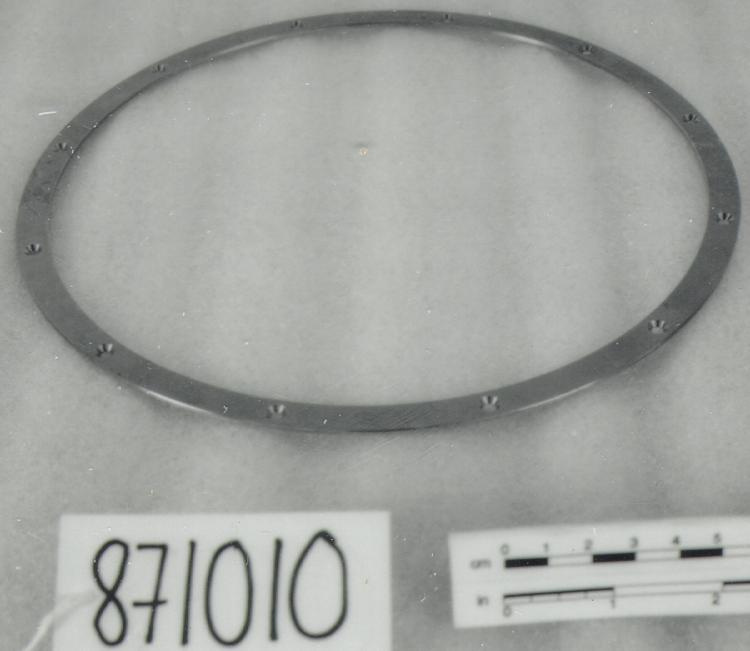

Bague

Utiliser cette image

Puis-je réutiliser cette image sans autorisation? Oui

Les images sur le portail de la collection d’Ingenium ont la licence Creative Commons suivante :

Copyright Ingenium / CC BY-NC-ND (Attribution-NonCommercial 4.0 International (CC BY-NC 4.0)

ATTRIBUER CETTE IMAGE

Ingenium,

1987.2661.004

Permalien:

Ingenium diffuse cette image sous le cadre de licence Creative Commons et encourage son téléchargement et sa réutilisation à des fins non commerciales. Veuillez mentionner Ingenium et citer le numéro de l’artefact.

TÉLÉCHARGER L’IMAGEACHETER CETTE IMAGE

Cette image peut être utilisée gratuitement pour des fins non commerciales.

Pour un usage commercial, veuillez consulter nos frais de reproduction et communiquer avec nous pour acheter l’image.

- TYPE D’OBJET

- S/O

- DATE

- 1978

- NUMÉRO DE L’ARTEFACT

- 1987.2661.004

- FABRICANT

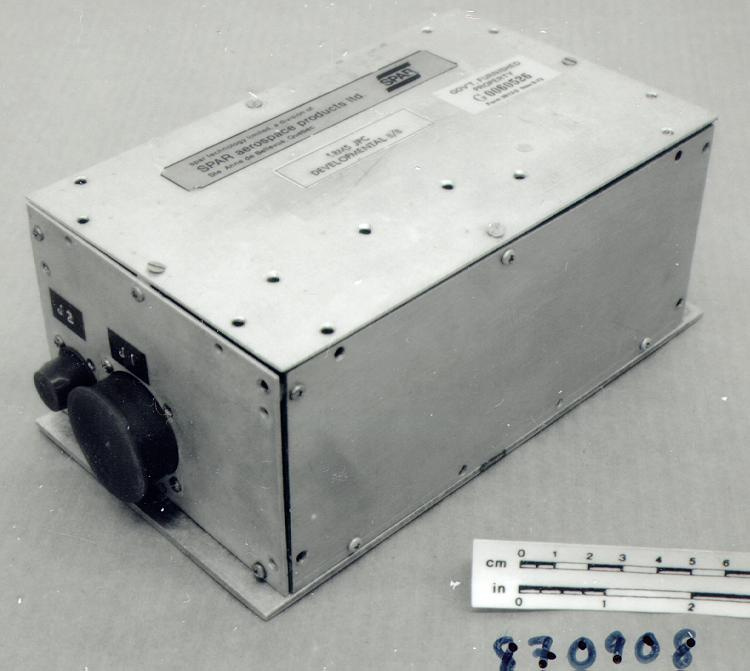

- SPAR AEROSPACE PRODUCTS LTD.

- MODÈLE

- 51140C1043-1

- EMPLACEMENT

- Toronto, Ontario, Canada

Plus d’information

Renseignements généraux

- Nº de série

- S/O

- Nº de partie

- 4

- Nombre total de parties

- 4

- Ou

- S/O

- Brevets

- S/O

- Description générale

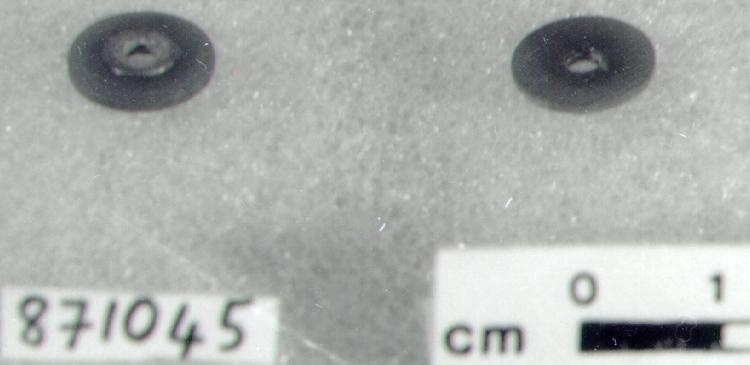

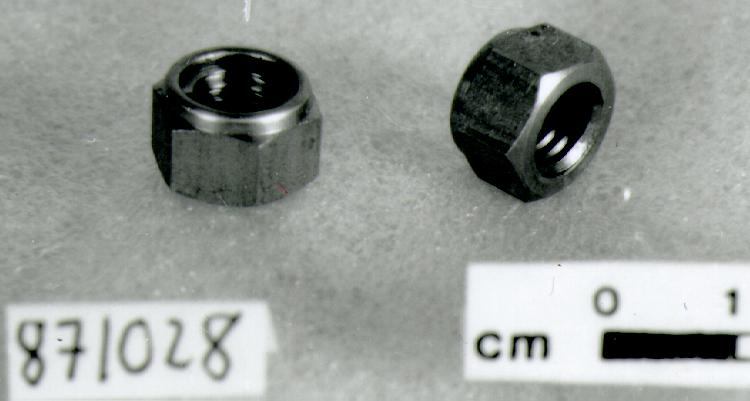

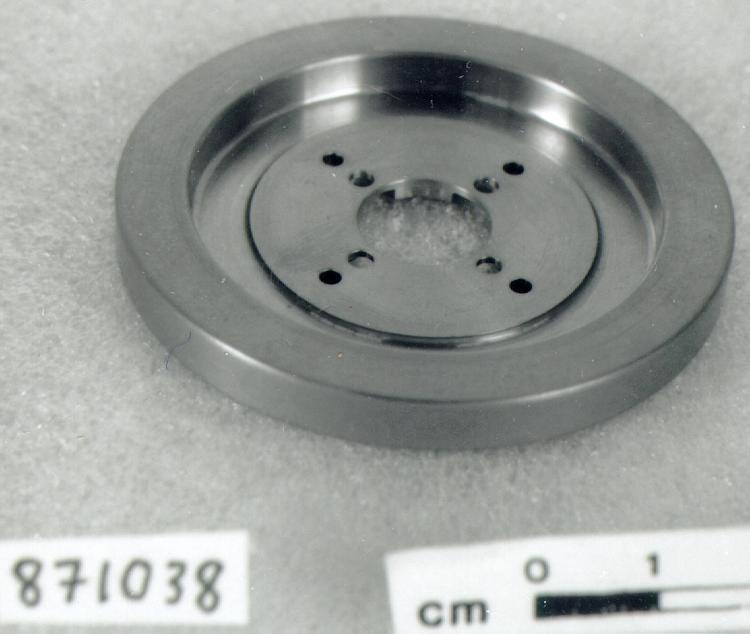

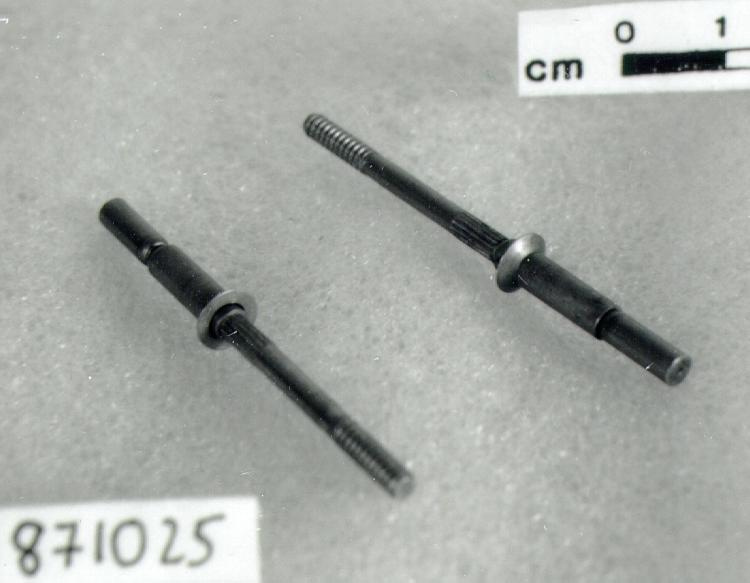

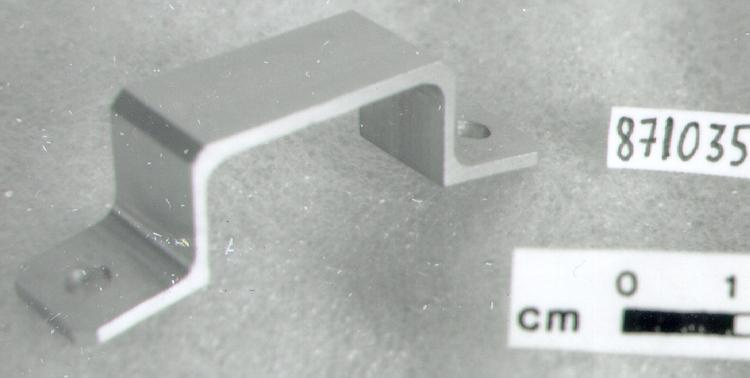

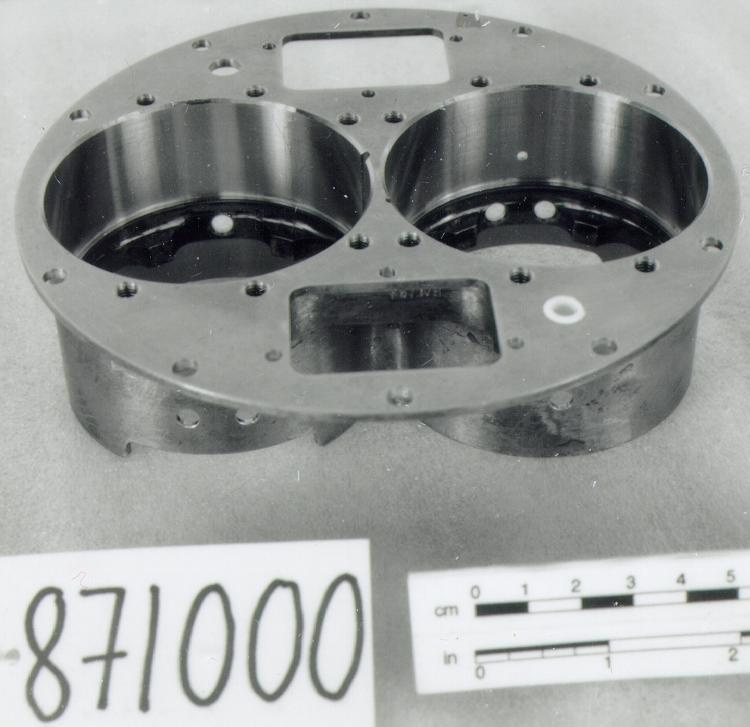

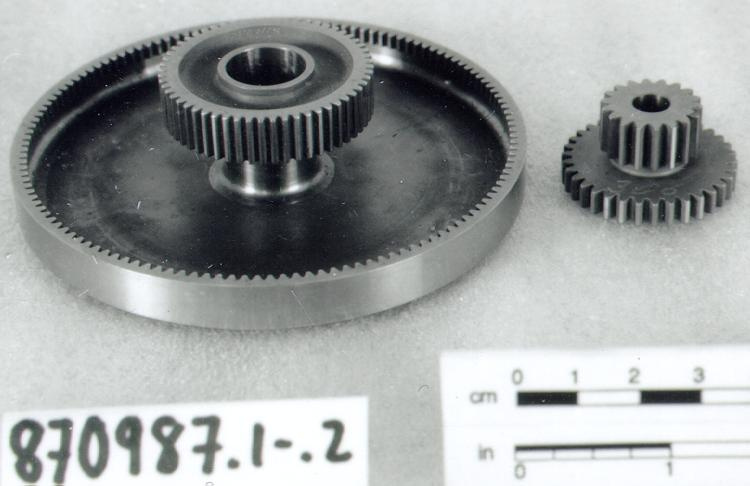

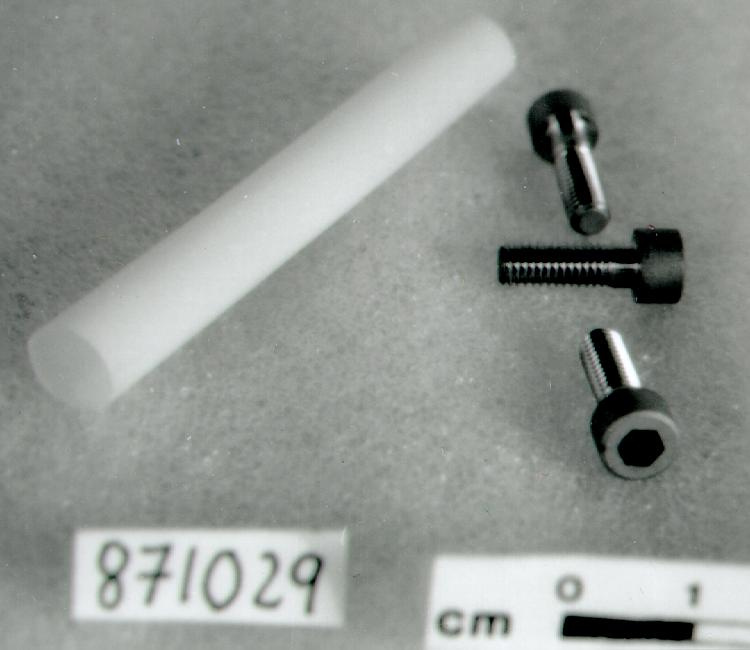

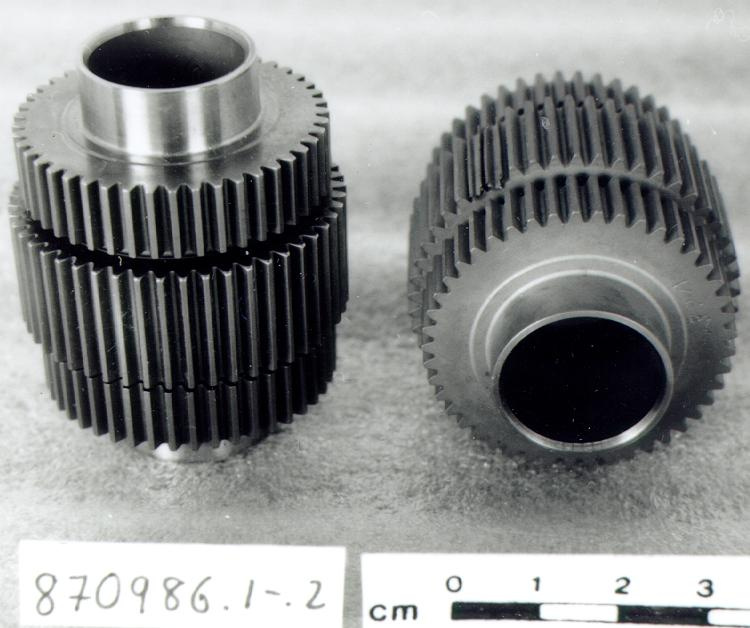

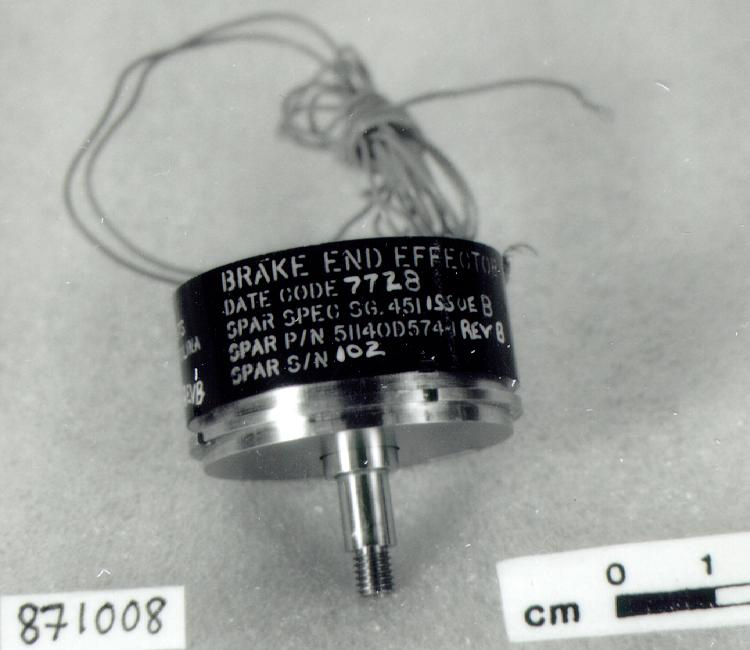

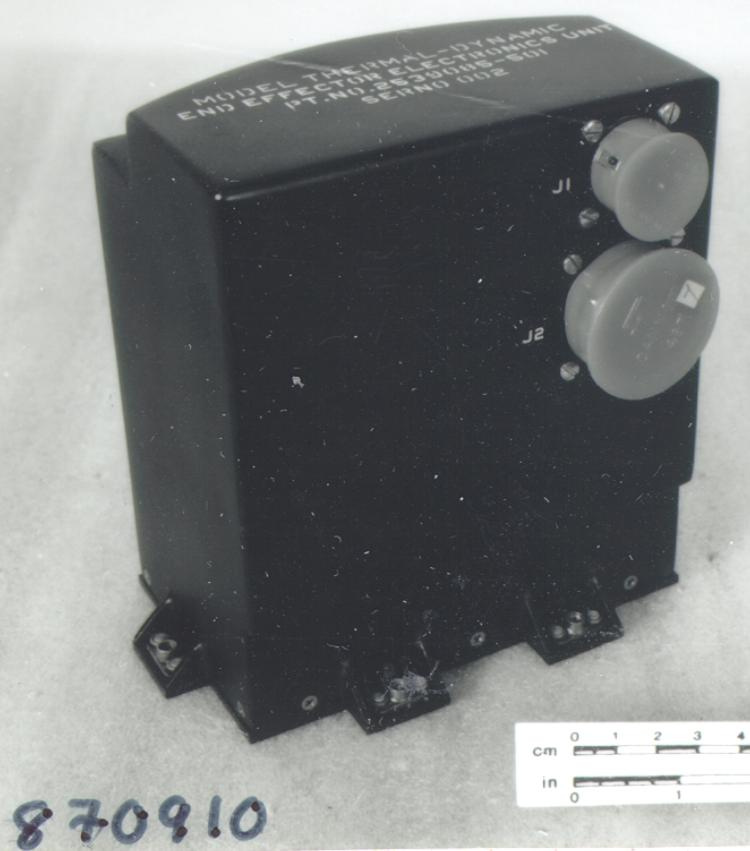

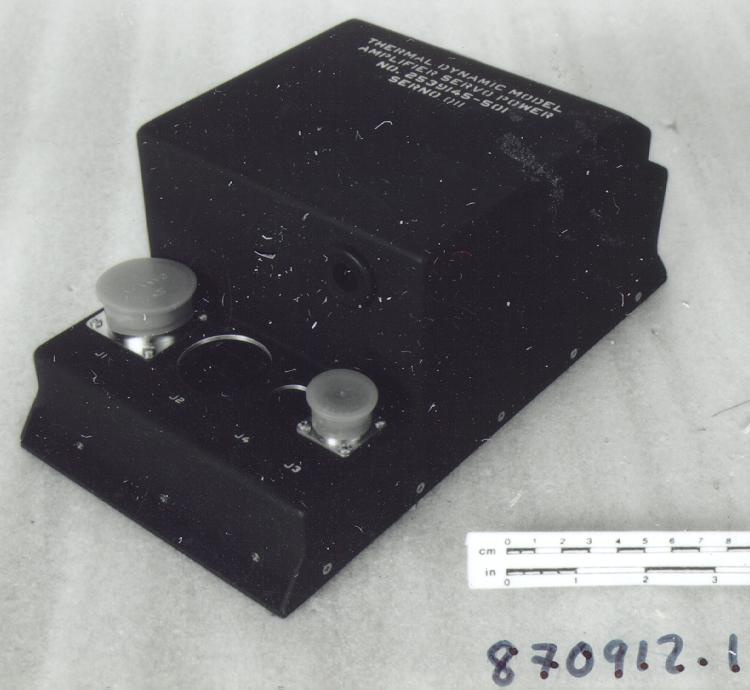

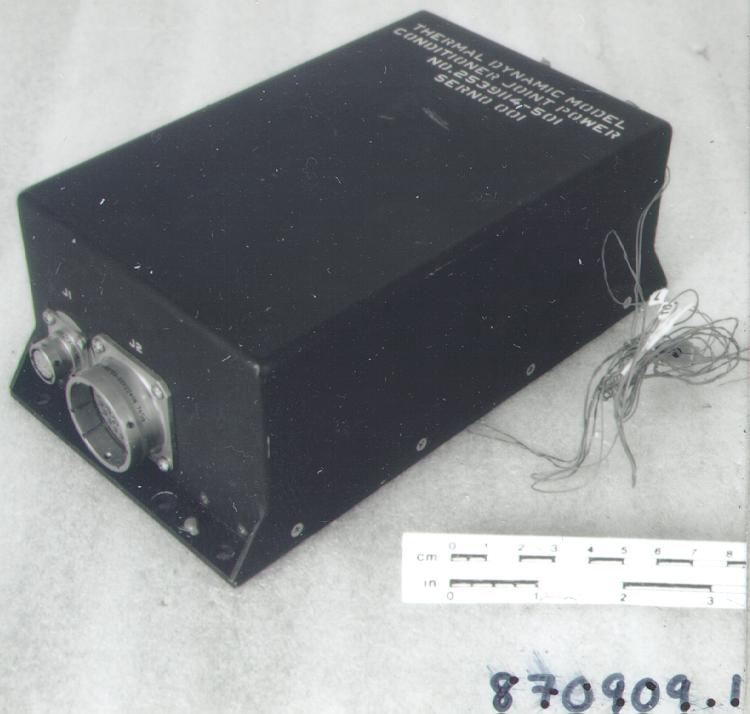

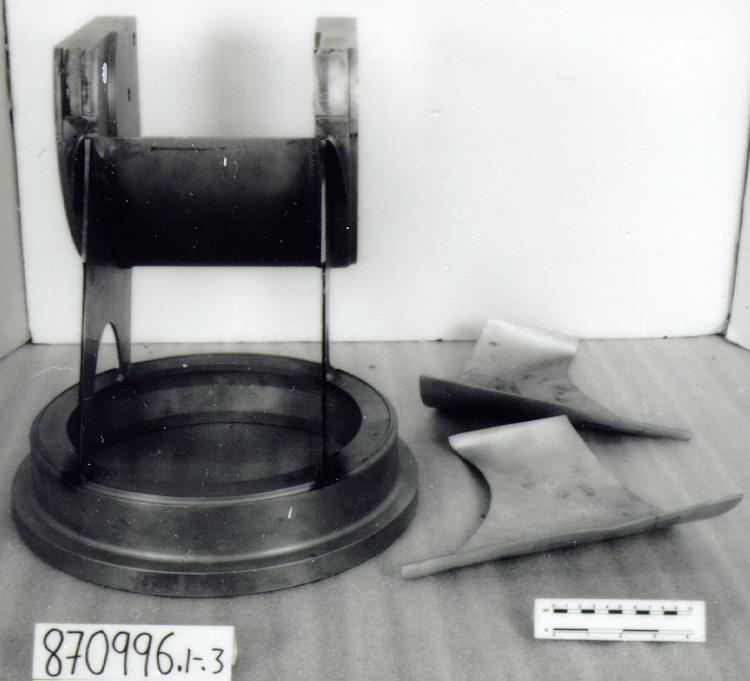

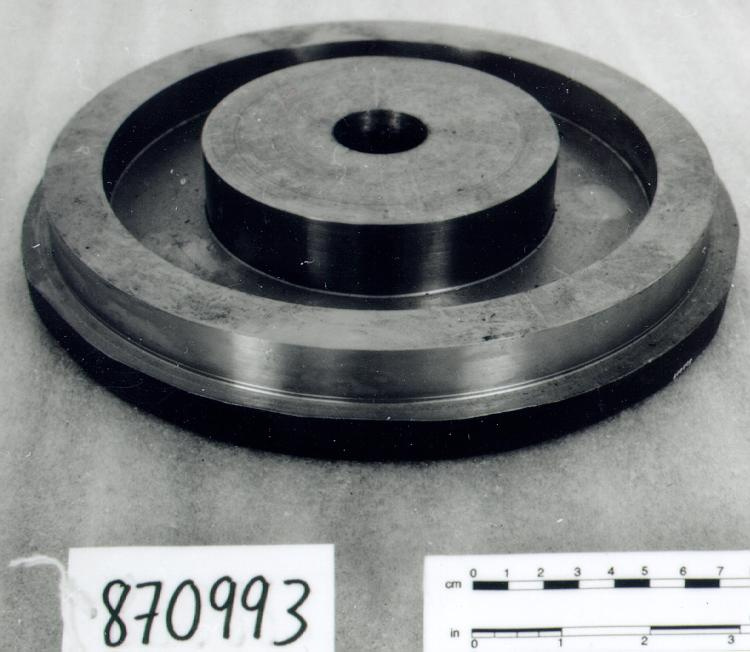

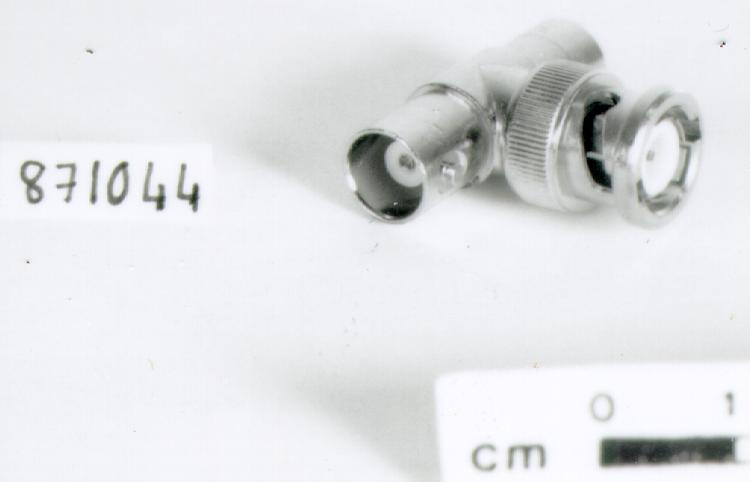

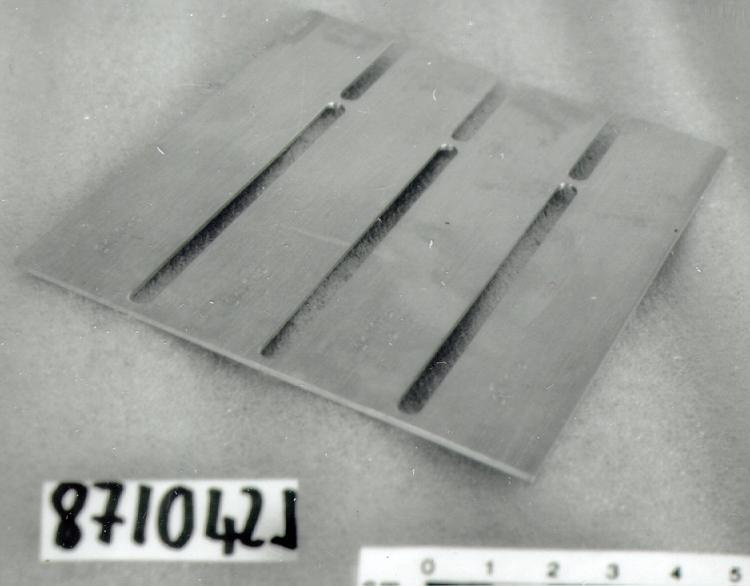

- Synthetic (possible) bushing in a synthetic enclosure

Dimensions

Remarque : Cette information reflète la taille générale pour l’entreposage et ne représente pas nécessairement les véritables dimensions de l’objet.

- Longueur

- 11,5 cm

- Largeur

- 10,0 cm

- Hauteur

- 2,4 cm

- Épaisseur

- S/O

- Poids

- S/O

- Diamètre

- S/O

- Volume

- S/O

Lexique

- Groupe

- Technologie de l'espace

- Catégorie

- Engin spatial habite

- Sous-catégorie

- S/O

Fabricant

- Ou

- SPAR

- Pays

- Canada

- État/province

- Ontario

- Ville

- Toronto

Contexte

- Pays

- Canada

- État/province

- Ontario

- Période

- Tested in May, 1978

- Canada

-

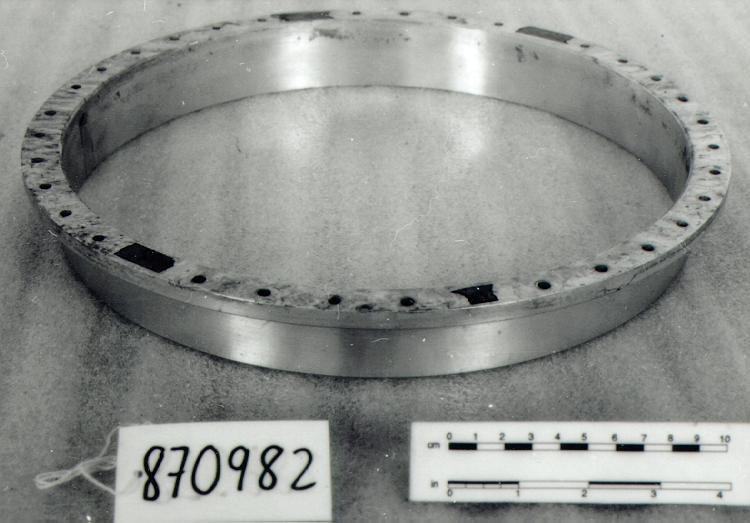

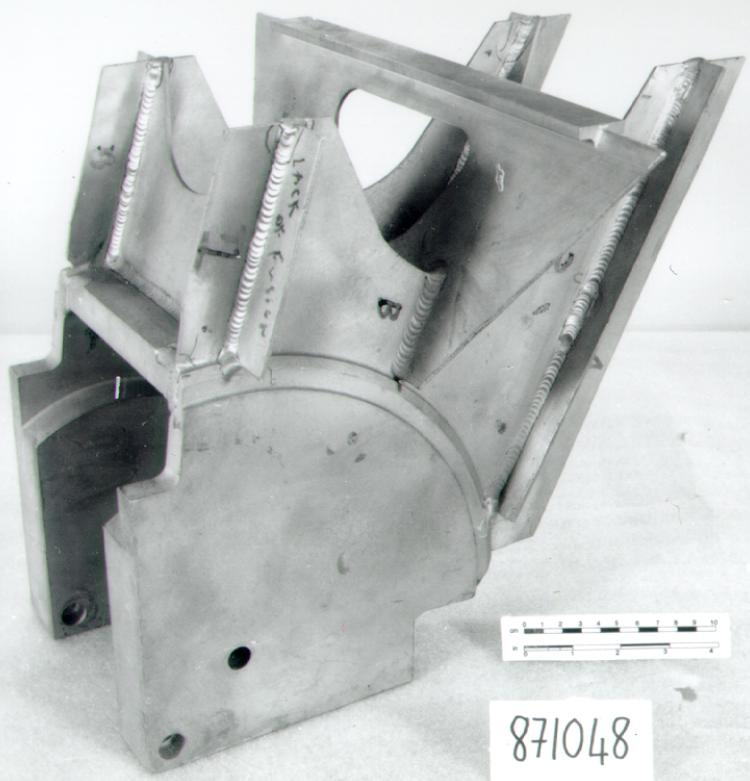

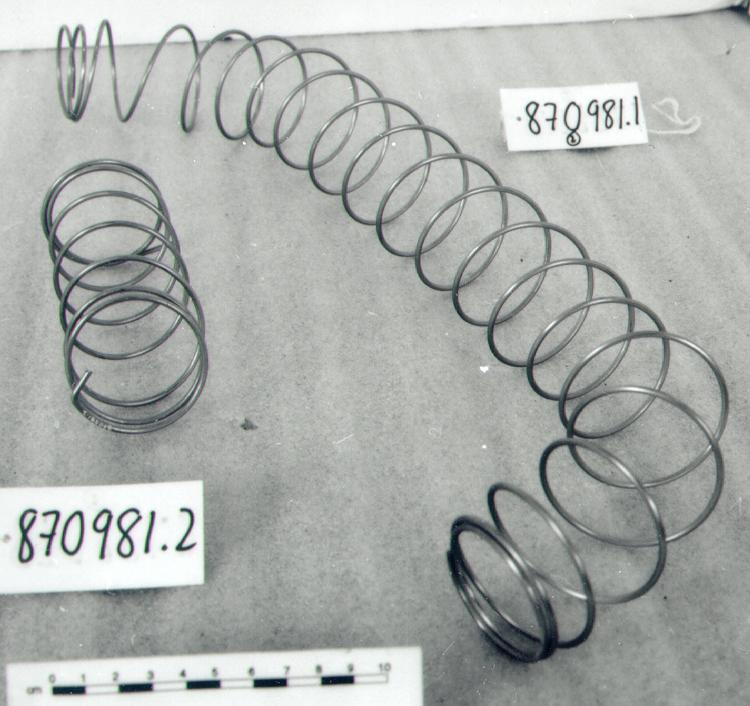

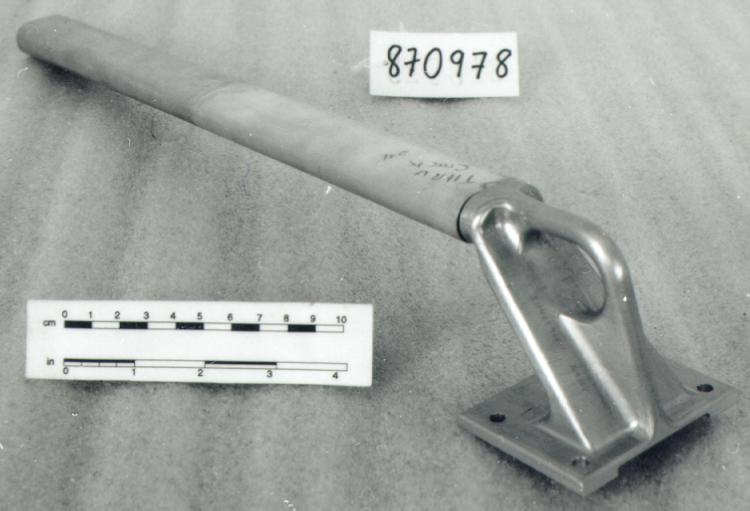

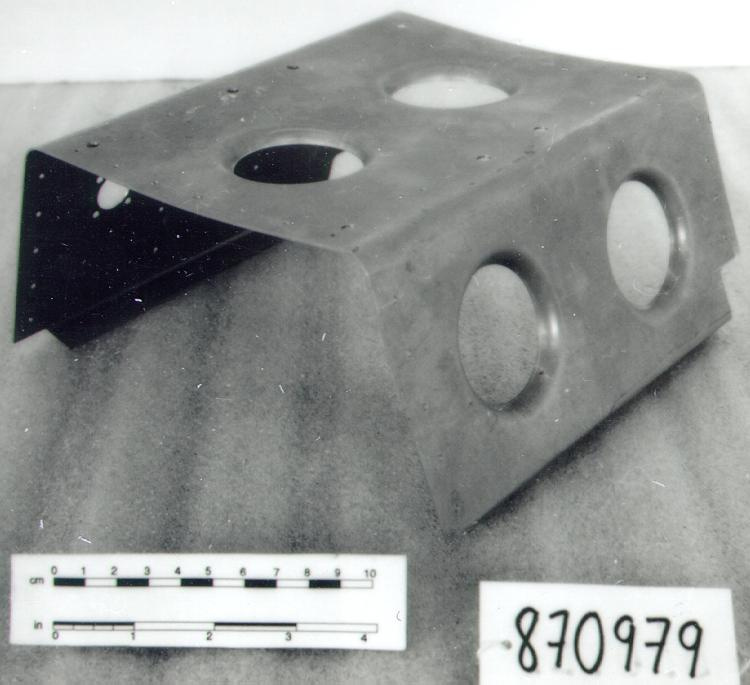

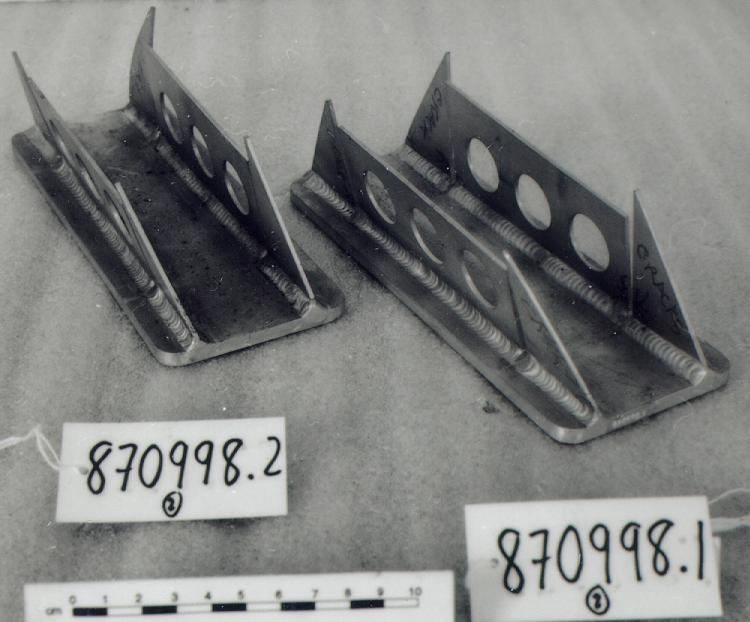

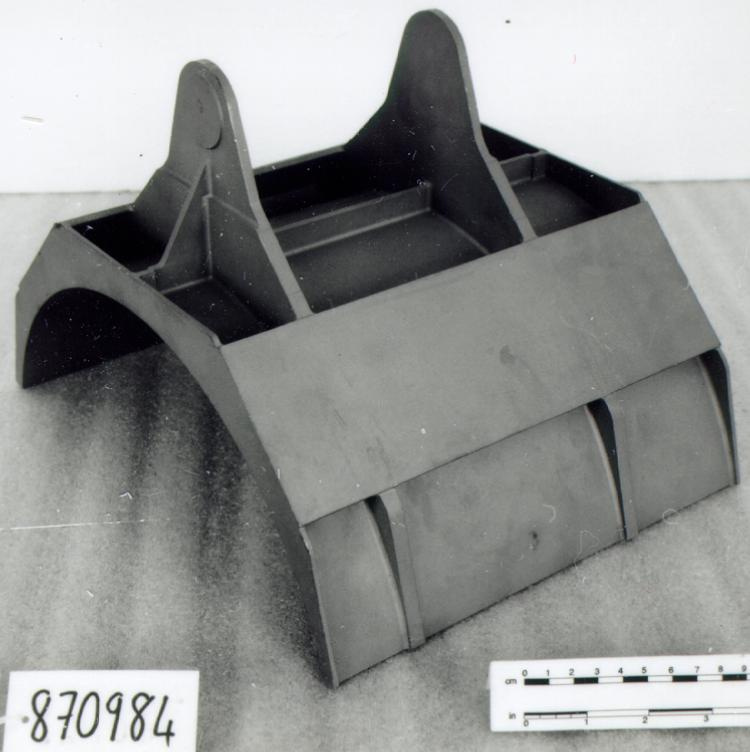

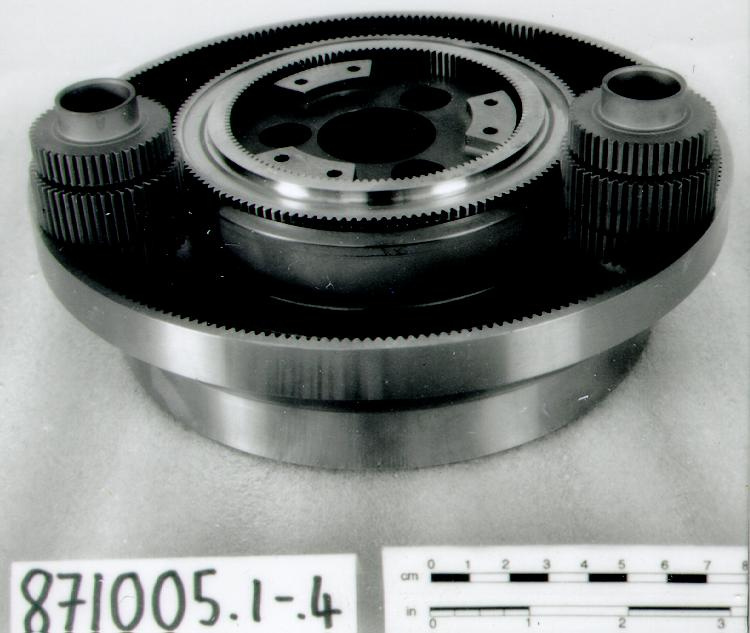

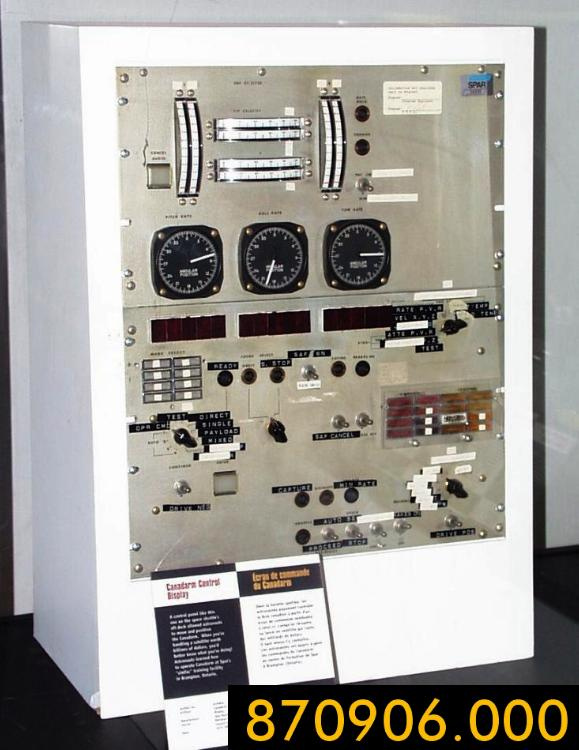

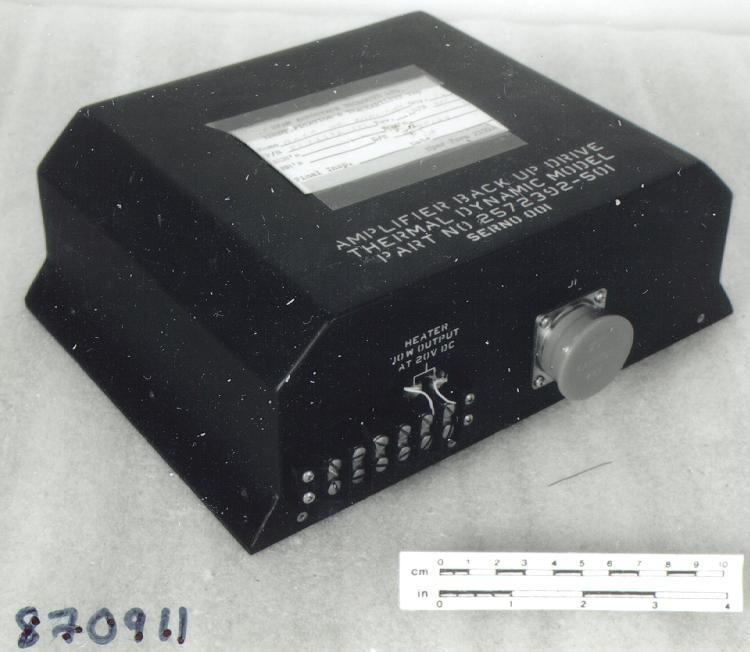

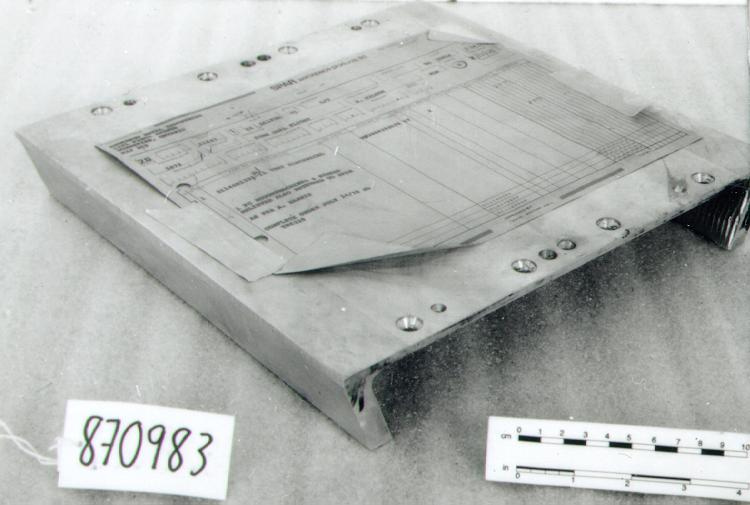

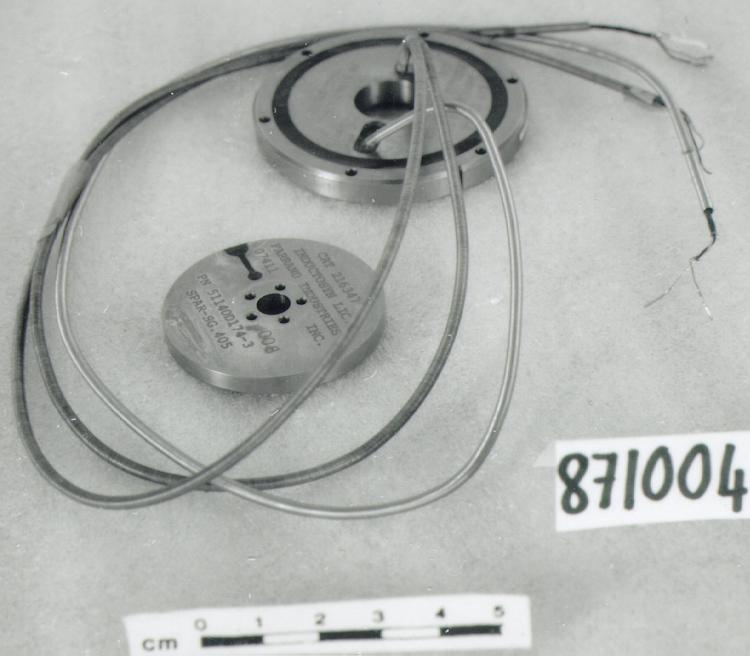

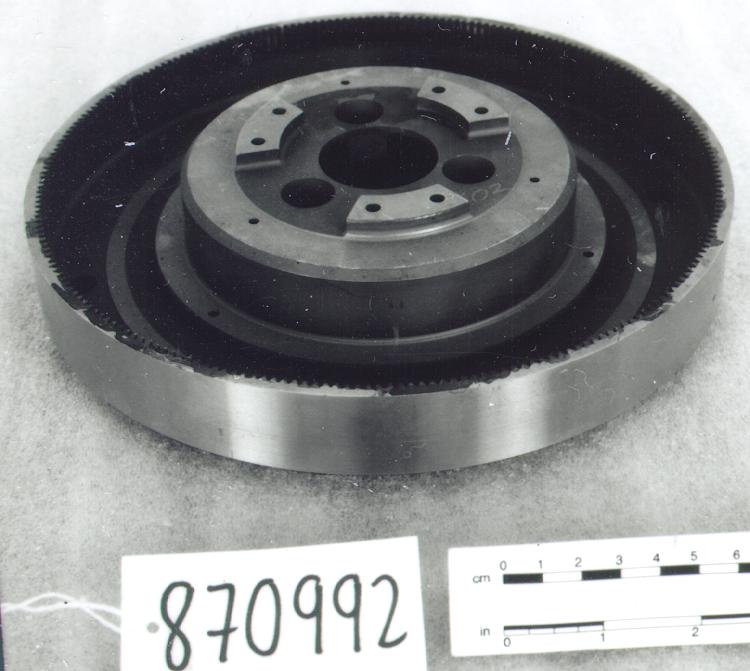

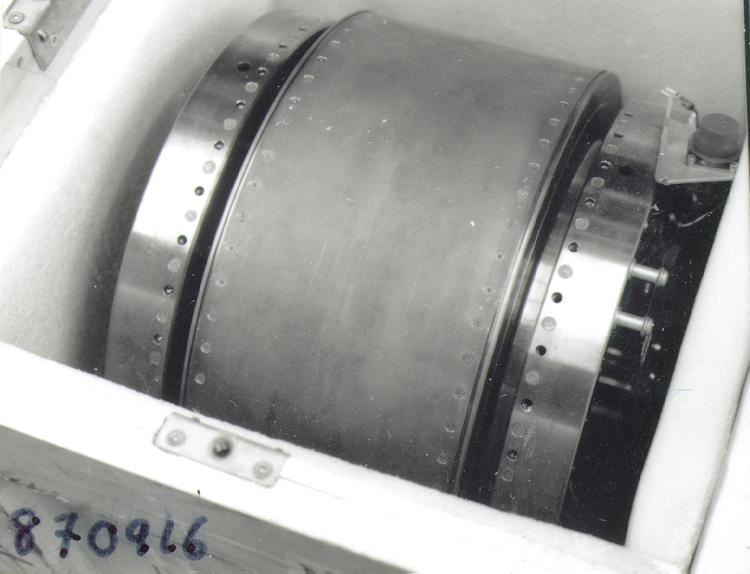

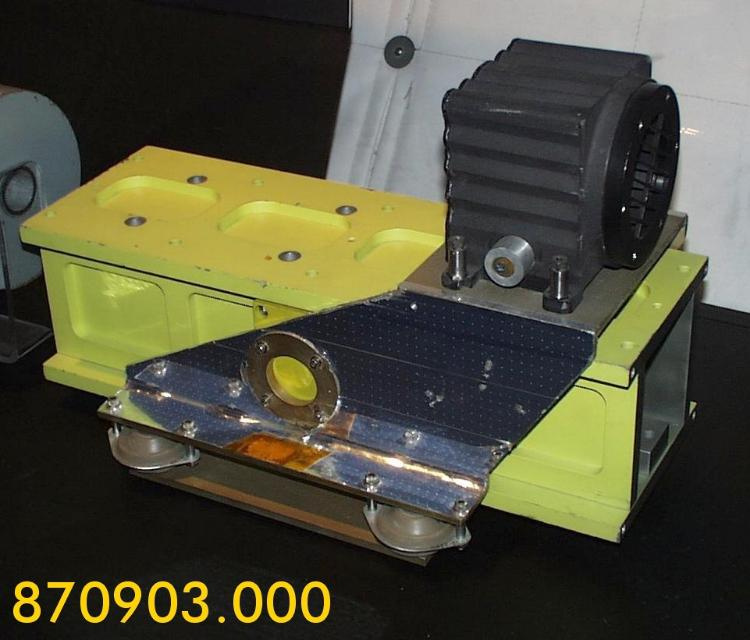

Canadian designed and built Canadarm was Canada’s contribution to U.S. Space Shuttle Program and successful commercial venture for Canada’s space industry. First RMS was manufactured by Canadian firms under contract to NRC and was given to NASA. NASA then purchased additional units to equip all orbital vehicles. Spar Aerospace, the Canadarm’s primary contractor, designed and built the Canadarm in Toronto to exacting criteria for precision movement, manual and automatic operations, safety, reliability, and weight. Although it had never been tested in the harsh environment of Space, the Canadarm worked flawlessly straight out of the box. - Fonction

-

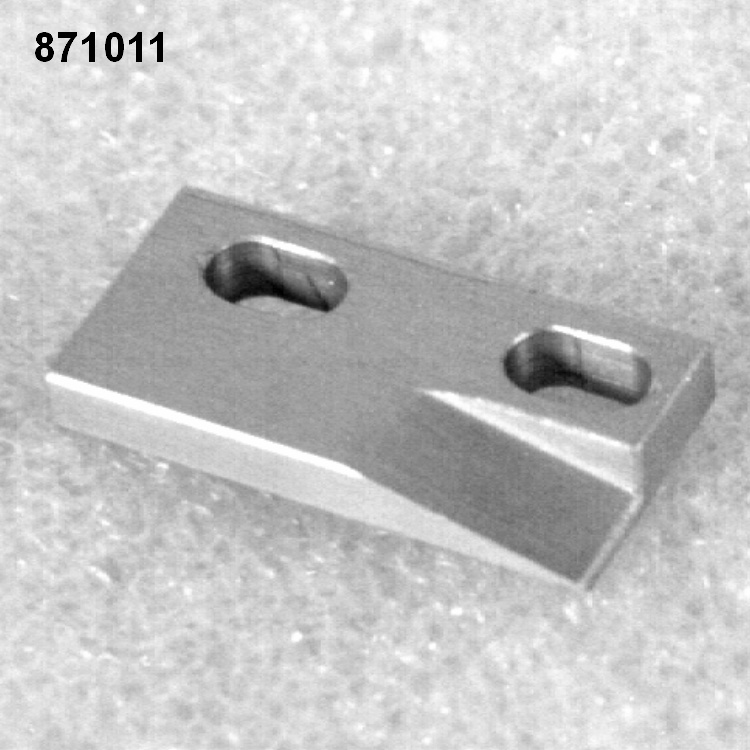

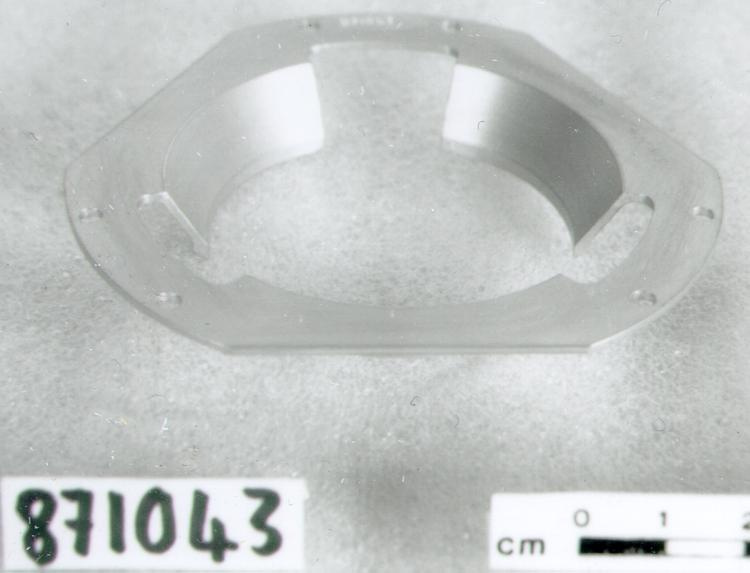

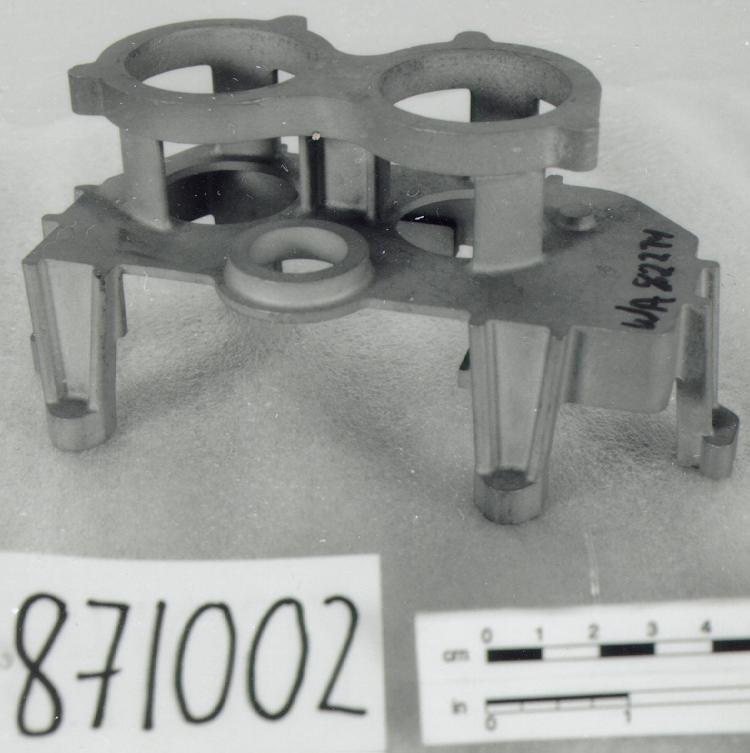

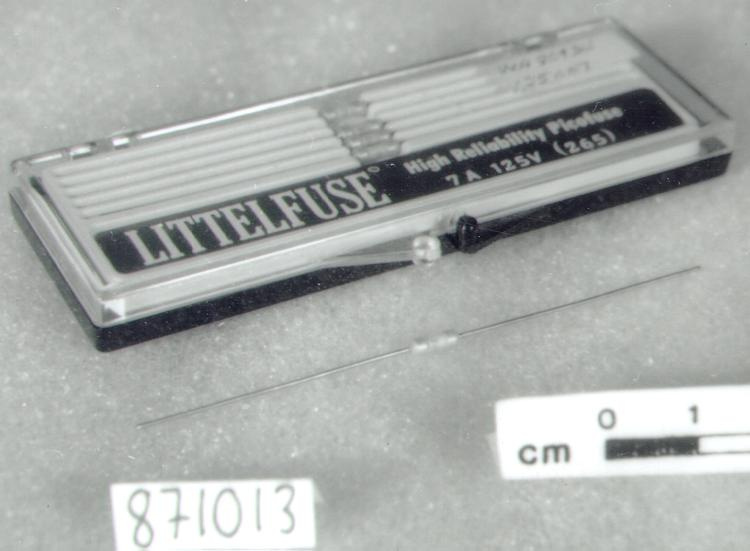

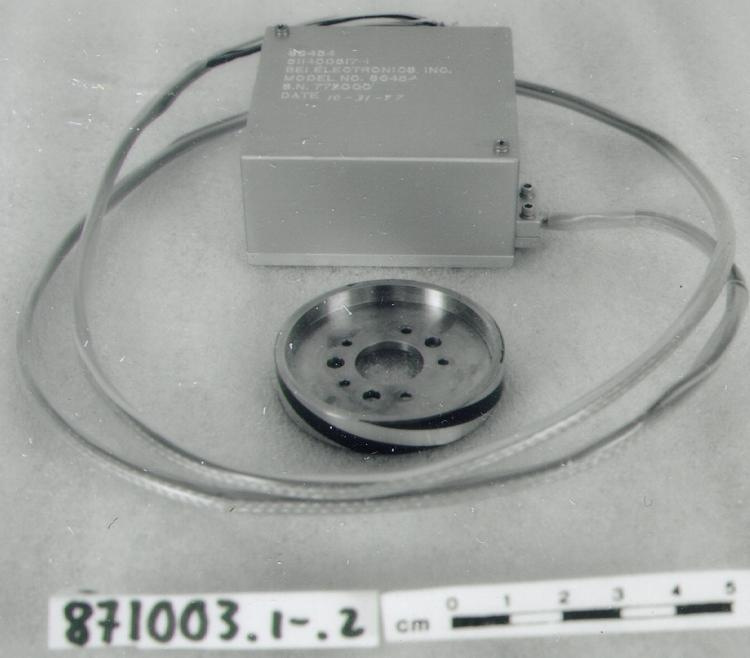

Parts from mock-up of various section of Canadarm, used and tested by engineers and technicians. - Technique

-

These pieces reflect the concentrated testing that took place on the Canadarm models represented in this artifact number series. The following passage, describing this research and development is taken from Glenn Gook’s The Canadian Designed and Built SPAR/MDA Canadarms: “Managing the number of parts and their inevitable design trade-offs turned out to be one of the most complex tasks associated with the delivery of the final product. To understand this challenge, one must realize that the final Canadarm had to be capable of operating from an even more complex machine (the Shuttle/Orbiter) with a stated reliability of 100%. Putting it more simply, it had to work first time and every time! NASA also stipulated that the arm must sustain two major component failures with no threat to the crew. Making it more difficult, this reliability had to be met in the absence of testing in the environment of space in which it was to operate. This testing could only be accomplished through the development of ground-based simulators.” (Ref.1) Two major forms of testing, or simulation, were required. The first, of which these pieces are related, allowed engineers to test the device on earth. As Gook describes, “the first earthbound simulator took the form of a specially designed steel rig on air-bearings that can be likened to air cushions. This system, located and installed at the Spar Robotics Ormont Drive plant in North York, allowed the rig to seamlessly glide across a perfectly smooth floor thereby simulating a single plane of motion. To test other planes of motion the arm would be turned 90 degrees until all planes had been tested. In this step-by-step manner the Canadarm was successfully evaluated and subsequently certified for space operation.” The second testing/simulation focused on training astronauts on the ground so they could become familiar with the arm’s response times as they would exist in a microgravity or weightless environment. (Ref.1) Tested parts were either approved for use or rejected. Parts were rejected for a number of reasons that resulted from a variety of malfunctions. Engineers documented testing outcomes on colour coded cards and attached them to the approved or rejected parts. When the NRC transferred the Canadarm models to Ingenium, the corporation received two large crates full of tested parts. These parts ranged in size from large covering plates to very, very small fittings. See worksheet for photo of crates of parts. - Notes sur la région

-

Inconnu

Détails

- Marques

- Tag found with bushing: "SPAR AEROSPACE PRODUCTS LTD./ IDENTIFICATION & TRACEABILITY TAG/ Name Bushing Qty. 2/ P/N 51140C1043-1 Rec. - S/N/ ECN's MSR's/ MR's D/S 39022/ Final Insp. Date/ Spar Form 2191A"/ On second tagged stapled to the first: "ANDERSON METAL INDUSTRIES INC./ #5948/ DESCRIPTION BUSHING/ PART NO. 51140C 1043-1/ SERIAL NO 2 Pcs/ ACCEPTED" Both tags in supplementary information file, see References

- Manque

- None apparent

- Fini

- Black bushing in a clear, sealed synthetic enclosure.

- Décoration

- S/O

FAIRE RÉFÉRENCE À CET OBJET

Si vous souhaitez publier de l’information sur cet objet de collection, veuillez indiquer ce qui suit :

SPAR AEROSPACE PRODUCTS LTD., Bague, vers 1978, Numéro de l'artefact 1987.2661, Ingenium - Musées des sciences et de l'innovation du Canada, http://collections.ingeniumcanada.org/fr/id/1987.2661.004/

RÉTROACTION

Envoyer une question ou un commentaire sur cet artefact.

Plus comme ceci