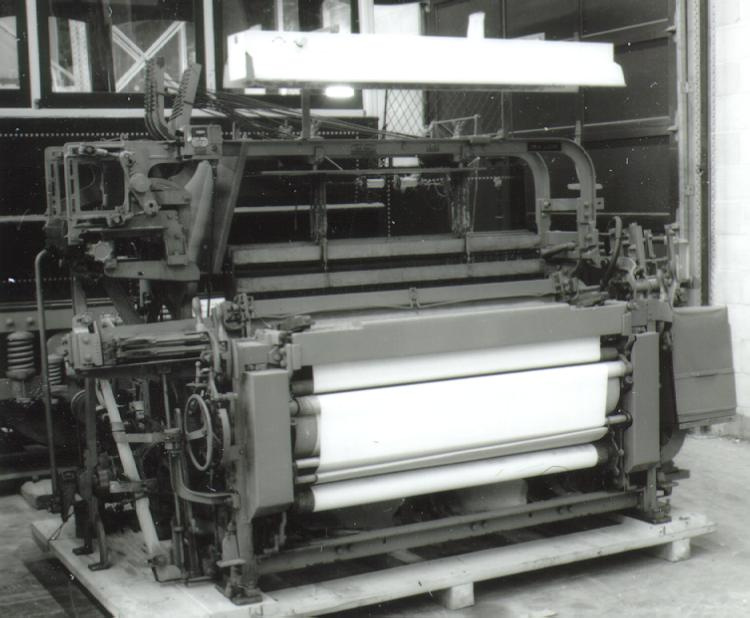

Métier à tisser

Utiliser cette image

Puis-je réutiliser cette image sans autorisation? Oui

Les images sur le portail de la collection d’Ingenium ont la licence Creative Commons suivante :

Copyright Ingenium / CC BY-NC-ND (Attribution-NonCommercial 4.0 International (CC BY-NC 4.0)

ATTRIBUER CETTE IMAGE

Ingenium,

1987.2059.001

Permalien:

Ingenium diffuse cette image sous le cadre de licence Creative Commons et encourage son téléchargement et sa réutilisation à des fins non commerciales. Veuillez mentionner Ingenium et citer le numéro de l’artefact.

TÉLÉCHARGER L’IMAGEACHETER CETTE IMAGE

Cette image peut être utilisée gratuitement pour des fins non commerciales.

Pour un usage commercial, veuillez consulter nos frais de reproduction et communiquer avec nous pour acheter l’image.

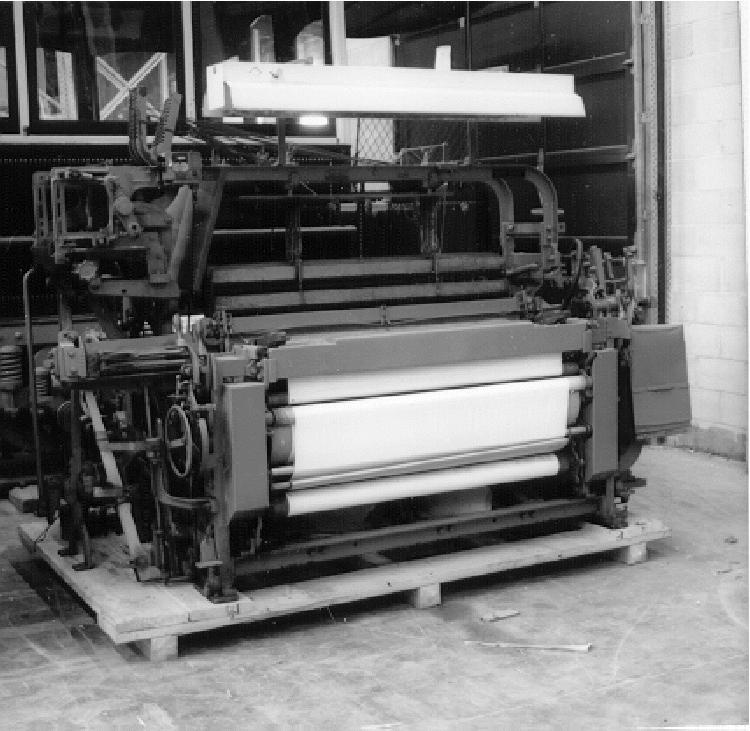

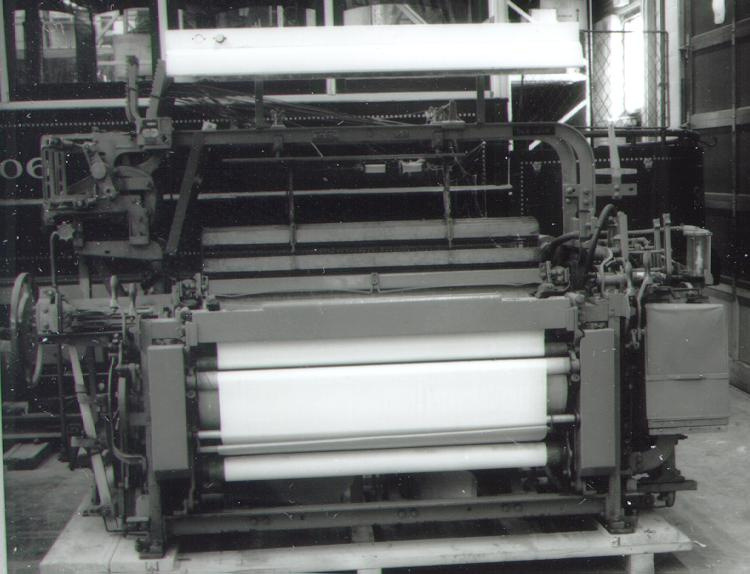

- TYPE D’OBJET

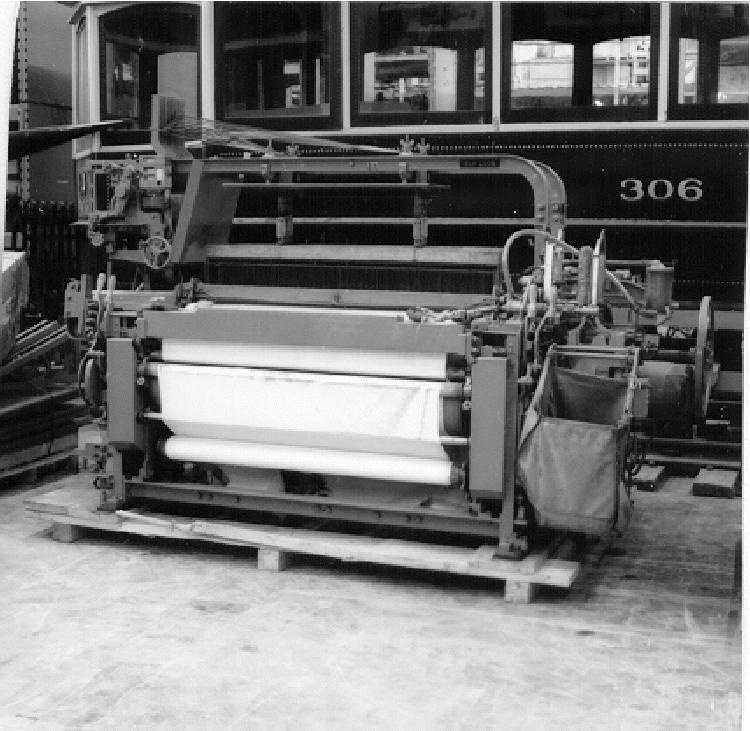

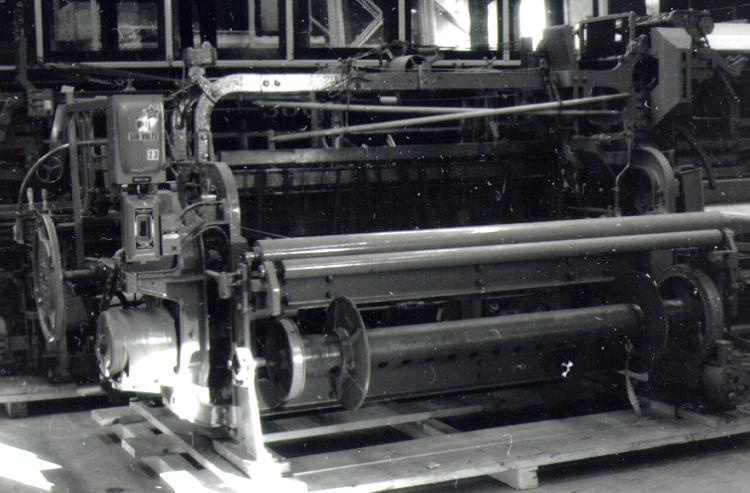

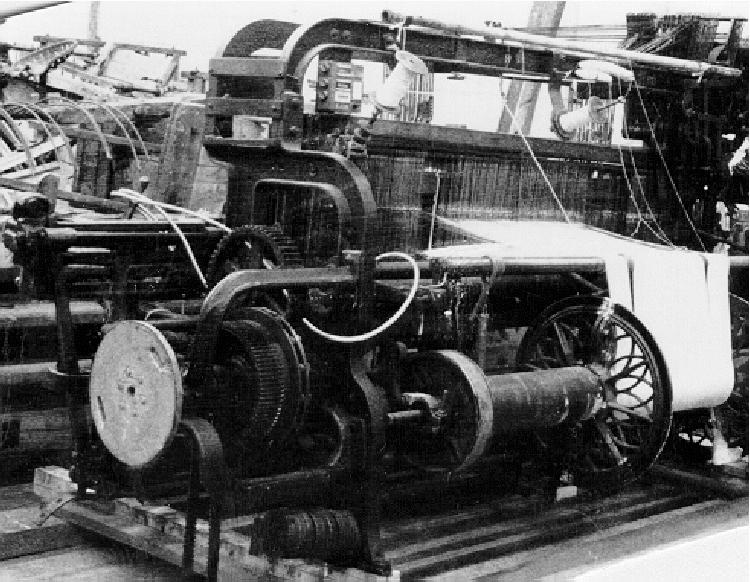

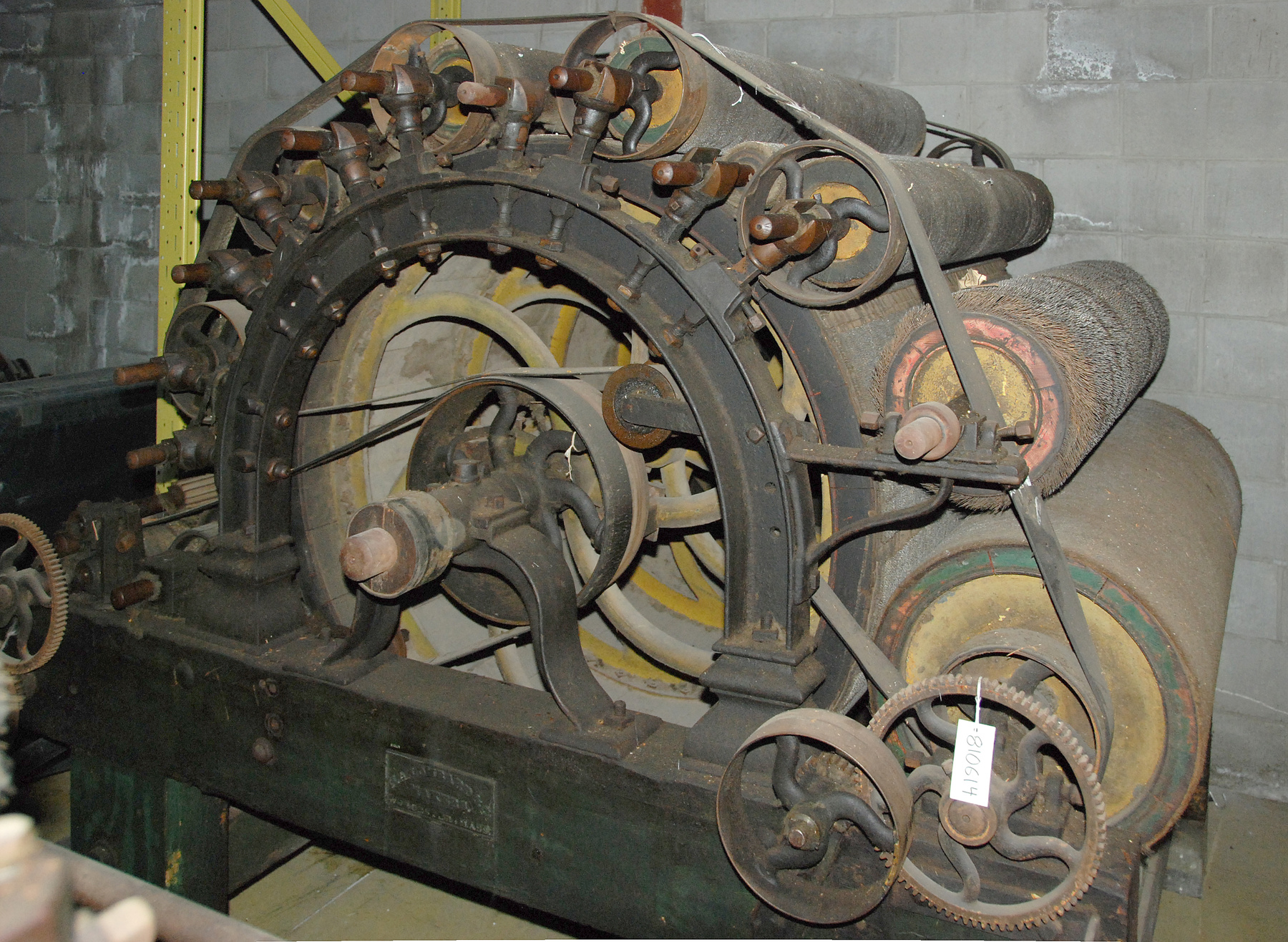

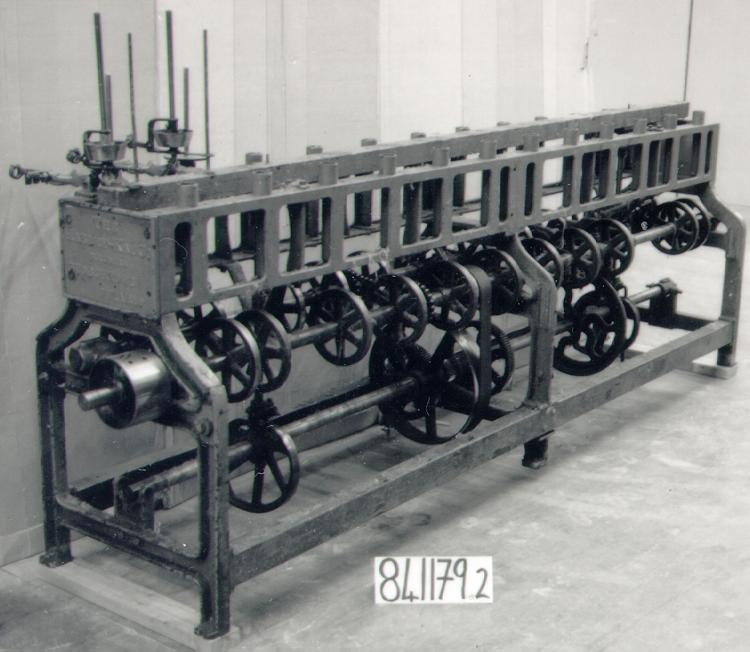

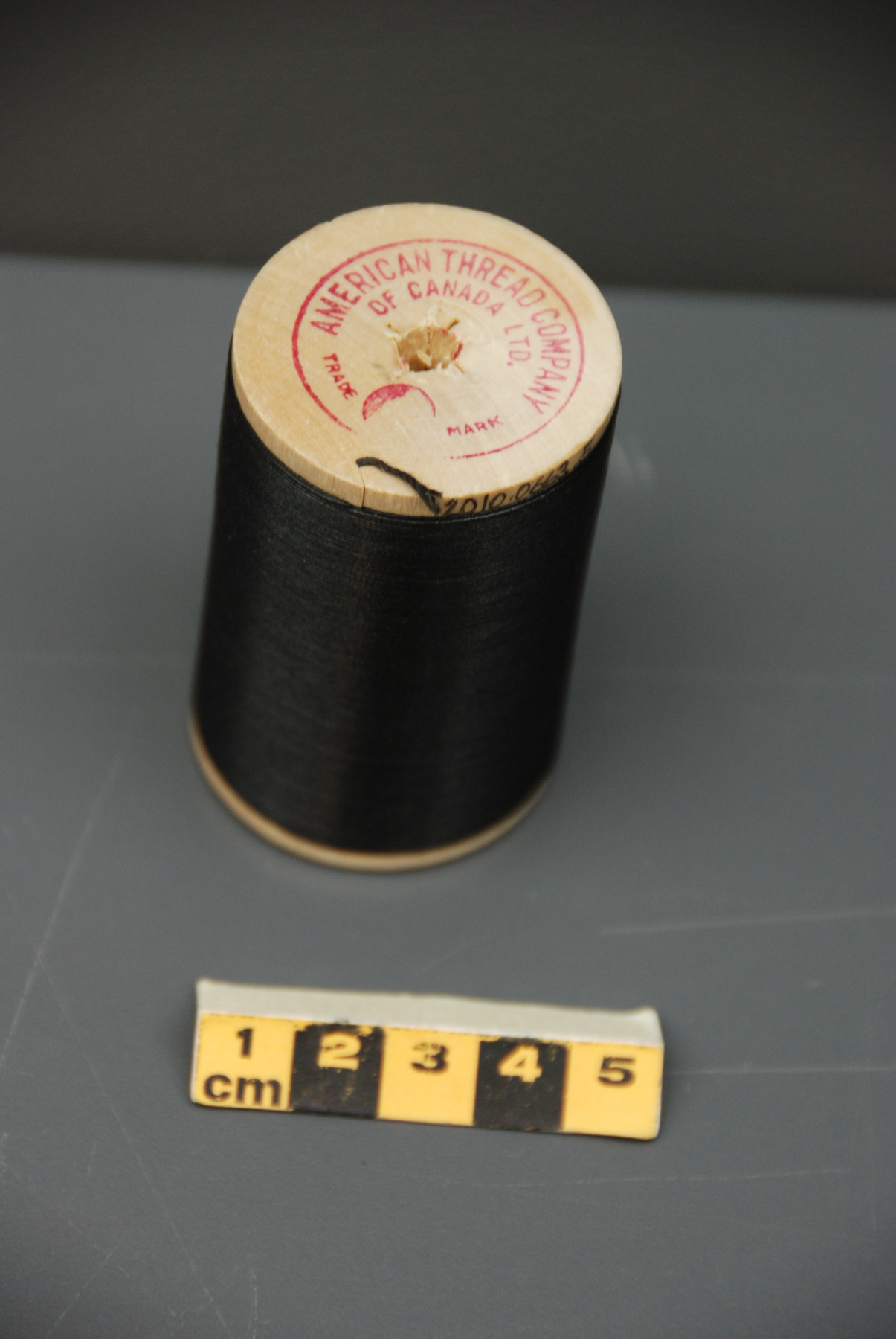

- POWER/20 HARNESS/SILK

- DATE

- 1941–1957

- NUMÉRO DE L’ARTEFACT

- 1987.2059.001

- FABRICANT

- Crompton & Knowles Loom Works

- MODÈLE

- S-5

- EMPLACEMENT

- Worcester, Massachusetts, United States of America

Plus d’information

Renseignements généraux

- Nº de série

- S/O

- Nº de partie

- 1

- Nombre total de parties

- 7

- Ou

- S/O

- Brevets

- S/O

- Description générale

- METAL WITH WOOD, LEATHER, SYNTHETIC, FUR LINING IN SHUTTLES, RUBBER, FIBRE (SYNTHETIC) SET UP AS WORK IN PROGRESS ON LOOM

Dimensions

Remarque : Cette information reflète la taille générale pour l’entreposage et ne représente pas nécessairement les véritables dimensions de l’objet.

- Longueur

- 275,0 cm

- Largeur

- 173,0 cm

- Hauteur

- 202,0 cm

- Épaisseur

- S/O

- Poids

- S/O

- Diamètre

- S/O

- Volume

- S/O

Lexique

- Groupe

- Technologie industrielle

- Catégorie

- Appareils industriels

- Sous-catégorie

- S/O

Fabricant

- Ou

- Crompton Knowles

- Pays

- United States of America

- État/province

- Massachusetts

- Ville

- Worcester

Contexte

- Pays

- Inconnu

- État/province

- Inconnu

- Période

- THIS LOOM WAS IN USE BY 1957 & STILL IN USE UP TO AT LEAST 1981

- Canada

-

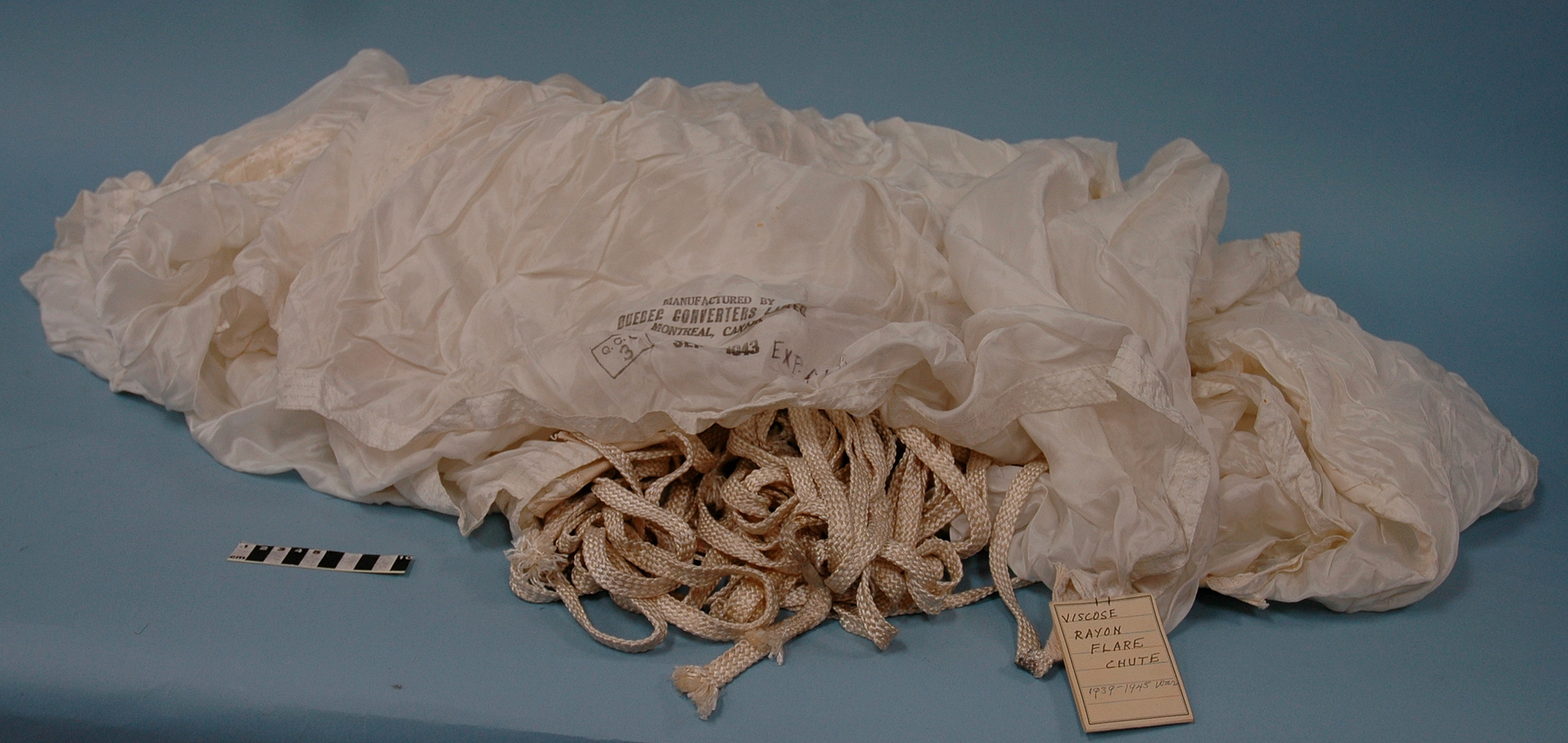

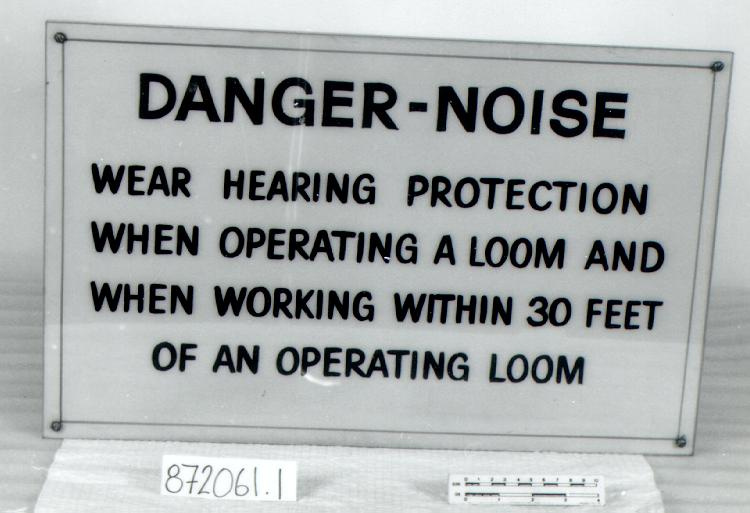

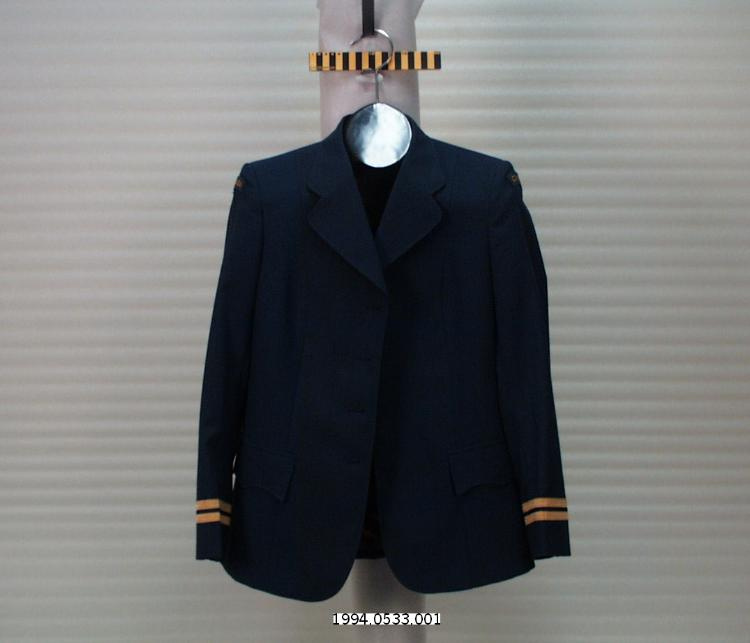

Textile manufacturing has been an important industry in Canada since the mid-nineteenth century. Since its early days, the textile industry was mainly based in what is now Ontario and Quebec. Early European settlers produced home spun textiles (from hemp, and later wool or linen-wool blends), but textiles were also imported. (A. B. McCullough, The Primary Textile Industry in Canada: History and Heritage, Ottawa: National Historic Sites, Parks Service, 1992, p45) By the early 19th century, elements of the textile industry had moved from outside the home, into factories (McCullough p46). The earliest factories worked with wool. Cotton (never used substantially in home production because cotton cannot be grown in Canada) factories were first established in Lower Canada in the 1840s (McCullough p52). By the beginning of the twentieth century, the textile industry was well established in Canada. Canada started importing synthetic fabrics in the early twentieth century, but did not start manufacturing them until after 1924 (McCullough p10). The synthetic sector grew throughout the mid-twentieth century and continued to expand after the Second World War, in part at the expense of the natural fibre sector (McCullough p145; Douglas Hallam, The Textile Industry, p272-273). Synthetic textiles became increasingly popular after the war due to a combination of factors: post war shortages and a population boom created a greater demand for fabric than natural textile production could meet; North American companies wanted independence from European suppliers; industries towards independence from the European producers such as English woolens and French silk finery; and a successful series of advertisement campaigns that promoted artificial fabrics as the “choice” garments of modern men and women (Susannah Handley, Nylon, 25-53). Although the textile industry always relied heavily on imported raw materials (wool from England and Australia, cotton from the United States, and petrochemical compounds for synthetic fibres from the United States and Japan ), at its peak in the mid twentieth century it not only filled more than half of the demand of the domestic market, but also managed to meet the requirements of the military (Hallam 273, 277). In the 1960s and 1970s, the international market pushed the industry to rationalize. In most cases, only major firms survived (McCullough 147). The textile industry was an important Canadian employer. According to A. B. McCullough, of the Canadians working in manufacturing in 1880, 13% worked in the clothing industry and 5% produced textiles (p9). The industry supplied crucial industrial employment in the difficult years of 1930-1935. Throughout the twentieth-century, there were a number of periods of labour unrest, which variously focused on working hours, safety, and wages. By the 1970s, Canadian textile workers earned the highest pay in the sector across the globe (McCullough 95-114). This loom was used in DuPont Canada’s Kingston mill, which manufactured synthetic textiles. Its parent company, E. I. du Pont de Nemours, created by Elenthere Irenee DuPont in 1802, originally specialized in the production of black explosive powder, which it supplied to the American military and which also was used in frontier exploration/expansion (Handley 13-14). DuPont continued to develop and produce explosives throughout the nineteenth century (14-15). In 1902, DuPont began to expand and greatly diversify its output with plants manufacturing various chemical components, varnishes, and dyes (Handley 24). Additionally, it contributed to the evolution of modern chemical engineering and enriched the rapidly growing faculty of chemical engineering in MIT (Pap Ndiave, Nylong and Bombs, p57). DuPont has been influential in textiles since the mid-twentieth century. Much of the company’s success was due to its work with synthetic fibres. DuPont engineered a large portion of the synthetic fabrics of the twentieth century, the best-known being nylon. Nylon revolutionized the manufacturing of stockings, eliminating the need for silk. As of 2019, a small subsiduary of DuPont still deals with innovative textiles such as nylon, Kevlar, and Tyvek. DuPont had had investments in Canada for sometime, and in 1954, the company created DuPont Canada Limited. DuPont Canada played a big role in the textile industry. In 1960s and 1970s, DuPont Canada was the leader in sales and second in employment in the sector (Richard paul Olsen, The Textile Industry) . The DuPont research and development facility in Kingston, Ontario had a multimillion dollar budget and contributed to the advancements in the field of chemical engineering (Julia McKay, Quality People Fiber). - Fonction

-

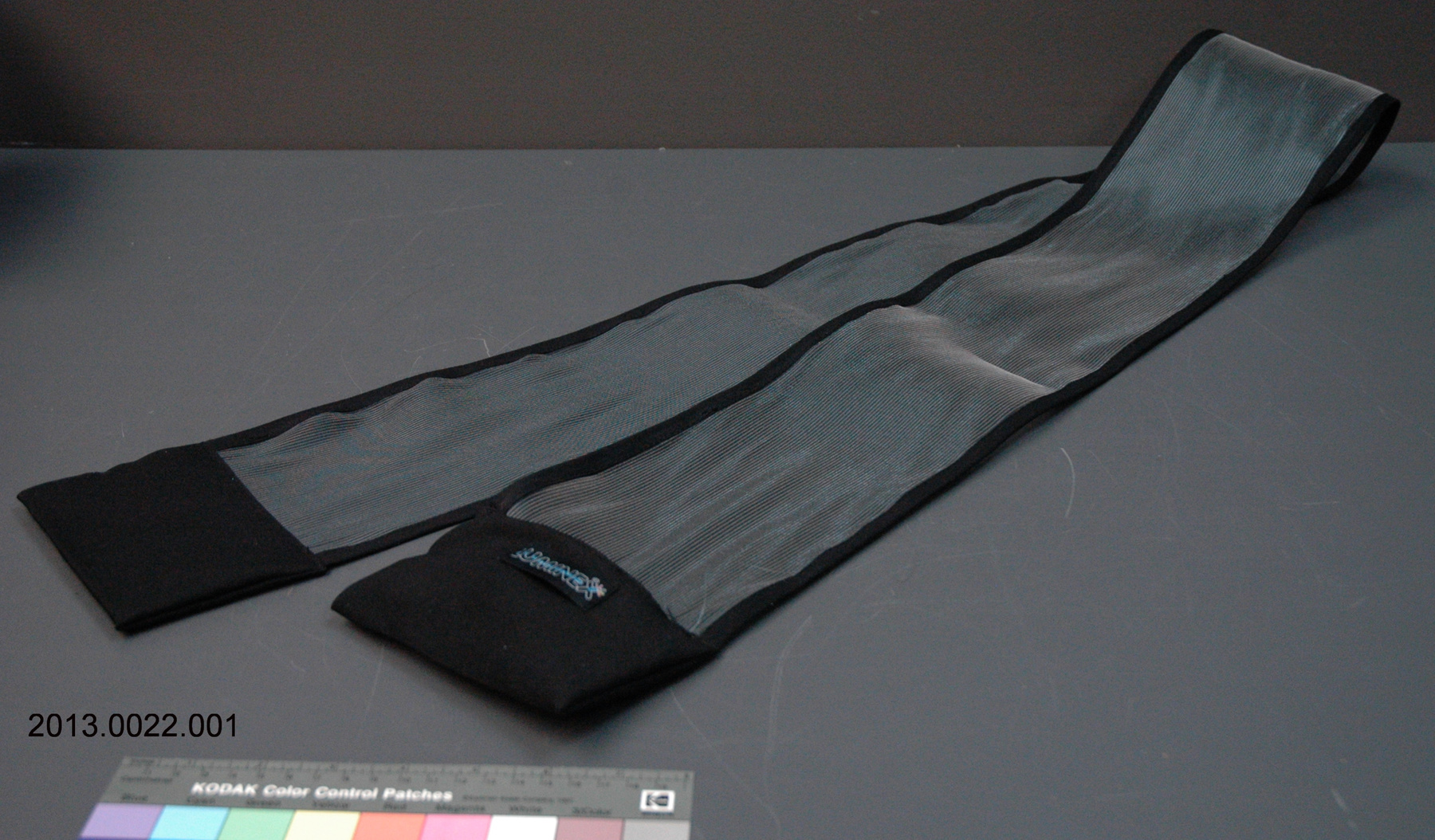

TO AUTOMATICALLY WEAVE FIBRE INTO CLOTH - Technique

-

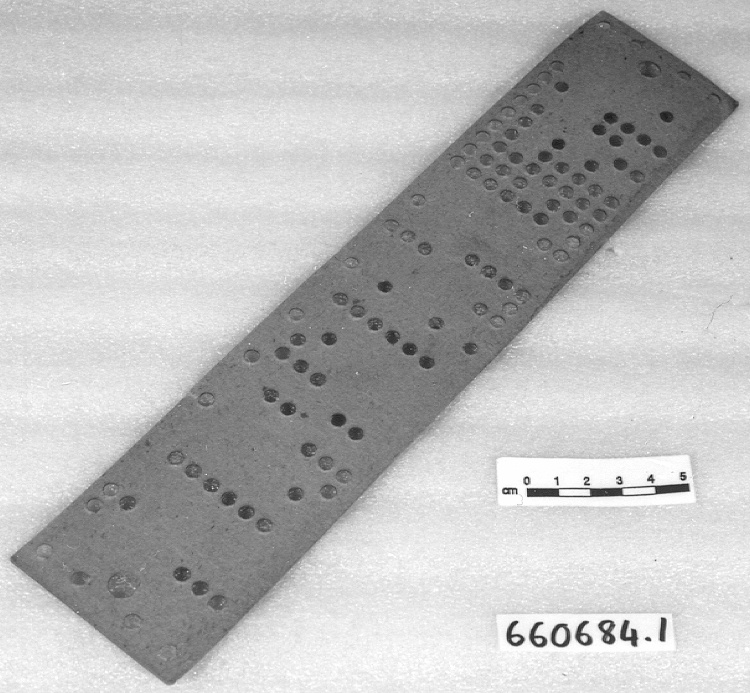

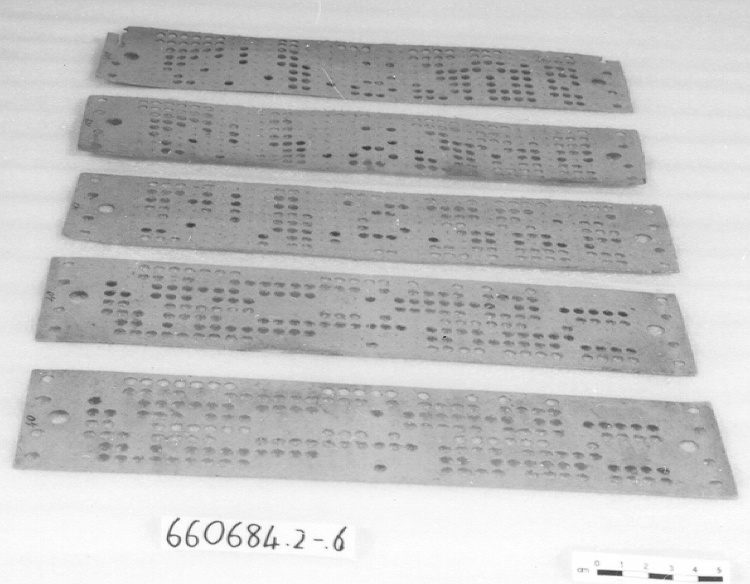

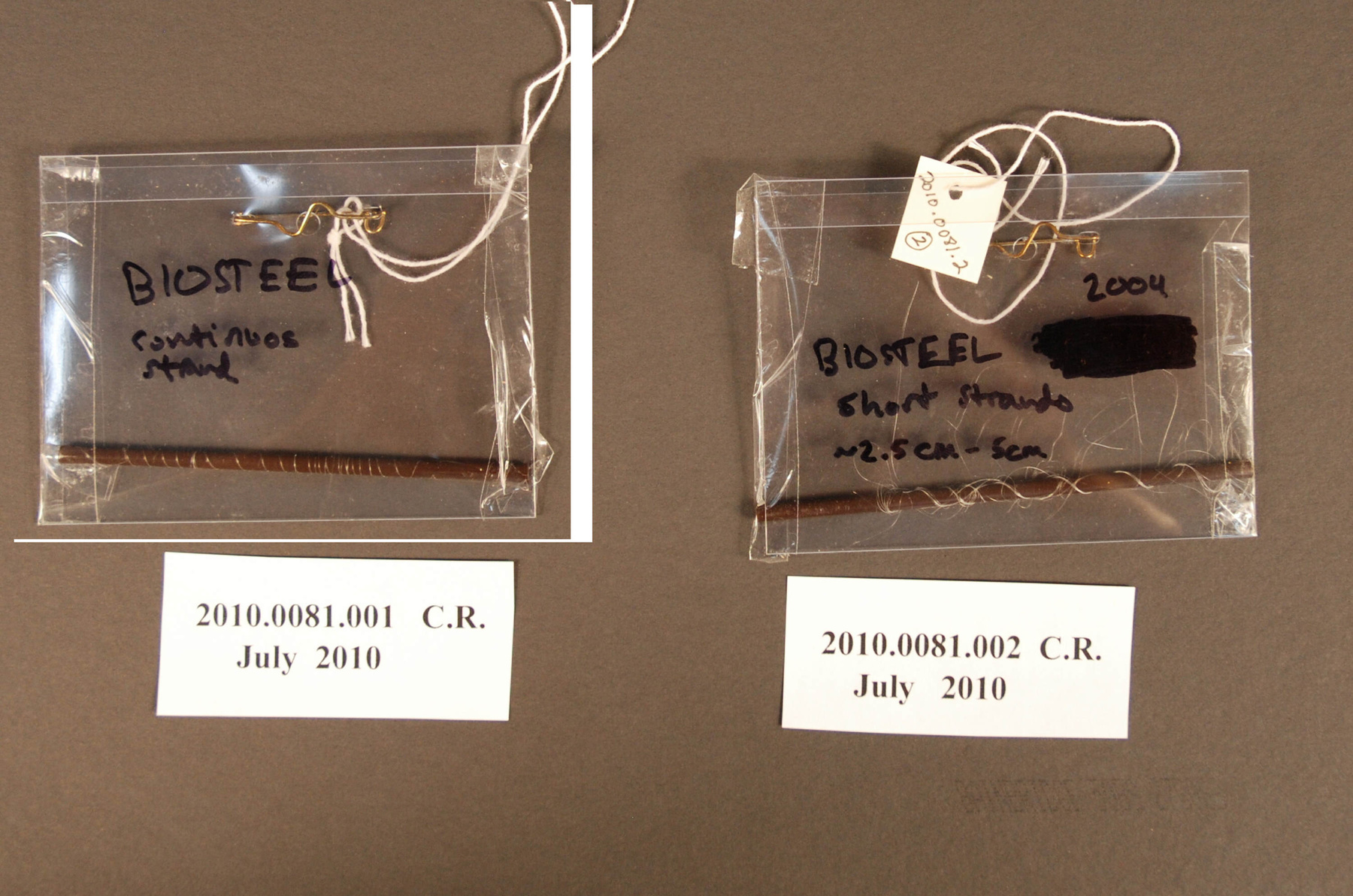

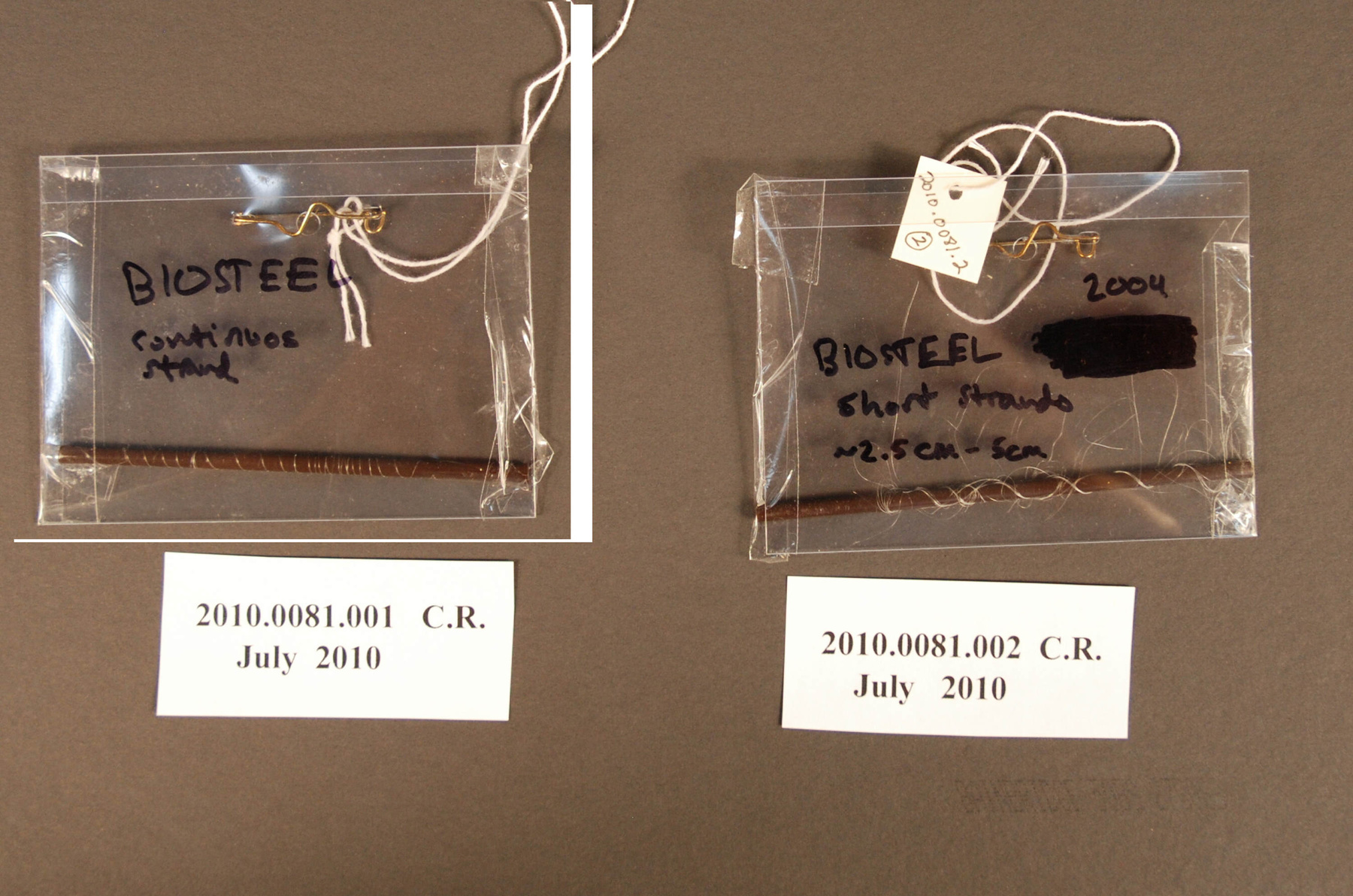

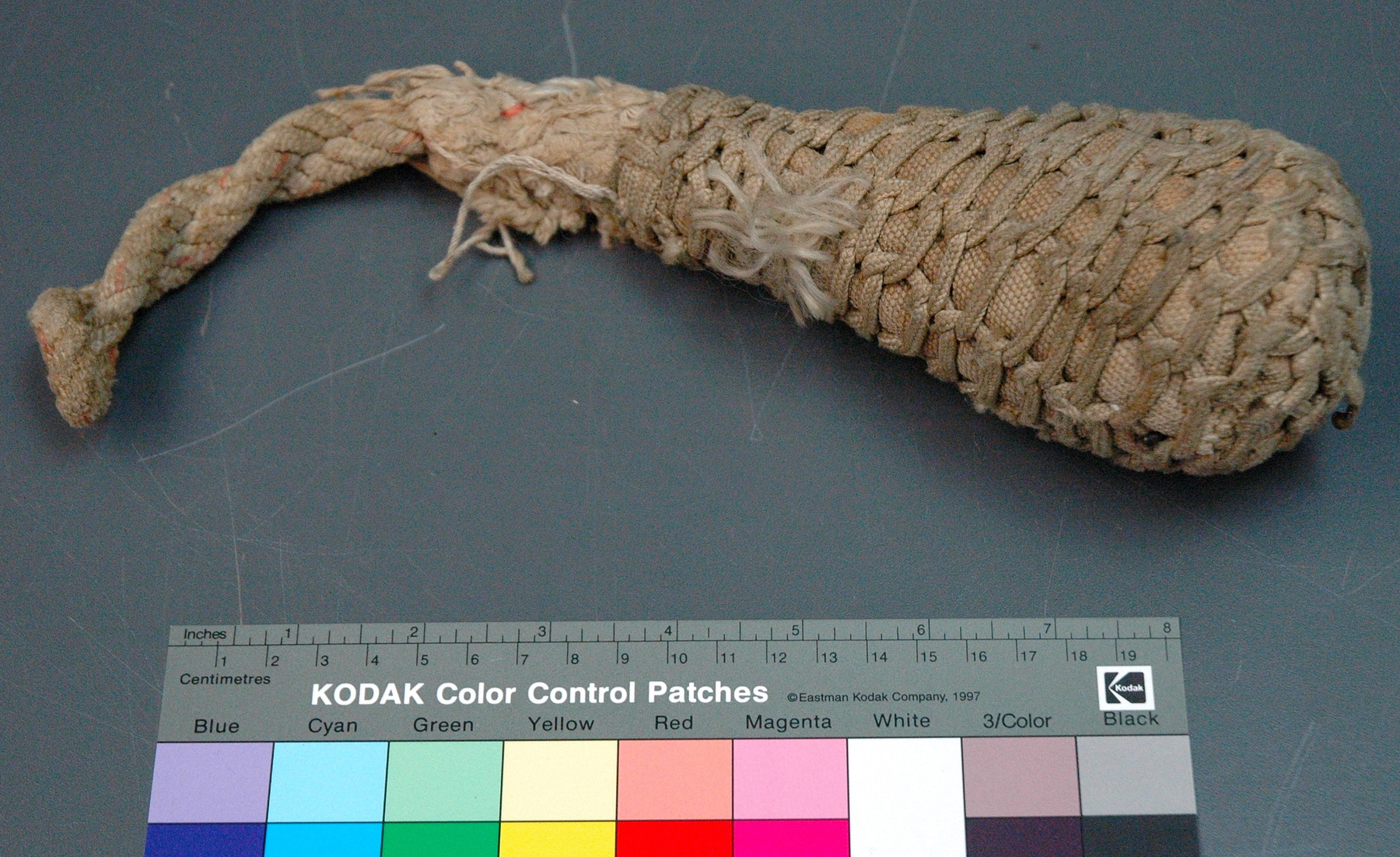

Synthetic fibres are woven into fabric on the same type of equipment as natural fibres. The manual and requisition forms that accompanied this donation suggest that this model S-5 silk loom was used by DuPont Canada in the production of rayon (or artificial silk, as it was known), nylon, and acetate textiles. The remnants of the cloth still present on the loom are labeled as “Nylon 2.” It is equipped with a Hunt Let-off – a mechanism that adjusted the warp tension depending on the load of the loom beans in order to maintain a constant balance. This contributed to the fabric evenness, reduced manufacturing defects and improved the effectiveness of the loom by reducing errors that forced operation interruptions. The loom was powered by an electric motor. This loom was manufactured by the Crompton and Knowles Corporation – a US company operating in Massachusetts that designed, patented, and manufactured a variety of complex textile machinery and the electric motors for it (Crompton & Knowles Loom Works. Weaving machinery for cotton, silk, woolen, worsted and special fabrics. Worcester, Mass., Crompton & Knowles Loom Works [c1918]). According to Alan McCullough, the Canadian textile industry generally imported technology (p11). DuPont Canada acquired this loom through Crompton and Knowles Canada, based in Montreal, which provided and installed equipment for Canadian mills. It also supplied spare parts, various accessories, and personnel to service the machines and train the mill employees. - Notes sur la région

-

Inconnu

Détails

- Marques

- MFR'S PLATES: 'CROMPTON & KNOWLES/ LOOM WORKS/ WORCESTER, MASS., U.S.A.' & 'S-5'/OTHER PLATE 'SILK LOOM'/ ON TAKE-OFF 'SOMACO/ GREER SC/ PAT 3320979'

- Manque

- S/O

- Fini

- PAINTED GREEN, NOT ORIGINAL FINISH/ SILVER-TONE PTS, SOME NOW APPEAR CORRODED, SOME VARNISHED WOOD PTS, SOME BLACK PTS

- Décoration

- S/O

FAIRE RÉFÉRENCE À CET OBJET

Si vous souhaitez publier de l’information sur cet objet de collection, veuillez indiquer ce qui suit :

Crompton & Knowles Loom Works, Métier à tisser, entre 1941–1957, Numéro de l'artefact 1987.2059, Ingenium - Musées des sciences et de l'innovation du Canada, http://collections.ingeniumcanada.org/fr/id/1987.2059.001/

RÉTROACTION

Envoyer une question ou un commentaire sur cet artefact.

Plus comme ceci