Camion

Utiliser cette image

Puis-je réutiliser cette image sans autorisation? Oui

Les images sur le portail de la collection d’Ingenium ont la licence Creative Commons suivante :

Copyright Ingenium / CC BY-NC-ND (Attribution-NonCommercial 4.0 International (CC BY-NC 4.0)

ATTRIBUER CETTE IMAGE

Ingenium,

2007.0002.001

Permalien:

Ingenium diffuse cette image sous le cadre de licence Creative Commons et encourage son téléchargement et sa réutilisation à des fins non commerciales. Veuillez mentionner Ingenium et citer le numéro de l’artefact.

TÉLÉCHARGER L’IMAGEACHETER CETTE IMAGE

Cette image peut être utilisée gratuitement pour des fins non commerciales.

Pour un usage commercial, veuillez consulter nos frais de reproduction et communiquer avec nous pour acheter l’image.

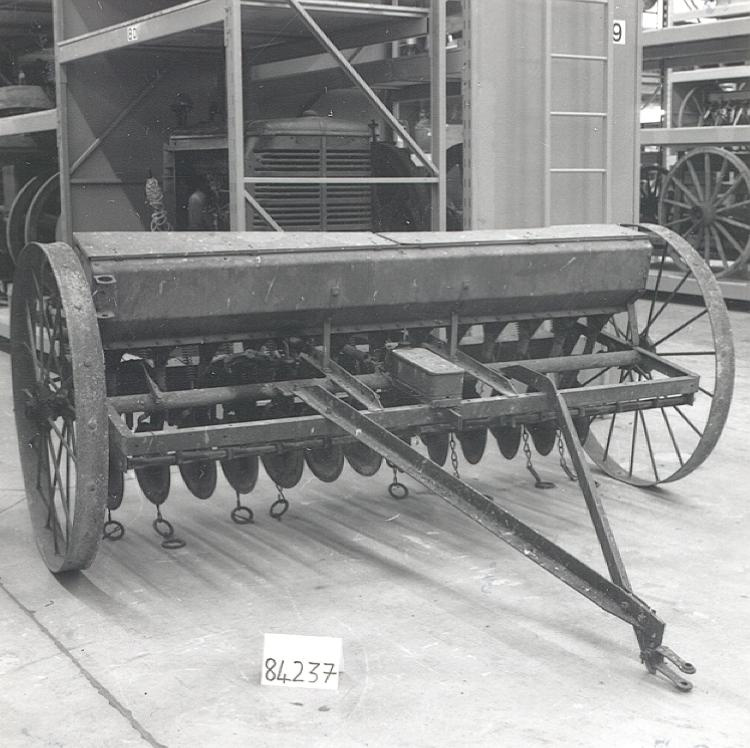

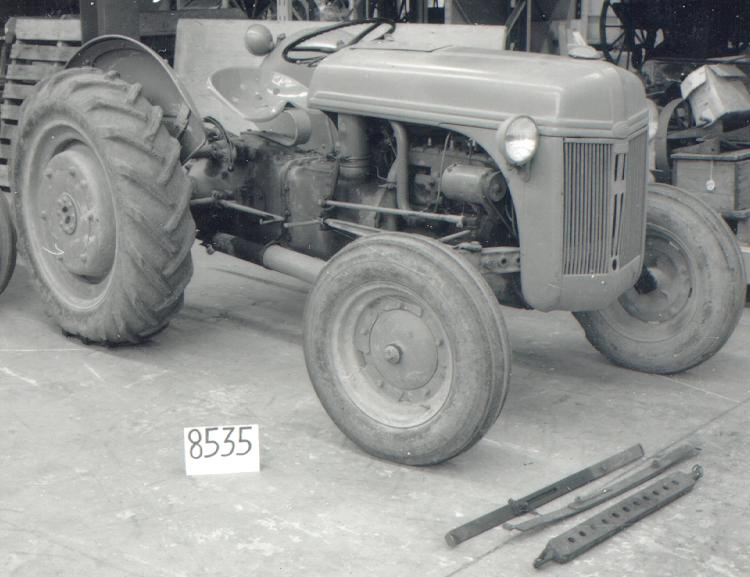

- TYPE D’OBJET

- grain

- DATE

- 1968

- NUMÉRO DE L’ARTEFACT

- 2007.0002.001

- FABRICANT

- International Harvester Co. of Canada Ltd.

- MODÈLE

- Loadstar 1600

- EMPLACEMENT

- Hamilton, Ontario, Canada

Plus d’information

Renseignements généraux

- Nº de série

- 416600C021003

- Nº de partie

- 1

- Nombre total de parties

- 1

- Ou

- S/O

- Brevets

- S/O

- Description générale

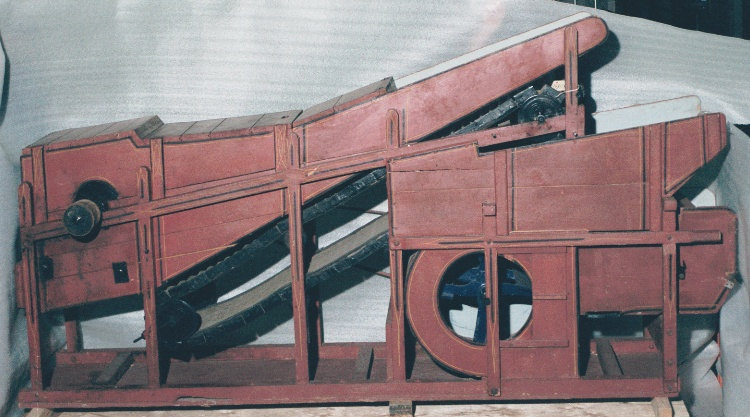

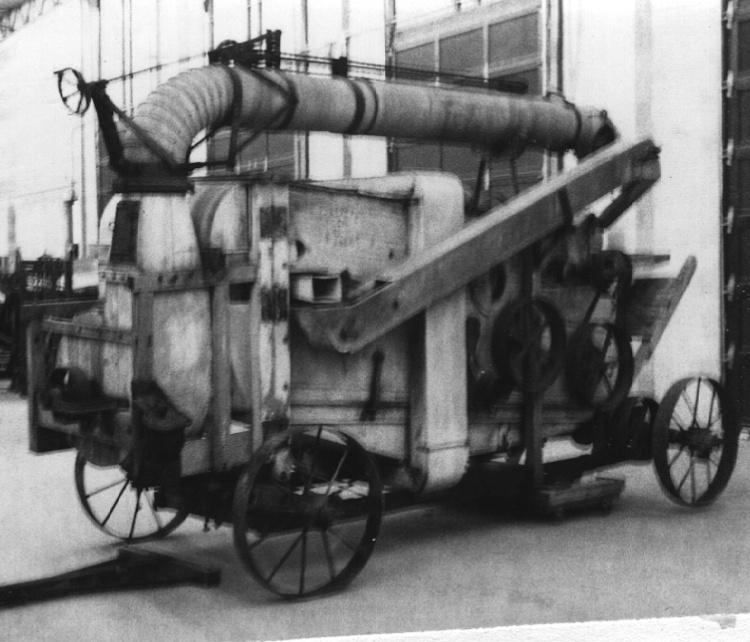

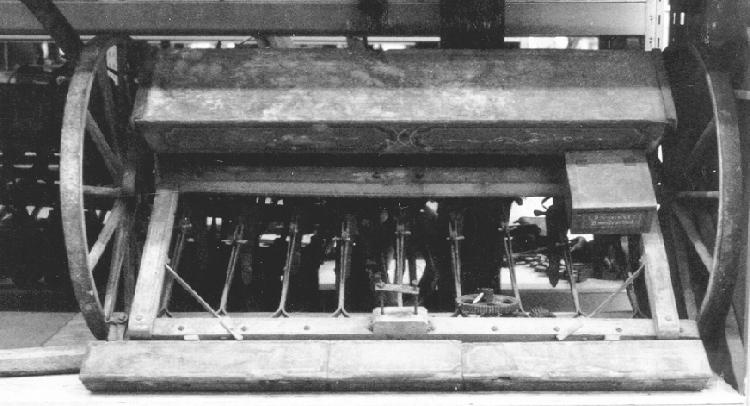

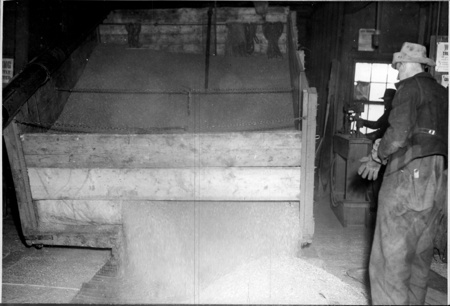

- metal body, chassis, engine, controls, parts/ wood grain box with metal fittings/ metal auger/ glass windows and head lamps/ synthetic seat covers, dashboard, steering wheel, controls, parts/ rubber tires, hoses

Dimensions

Remarque : Cette information reflète la taille générale pour l’entreposage et ne représente pas nécessairement les véritables dimensions de l’objet.

- Longueur

- 714,0 cm

- Largeur

- 276,0 cm

- Hauteur

- 275,0 cm

- Épaisseur

- S/O

- Poids

- S/O

- Diamètre

- S/O

- Volume

- S/O

Lexique

- Groupe

- Transports terrestres motorisés

- Catégorie

- Véhicules automobile

- Sous-catégorie

- S/O

Fabricant

- Ou

- IH

- Pays

- Canada

- État/province

- Ontario

- Ville

- Hamilton

Contexte

- Pays

- Canada

- État/province

- Saskatchewan

- Période

- 1968-2006

- Canada

-

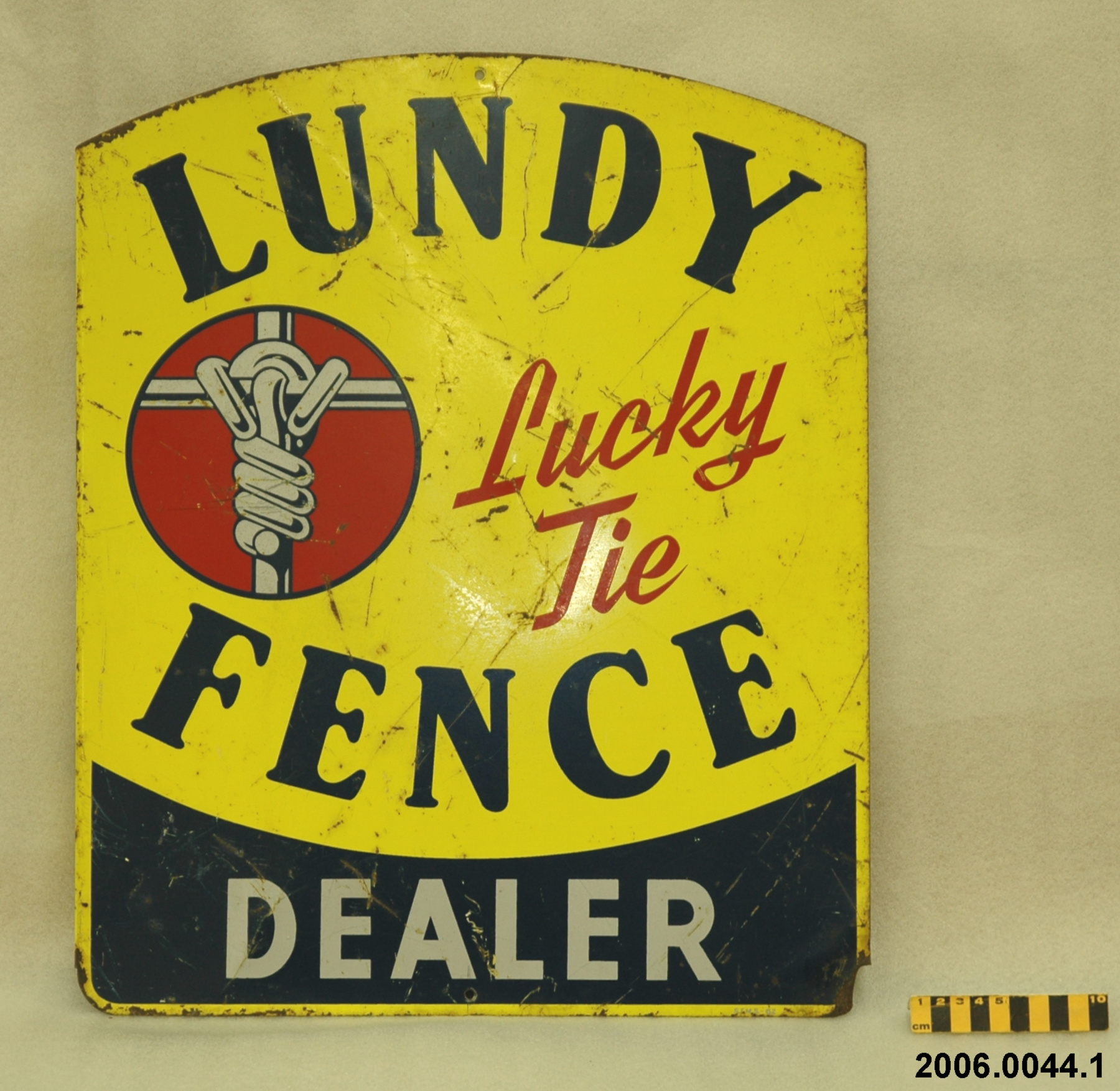

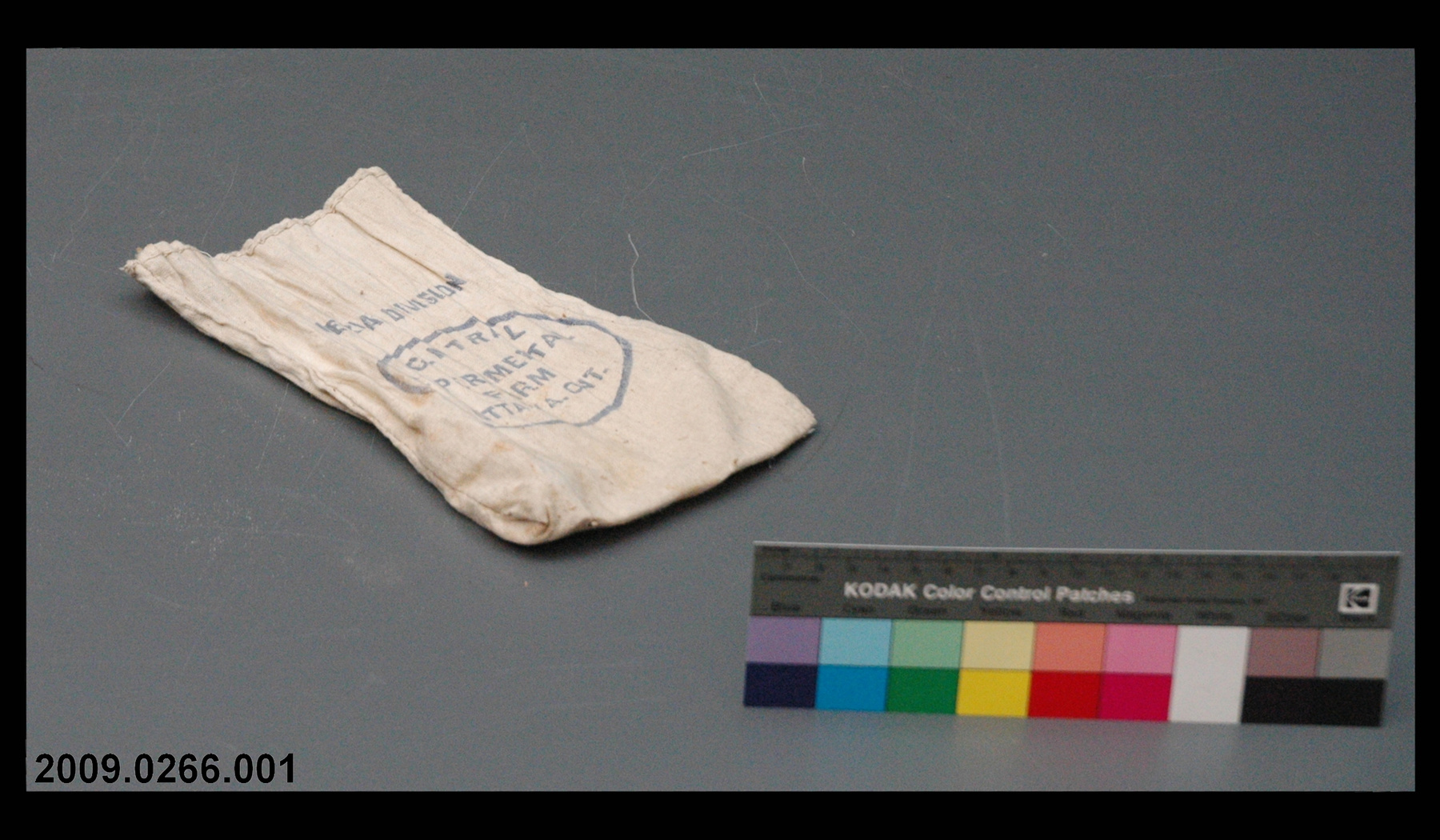

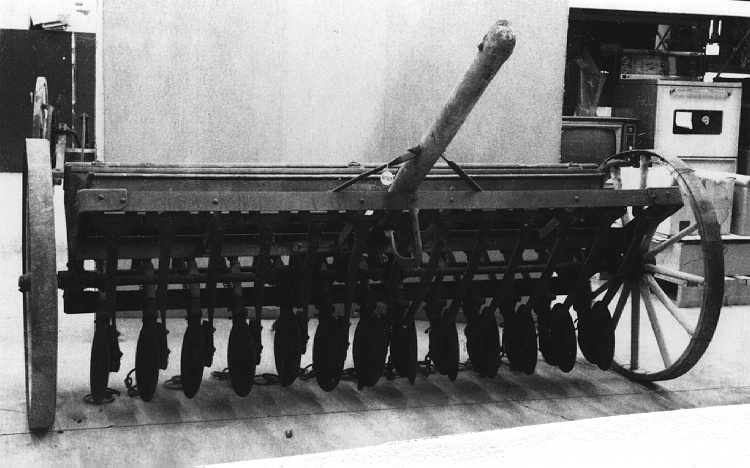

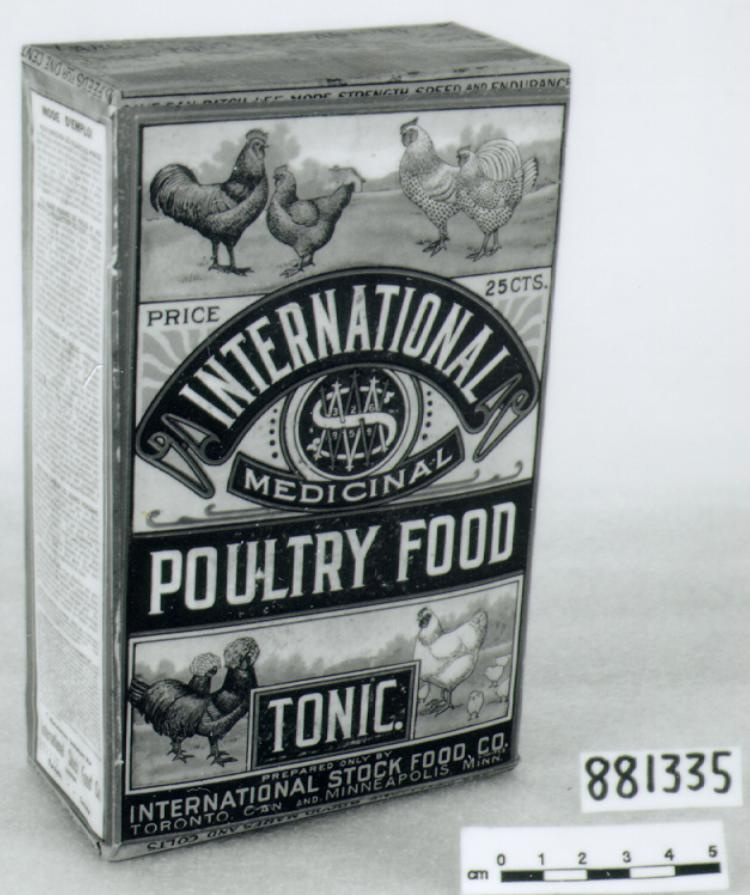

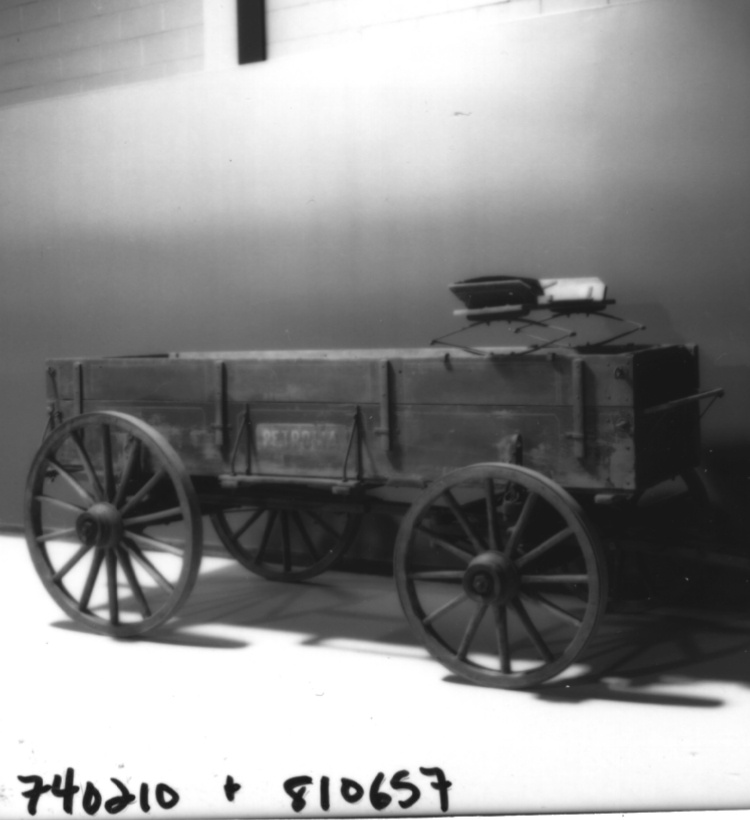

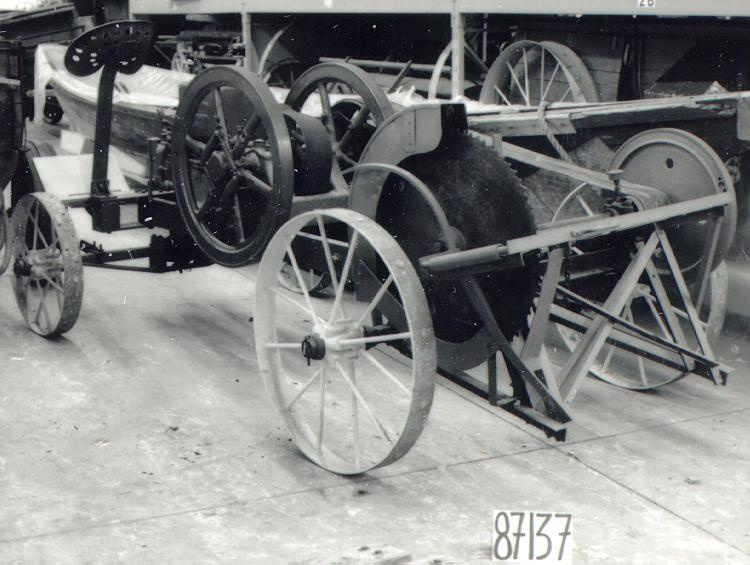

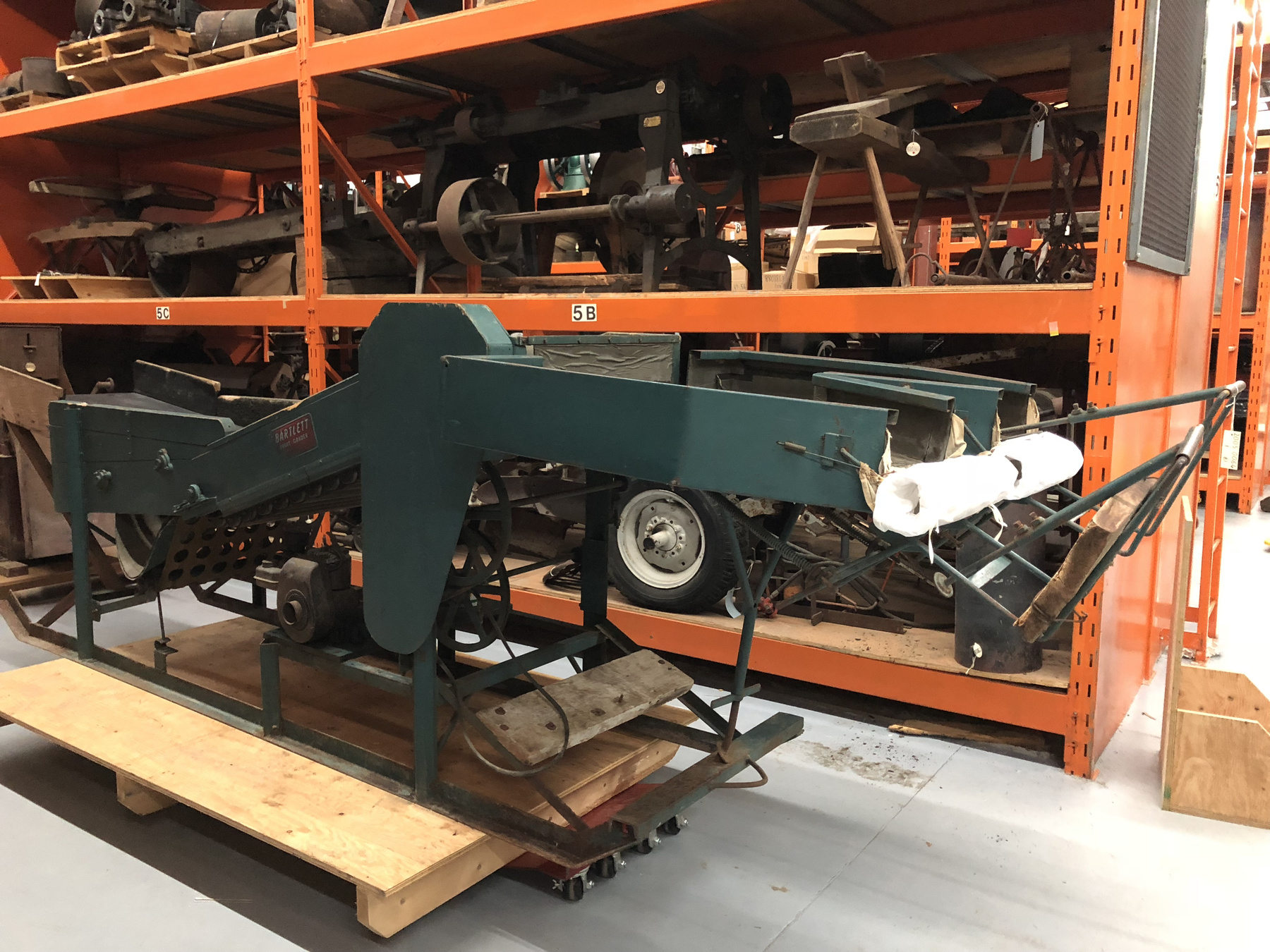

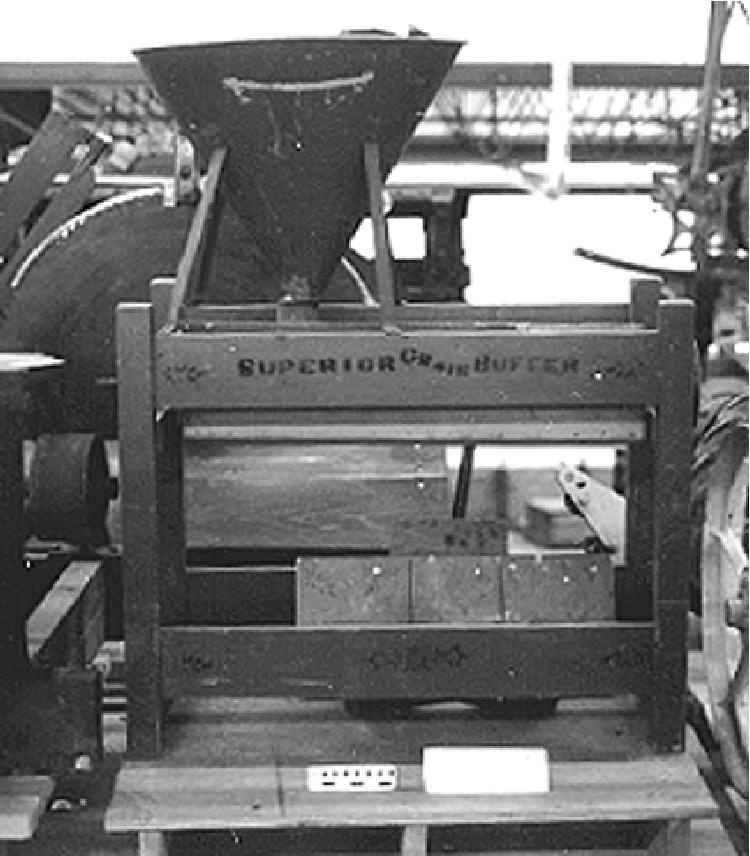

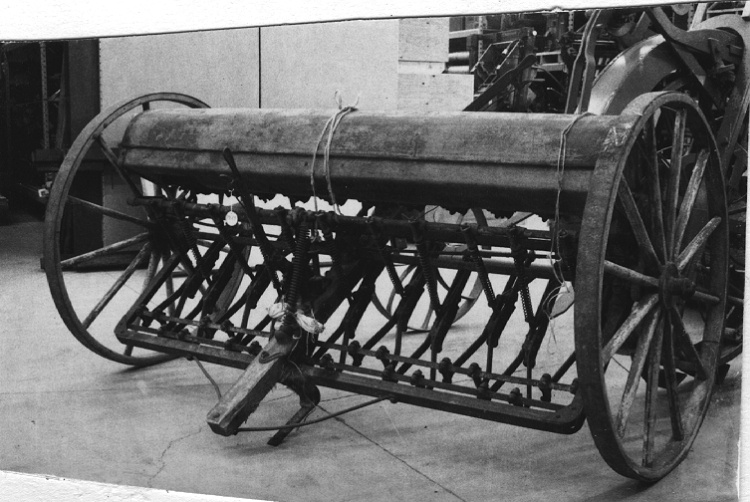

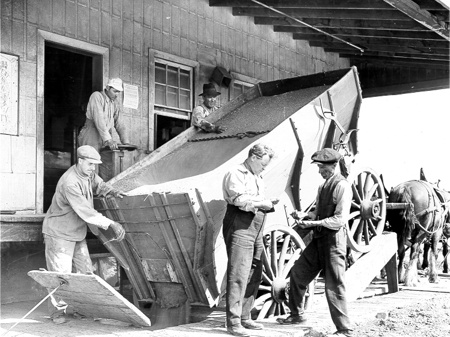

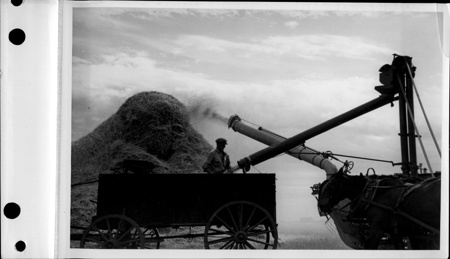

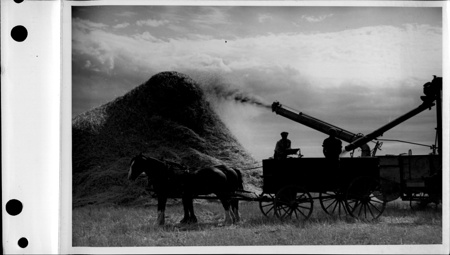

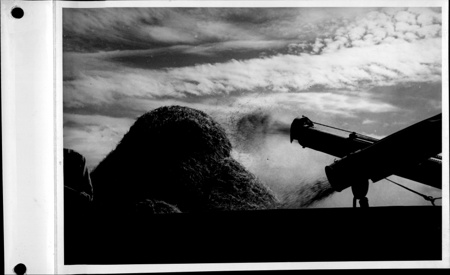

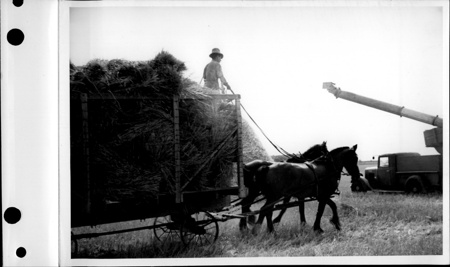

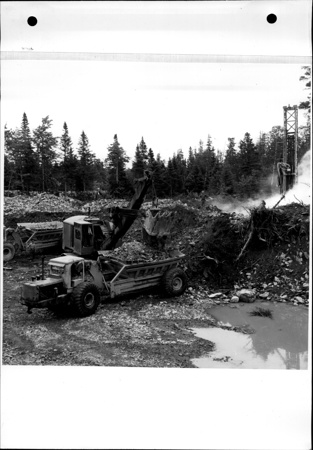

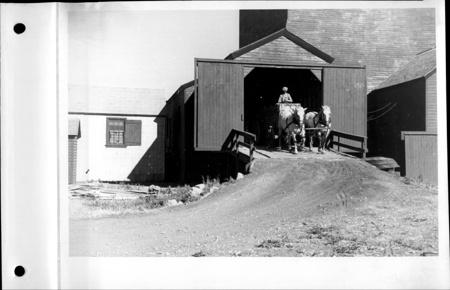

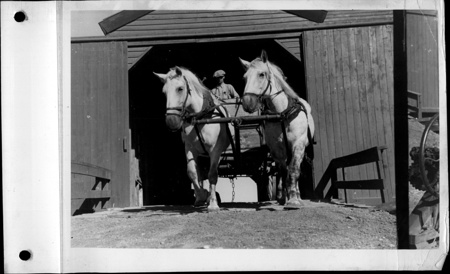

A piece of Canadian made grain farming equipment used on a Saskatchewan farm. Both the truck and the auger were purchased new by the Wanner family for use on their three quarters of farm land. The 1968 truck was purchased from the International Harvester dealership in Estevan by Terry Wanner=s dad, and it was then driven to Rosetown where a firm there manufactured the wooden grain box. The Aplumbing@ to permit the use of a hydraulic auger was installed about the same time the auger was purchased. The auger was purchased by the two sons and their father when the farm was being run in partnership (the father has since died). The truck was used to haul to the grain elevator at Macoun and to the field to fill grain drills each Spring. With the demolition of the elevator about ten years ago most recently the truck has been used to haul grain to the fields to fill the seed drill. The auger was used on the Loadstar truck for these drill filling exercises. Like many other grain farmers the Wanner brothers now cooperatively own a large highway transport with grain trailers to haul to the elevator in Estevan or at times to Regina. The auger has been replaced with a newer, larger flow capacity side mount model that is better suited to the highway trailers. The majority of the truck manufacturers active in the Canadian retail market have offered a truck and chassis option for farmers onto which to have a grain box mounted. Of these firms, International Harvester Corporation had an advantage due to the early establishment of its equipment marketing network and farmers' familiarity with its name and (hopefully) positive reputation. Although by the 1920s it had become clear that large scale farm equipment manufacturing in Canada would be limited to eastern Canada and in particular Ontario, there was a very clear niche in the West for the type of equipment manufacturing that did not require a major industrial complex. It is in this area that firms such as Westfield, Morris, and Sakundiak found profitable ground upon which to develop. It was possible to set up a manufacturing shop capable of rolling steel to make the tubes for augers and to shape and weld steel for the spiral augers. For Morris, the technology required in the manufacture rod-weeders was equally possible. In fact, most of the full-line companies did not stray into this market but rather allowed their dealerships to carry these locally made products. In terms of the farmer, repair parts were most often readily available either from the local dealership or in some cases directly from the plant in a nearby community where the implement was manufactured. The closeness between client and market also allowed the manufacturer to keep distribution costs to a minimum. Furthermore many of these small local firms were also able to capitalize on their closeness to the market when it came to R&D. It was very easy to either alter a product to suit a change in the market or research and develop a completely new one in response to market demand. - Fonction

-

A vehicle for transporting grain from a farm to a grain elevator, with an auger used to unload grain and on the farm for filling seed drills for planting. - Technique

-

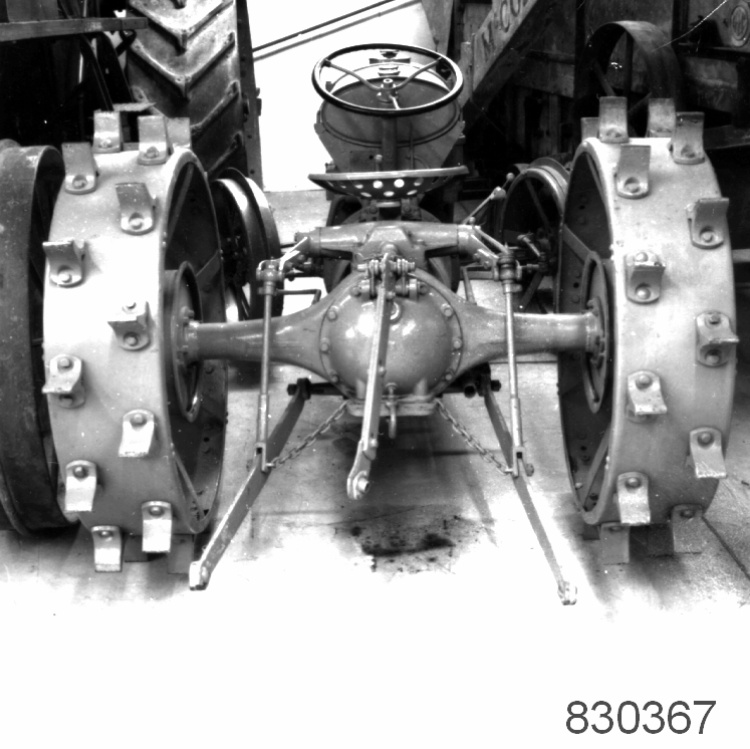

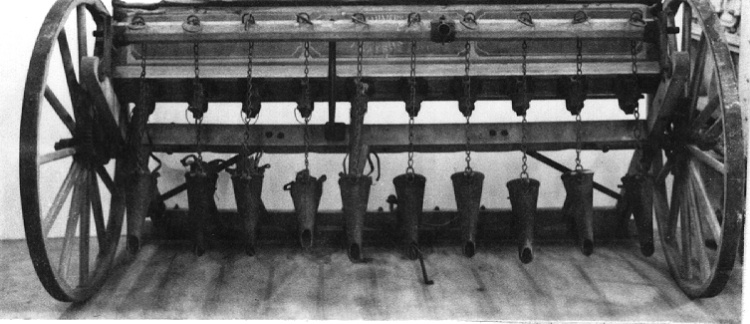

An example of a late 1960's truck with an OEM grain box and hydraulic auger mounted on it. The hauling capacity of this truck made it economically feasible for a farmer to transport grain to the elevator either directly from the field in the autumn (if it was sufficiently dry) or over the winter from an on-farm storage bin. It is equipped with a roll-tarp, this is due to concerns about moisture and grain quality as well as provincial regulations about load safety. Although unlike an open load of gravel, loose grain is not particularly dangerous, rather it is distracting to drivers forced to follow the truck. This truck has been "plumbed" with hydraulic lines that run to the back of the box, facilitating the use of a grain auger powered off the truck's system rather than from a separate gasoline engine. In terms of grain haulage technology this truck exhibits a number of very important features that can be used to represent a much wider period than its date of manufacture. With the advent of internal combustion trucks reliably capable of hauling grain, firms appeared across western Canada that were in the business of manufacturing the steel reinforced wooden boxes necessary for its haulage. The earliest generation of these truck boxes looked very much like a horse-drawn grain tank that had been transposed to a truck chassis By the 1950s, heavy duty trucks were being equipped with a hydraulic piston that could be used to raise the box to ease grain dumping. This hydraulic tipping mechanism made it simpler to unload grain into an auger for transfer into storage bins or into the box of a seed drill. Although strap steel was used to reinforce the box particularly at the corners, most of the floor, end and side panels were built of 2 inch thick dimensional lumber. This was due to the fact that steel welding and related metal forming was not particularly common in rural western Canada, and use of steel was limited to dump truck box construction. By the 1960s, IHC was offering two lines of heavy-duty trucks, the Cargostar and the Loadstar. Most commonly the former featured an IHC built enclosed box and the later was sold with a bare chassis. The gear arrangement on the Loadstar varied from the Cargostar in that it offered more lower gears with greater torque and that the truck was not outfitted with a gear suited to use on four series highway driving. Although not the rule, the engines in Loadstars were more regularly designed to run on gas rather than diesel fuel. These trucks were manufactured in IHC's Hamilton facility using components that had been produced by IHC or one of its subsidiary suppliers. Grain augers with paddles had been in production since the late 1920s. Their appearance on the market corresponded with that of wooden cylindrical grain storage bins. Although sufficient research to validate the claim has not been undertaken, Peter Pakosh of Versatile fame is often credited with inventing and perfecting the twist auger in the late 1940s when he was still employed by Massey-Harris in Toronto. When he established Versatile in Winnipeg grain augers were a standard of the company's line of smaller equipment. These devices were powered by a small gasoline engine that sat on a wheeled frame near the bottom end of the auger. They were usually built in 6, 7 and 8 inch diameters with tube lengths ranging from 20 to 40 feet. The greatest liability was the engine, which was exceptionally hard to start in the cold winter months when hauling grain. - Notes sur la région

-

Inconnu

Détails

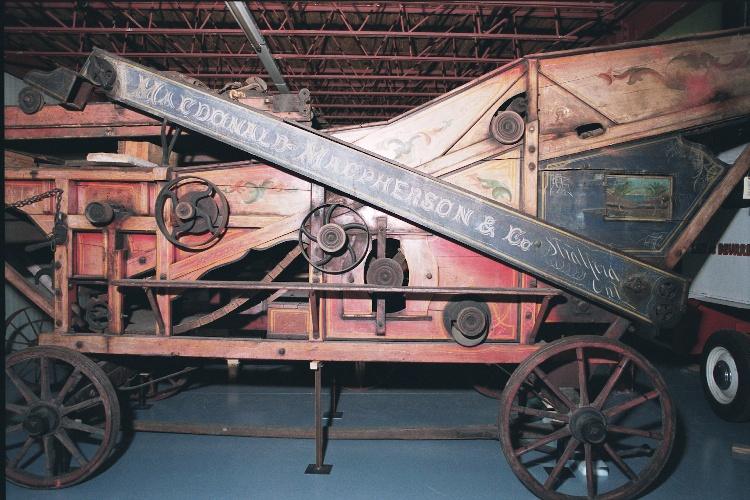

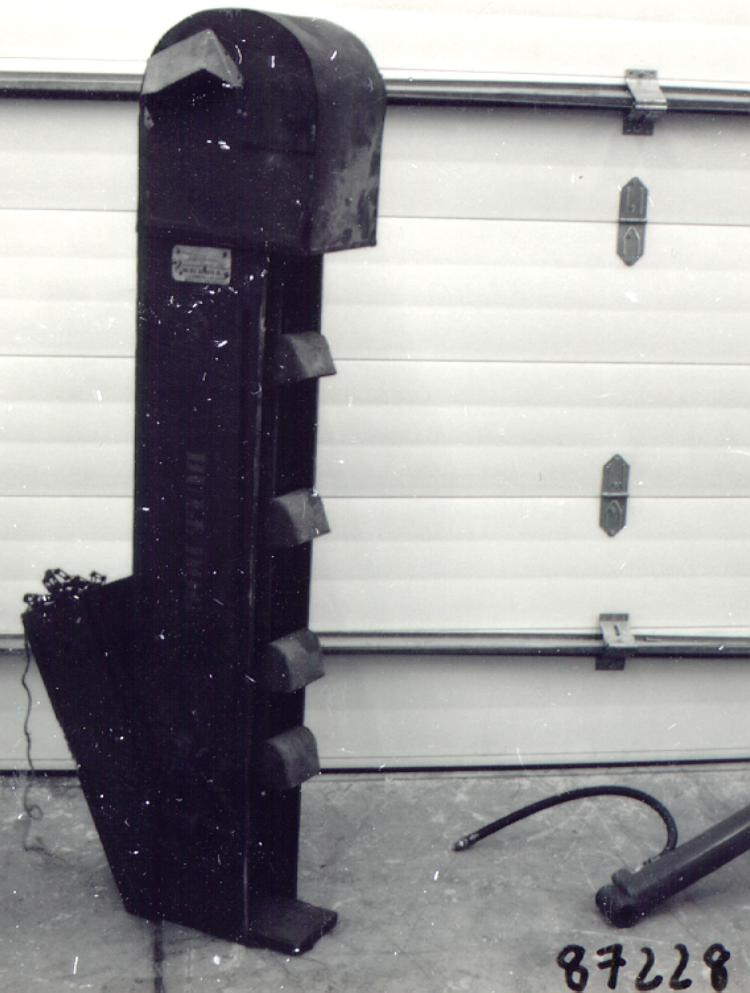

- Marques

- red and black 'IH' logo on hood front/ silver metal applique lettering on wither side of hood reads 'International [script]/ LOADSTAR/ 1600'/ yellow 'WESTAR' stenciled on auger/ manufacturer' s label on auger is unreachable/ warning labels on auger

- Manque

- S/O

- Fini

- green painted cab/ green and red painted grain box with black painted base/ black painted front grille and parts/ black steering wheel/ red and orange synthetic lamps/ colourless transparent glass/ black synthetic and plated metal controls and dials on black dashboard/ black synthetic seat covers covered multicoloured blanket covering it/ black carpet/ grey interior roof/ red painted auger/ black tires, hoses, parts

- Décoration

- yellow lining on black / 2 red painted bars along each side of grain box

FAIRE RÉFÉRENCE À CET OBJET

Si vous souhaitez publier de l’information sur cet objet de collection, veuillez indiquer ce qui suit :

International Harvester Co. of Canada Ltd., Camion, 1968, Numéro de l'artefact 2007.0002, Ingenium - Musées des sciences et de l'innovation du Canada, http://collections.ingeniumcanada.org/fr/id/2007.0002.001/

RÉTROACTION

Envoyer une question ou un commentaire sur cet artefact.

Plus comme ceci