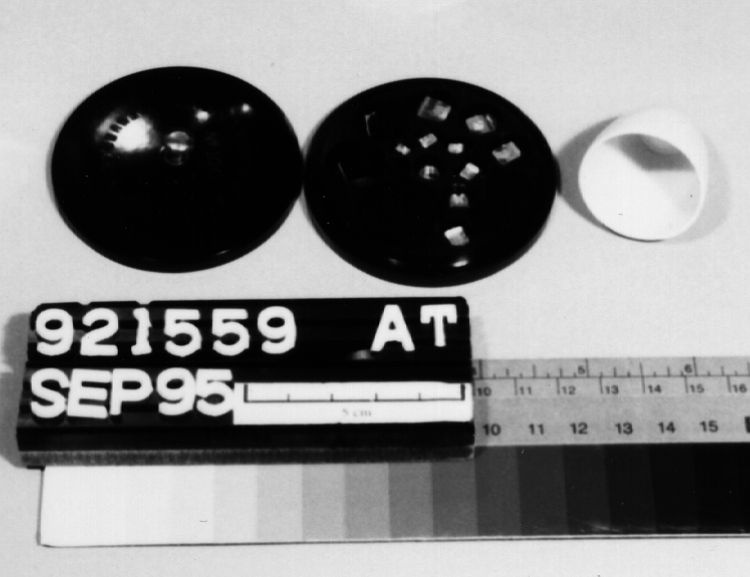

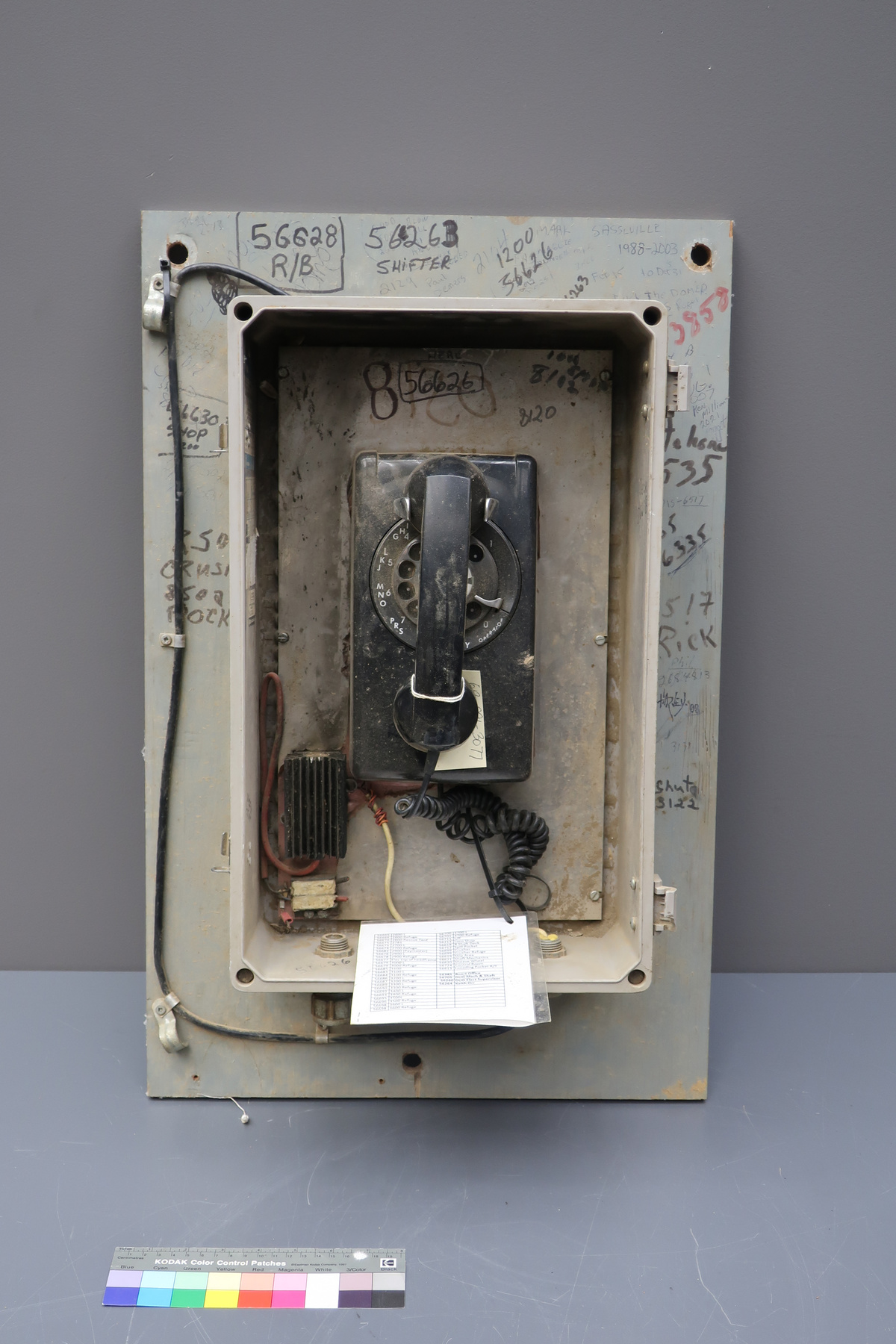

- Predominantly synthetic with metal contacts

Dimensions

Note: These reflect the general size for storage and are not necessarily representative of the object's true dimensions.

- Length

- 17.3 cm

- Width

- 15.7 cm

- Height

- 3.8 cm

- Thickness

- N/A

- Weight

- N/A

- Diameter

- N/A

- Volume

- N/A

Lexicon

- Group

- Mining and Metallurgy

- Category

- Miscellaneous

- Sub-Category

- N/A

Manufacturer

- AKA

- Unknown

- Country

- Unknown

- State/Province

- Unknown

- City

- Unknown

Context

- Country

- Unknown

- State/Province

- Unknown

- Period

- Unknown

- Canada

-

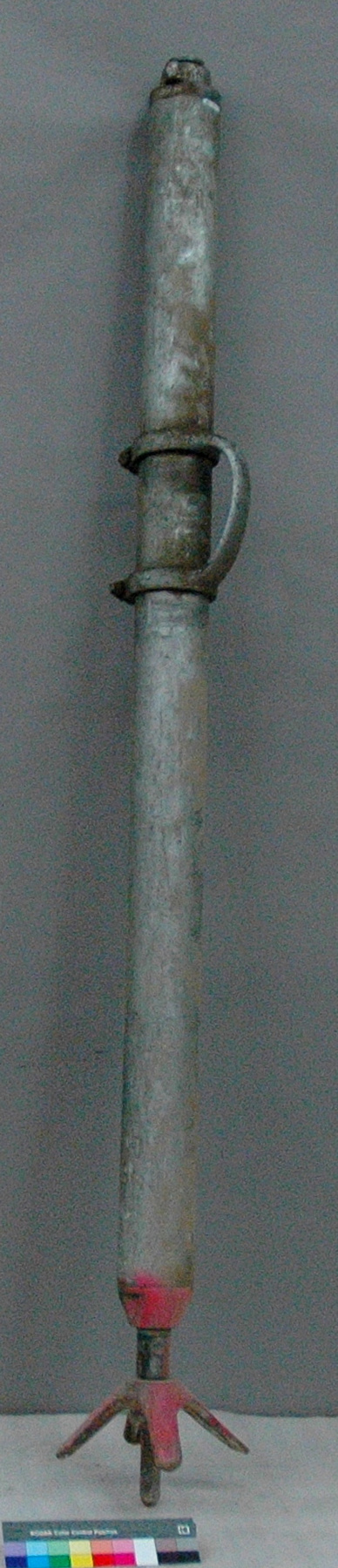

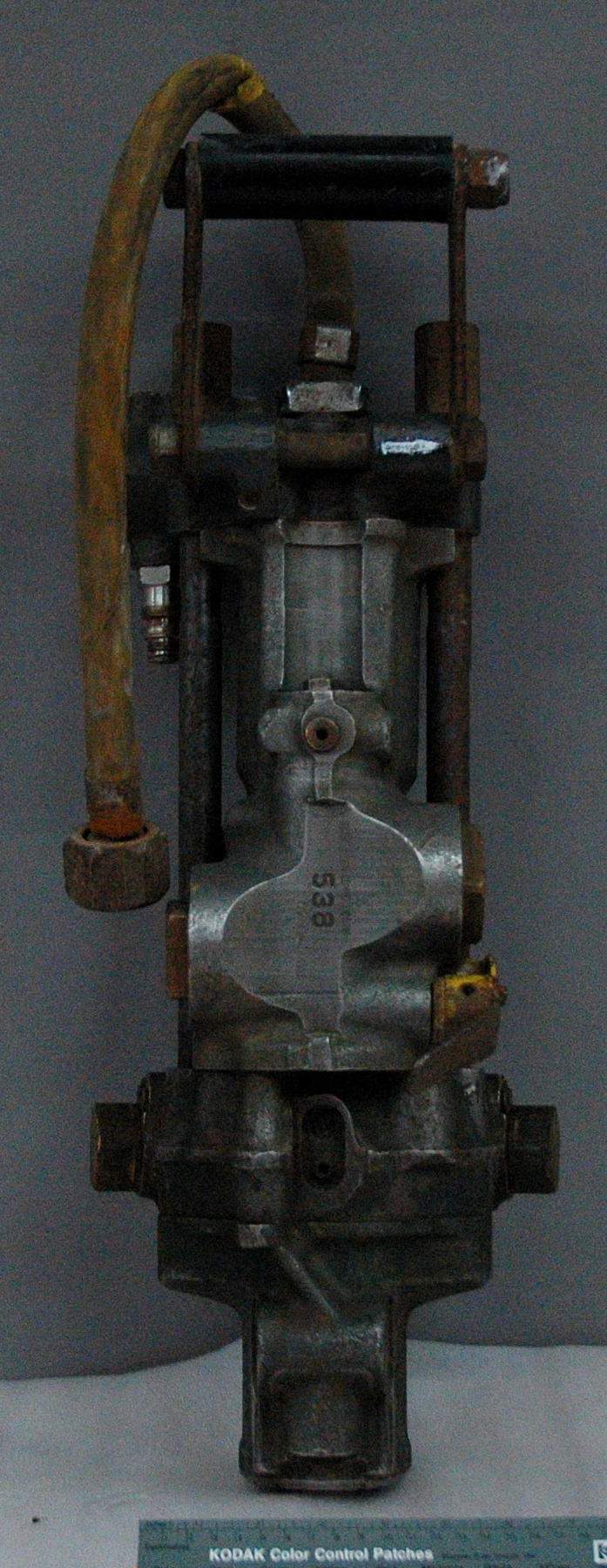

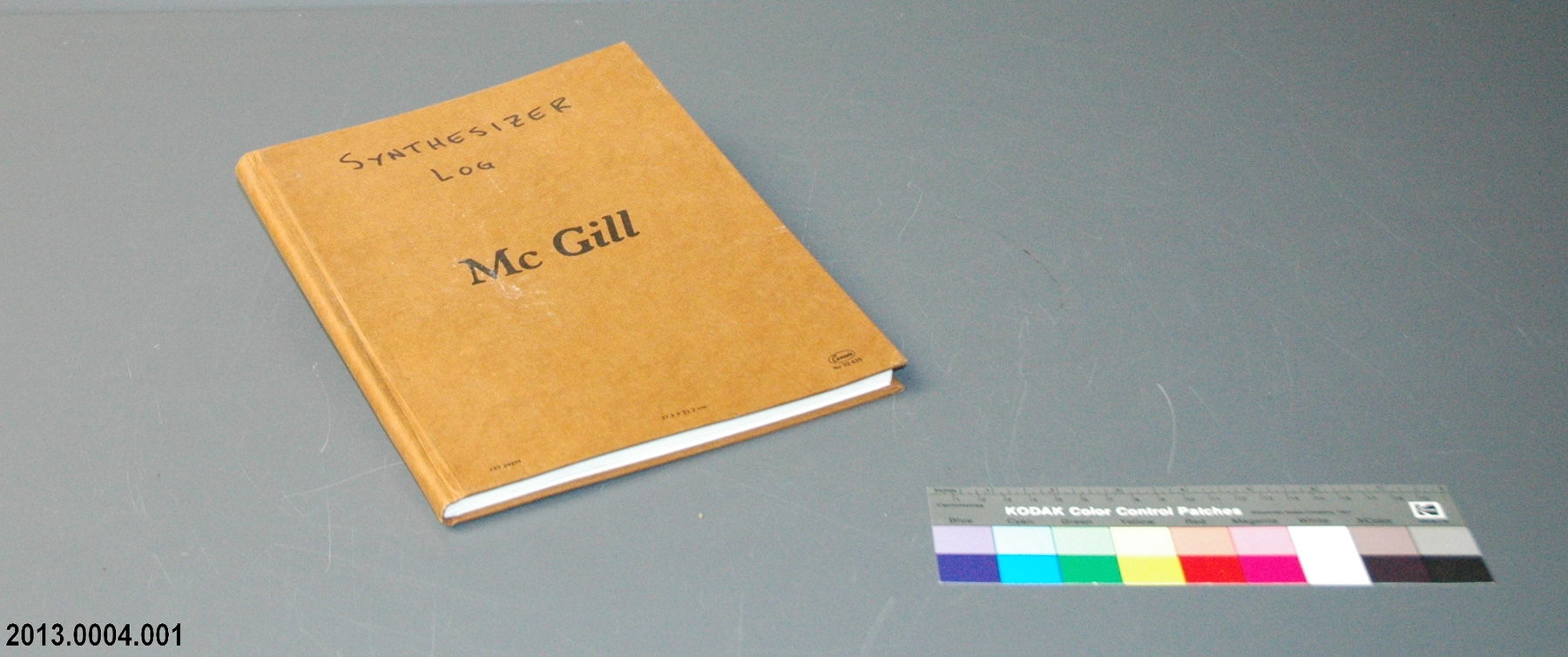

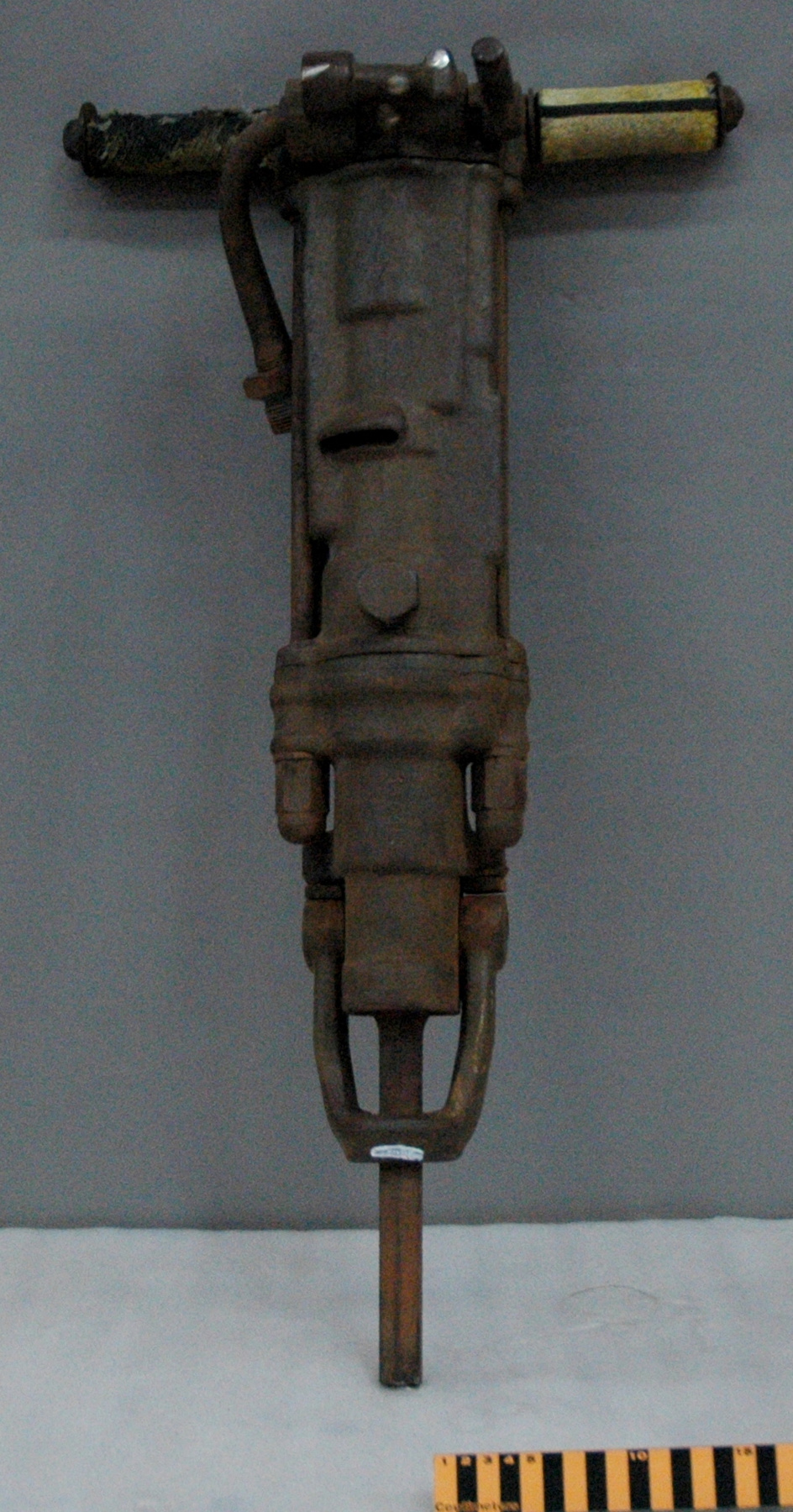

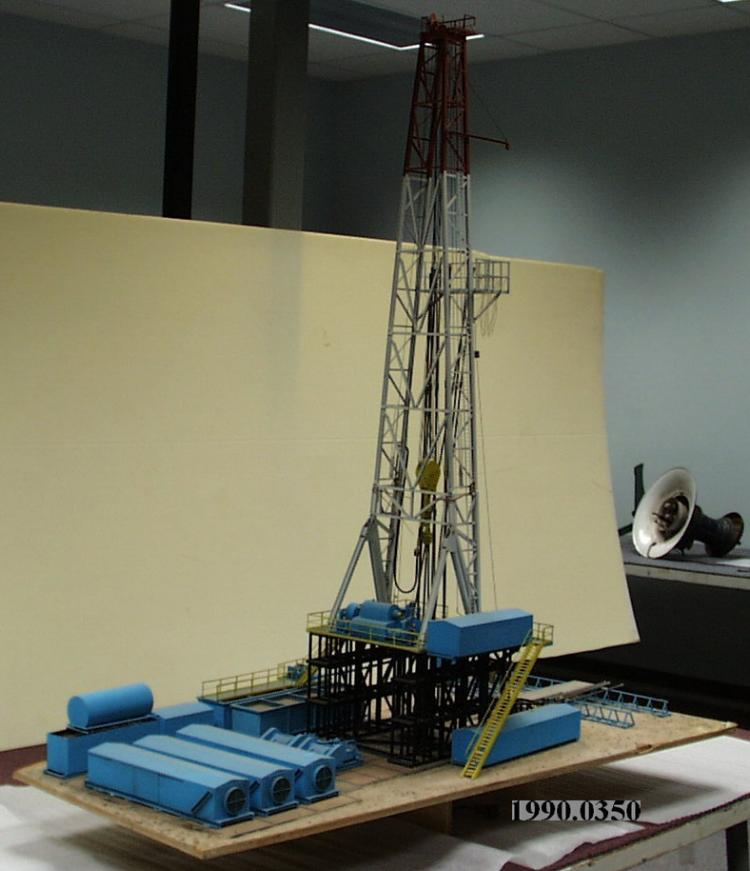

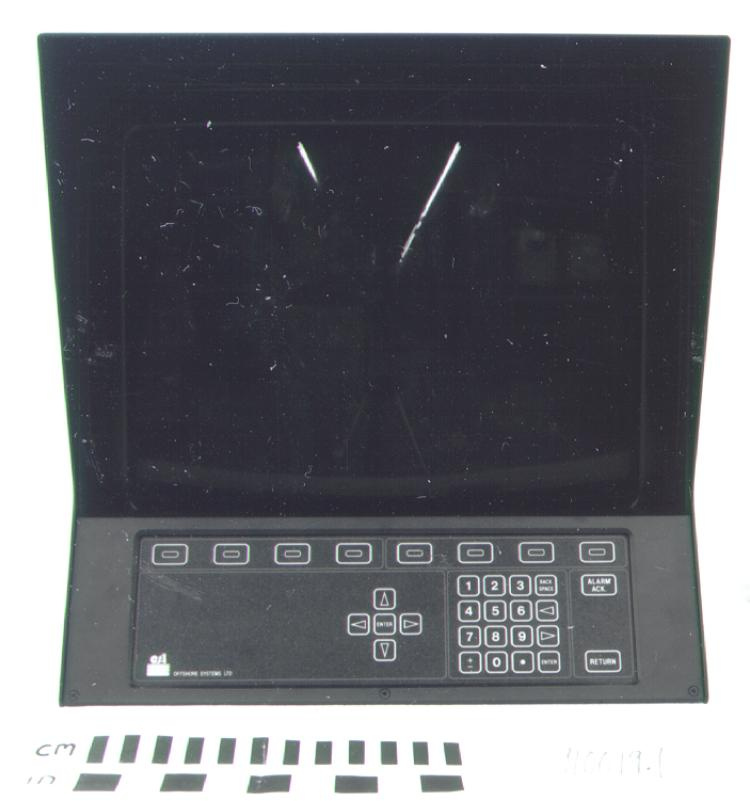

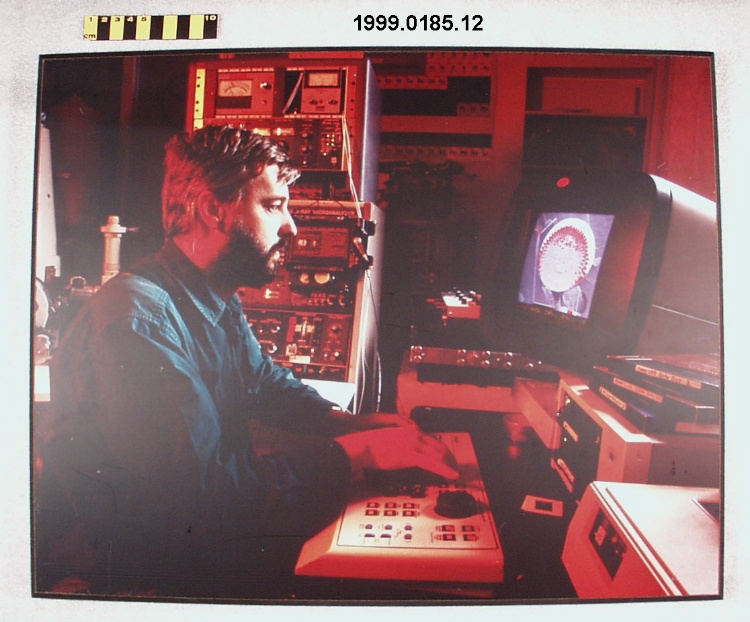

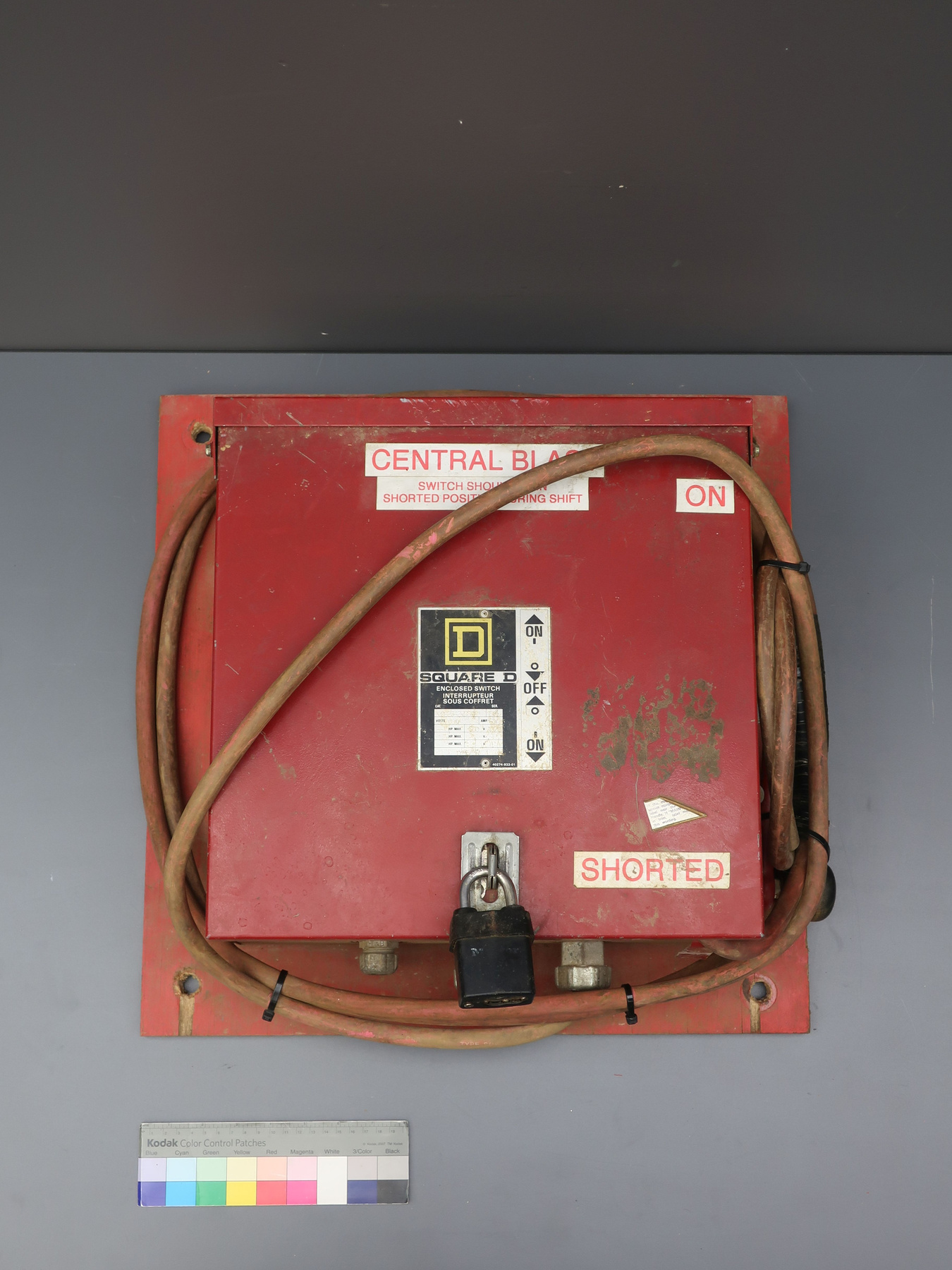

Dr. Jon Peck, who holds a PhD and MSc in Mining Engineering from McGill, is a leading expert in the automation of mobile mining equipment. He is recognized internationally for his work in this field. In 2015, Dr. Peck has been inducted to the International Mining Technology Hall of Fame for his work on automation of surface mining technologies. Dr. Peck’s research on automation dates back to the Canadian Center for Automation and Robotics in Mining. This little documented, but extremely important Centre was created jointly by Ecole Polytechnique and McGill in 1988, and operated at McGill until 1996. The CCARM was led by researchers such as Dr. John Edwards, Dr. Laeeque Daneshmend and Andre Peacher, who continued there the work earlier conducted at the Noranda Research Centre. The Noranda Centre and CCARM were at the core of most of mining R&D, and the entire Canadian automated and remote mining community has its roots in these institutions. When CCARM lost its funding, Dr. Peck moved to Queen’s University, where he served as the Head of the Department of Mining Engineering. In this position, he not only developed new technologies but also supervised PhD research of a younger generation of mining engineers, who are today responsible for designing technologies for mining from deep sea to space. In 1992, Dr. Peck founded Aquila Mining Systems Ltd. which designed an Advanced Monitoring and Positioning Platform. The product was sold to Caterpillar in 1996 and is now a standard platform in surface mining operations. At Aquila, Dr. Peck was responsible for pioneering of the real-time high precision GOS guidance for blasthole drills and cable shovels and drill monitoring with rock recognition capabilities. In fact, all subsequent work on rock recognition has been based on Dr. Peck’s research. In 2004, Dr. Peck created Peck Tech, where he continues to work on augmented GPS devices, advanced rock recognition algorithms, and autonomous drill operations. He also advices mining companies around the world on automation and remote mining. Dr. Peck continues to educate and mentor a new generation of Canadian mining engineers through his work at Queen’s, McGill and Concordia. Dr. Sandy Pyke is an Electronic Technologist, software engineer and hardware architect. He worked with Dr. Peck at Aquila in the 1990s, and then continued developing the monitoring and positioning platforms at Caterpillar. He built prototypes of Aquila’s and Peck Tech’s technologies. Dr. Pyke rejoined Peck at Peck Tech in 2004. (From Acquisition Proposal, see Ref. 1) - Function

-

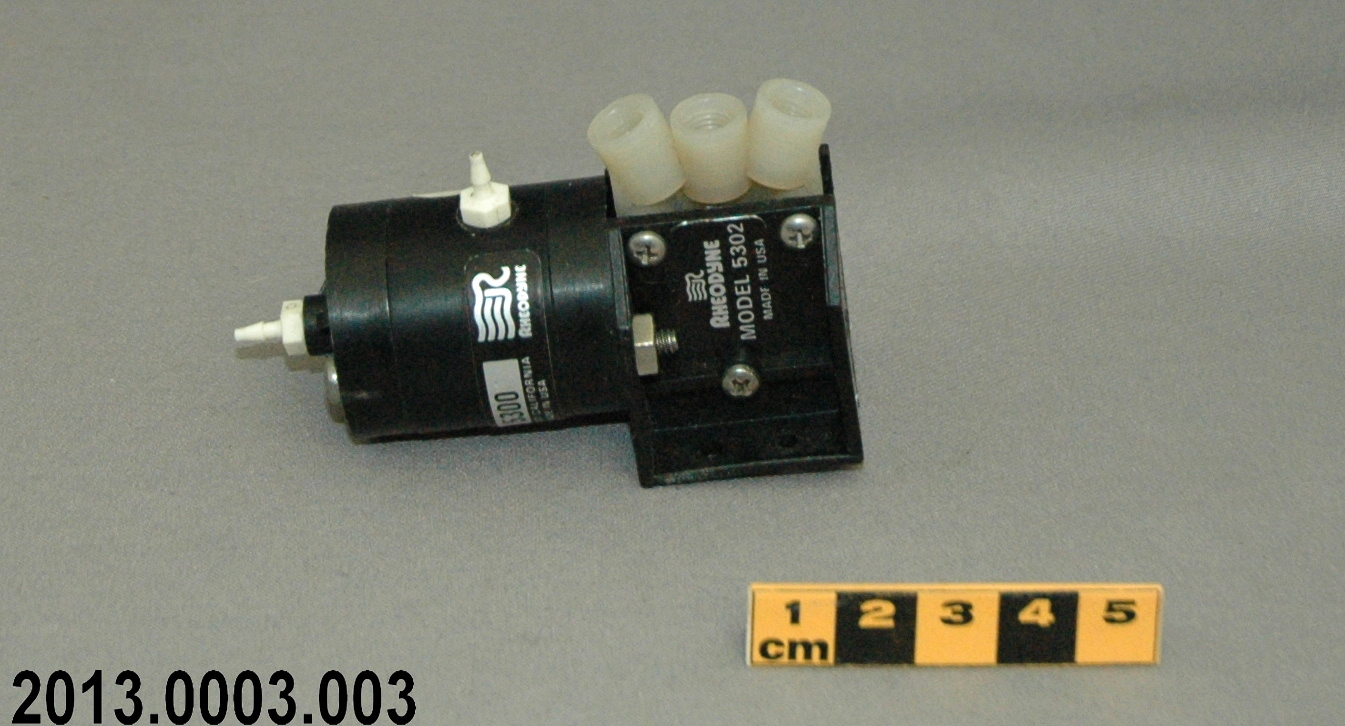

To connect the scanner to another unit for transfer of information. - Technical

-

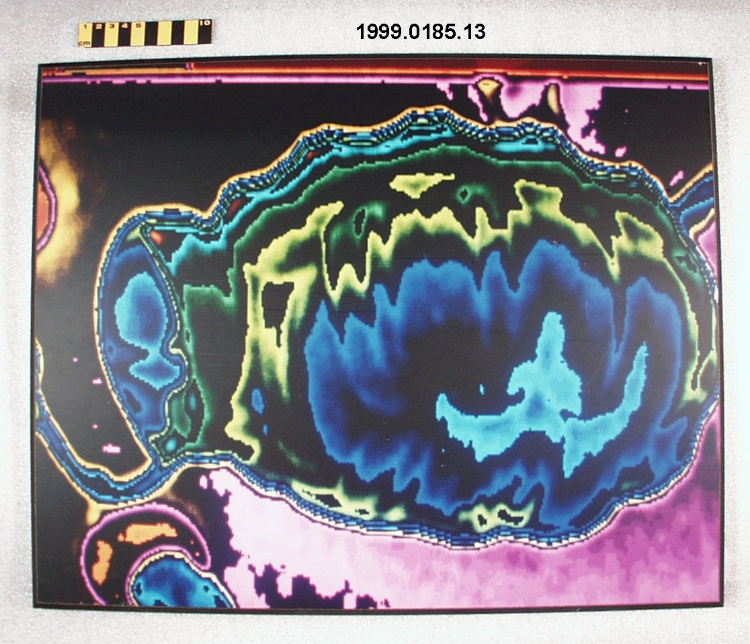

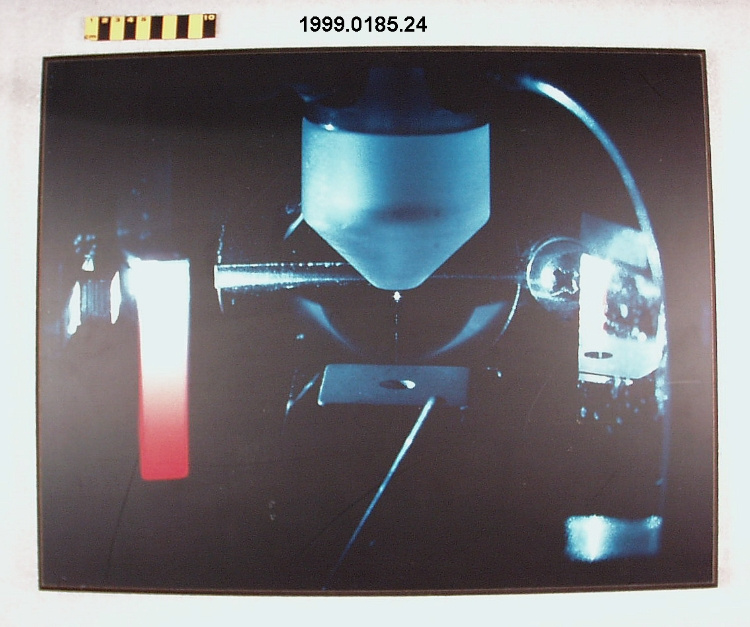

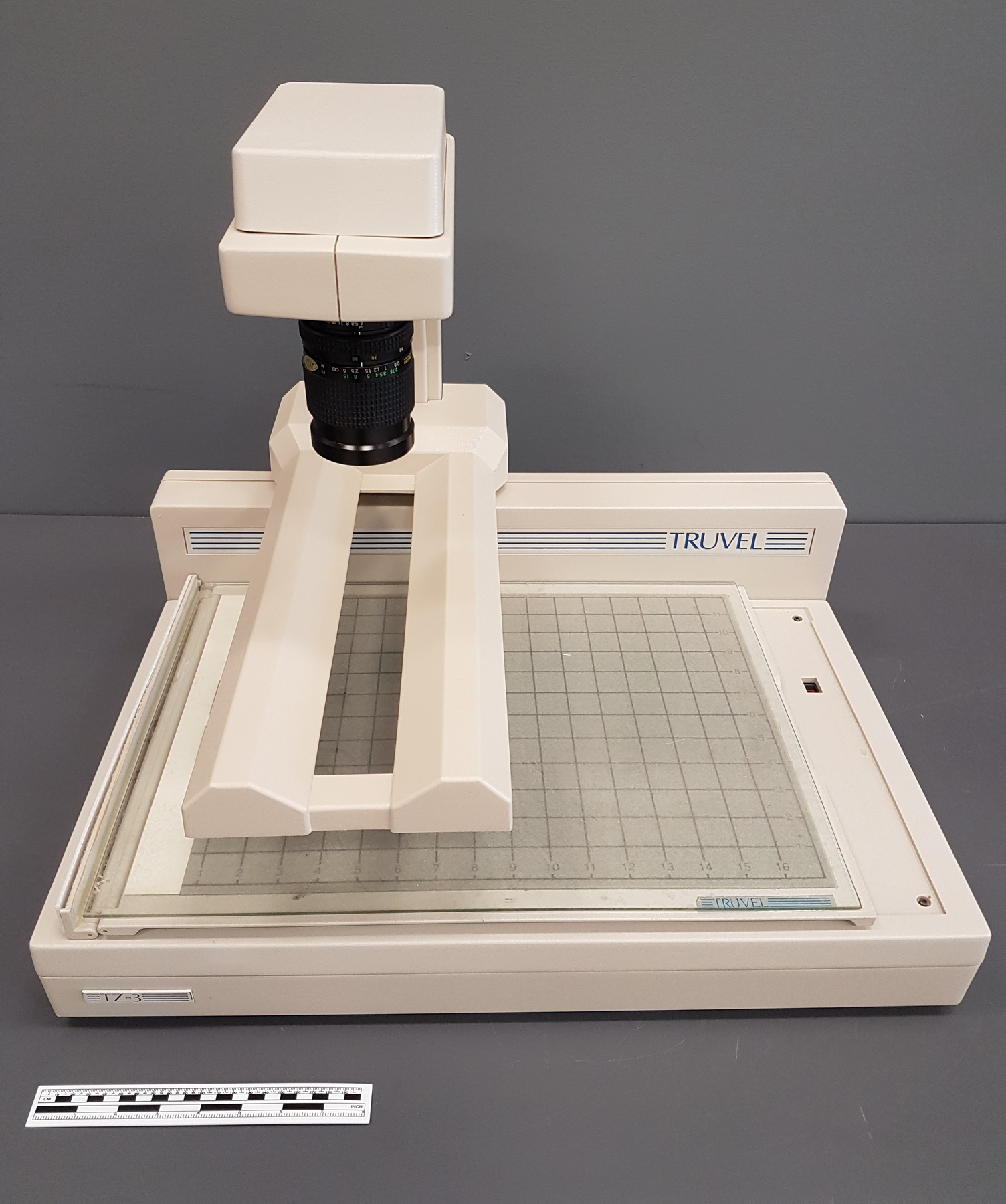

The uGPS Rapid Mapper is a small, portable, fully automated, remotely controlled scanner. The scanner is furnished with a GPS system, which can map reference points for an underground mine and use the points to positions the scanner in the mine allowing it to accurately locate it. uGPS Rapid Mapper is a unique laser-based, mobile mapping technology designed to survey underground mines and build 3D maps that can be converted to virtual mines or can be modeled on a PC. The system travels through a mine and scans it very quickly, creating a 3D point cloud data. The data conveys very detailed information on the mine. It allows us to examine the mine inside, but also to step out of the mine and see its model. This extends the applications of the technology from mine planning and safety to assessment of geological data and vertical excavations for narrow-veined deposits. The technology includes 2 laser scanners, which scan the area creating point clouds; an inertial sensor that calculates position, orientation and velocity of the unit underground; an onboard computer, optional Wi-Fi connectivity, and an RFID tag reader. This allows for an open loop scanning, close loop scanning and vertical scanning. (From Acquisition Proposal, see Ref. 1) - Area Notes

-

Unknown

Details

- Markings

- Moulded into the larger connector's casing: "SOURIAU/ TRIM TRIO/ [clockwise on the end of the connector] A/ B/ C/ D/ E/ F/ G/ H"

- Missing

- Appears complete

- Finish

- Predominantly black cord and connectors with one clear synthetic end showing red, white, green and blue wires inside.

- Decoration

- N/A

CITE THIS OBJECT

If you choose to share our information about this collection object, please cite:

Unknown Manufacturer, Cable, circa 2016, Artifact no. 2017.0055, Ingenium – Canada’s Museums of Science and Innovation, http://collections.ingeniumcanada.org/en/item/2017.0055.005/

FEEDBACK

Submit a question or comment about this artifact.

More Like This