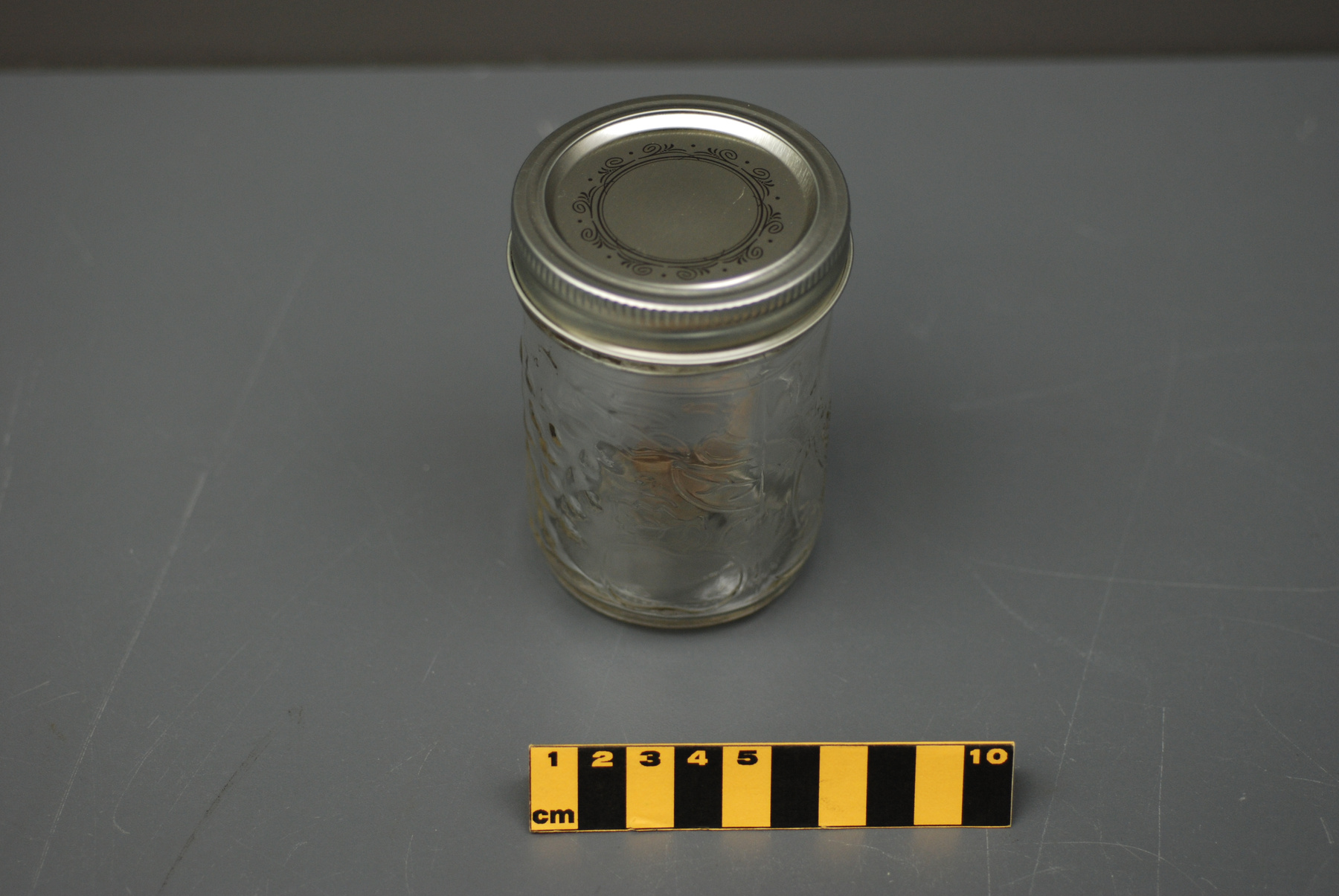

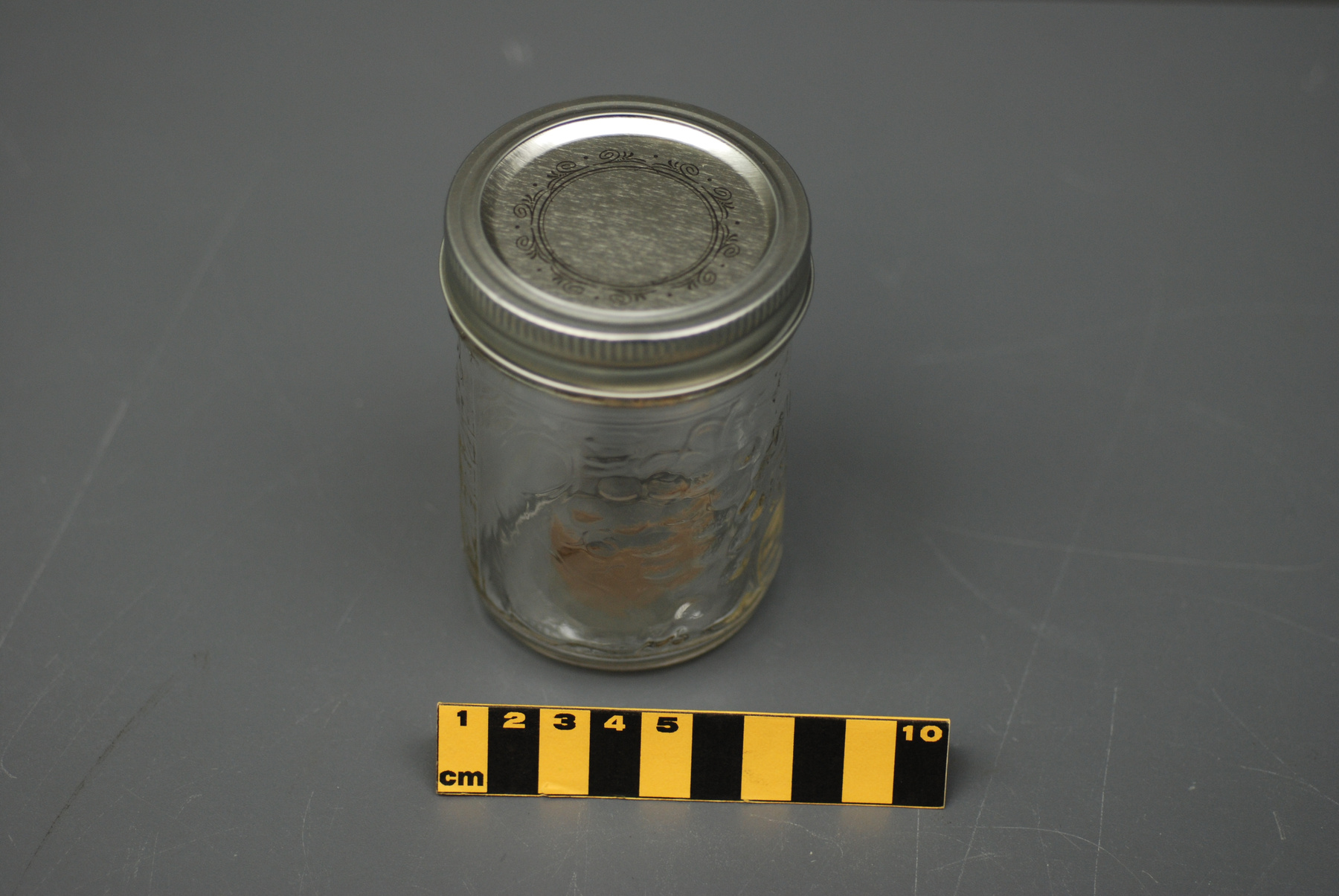

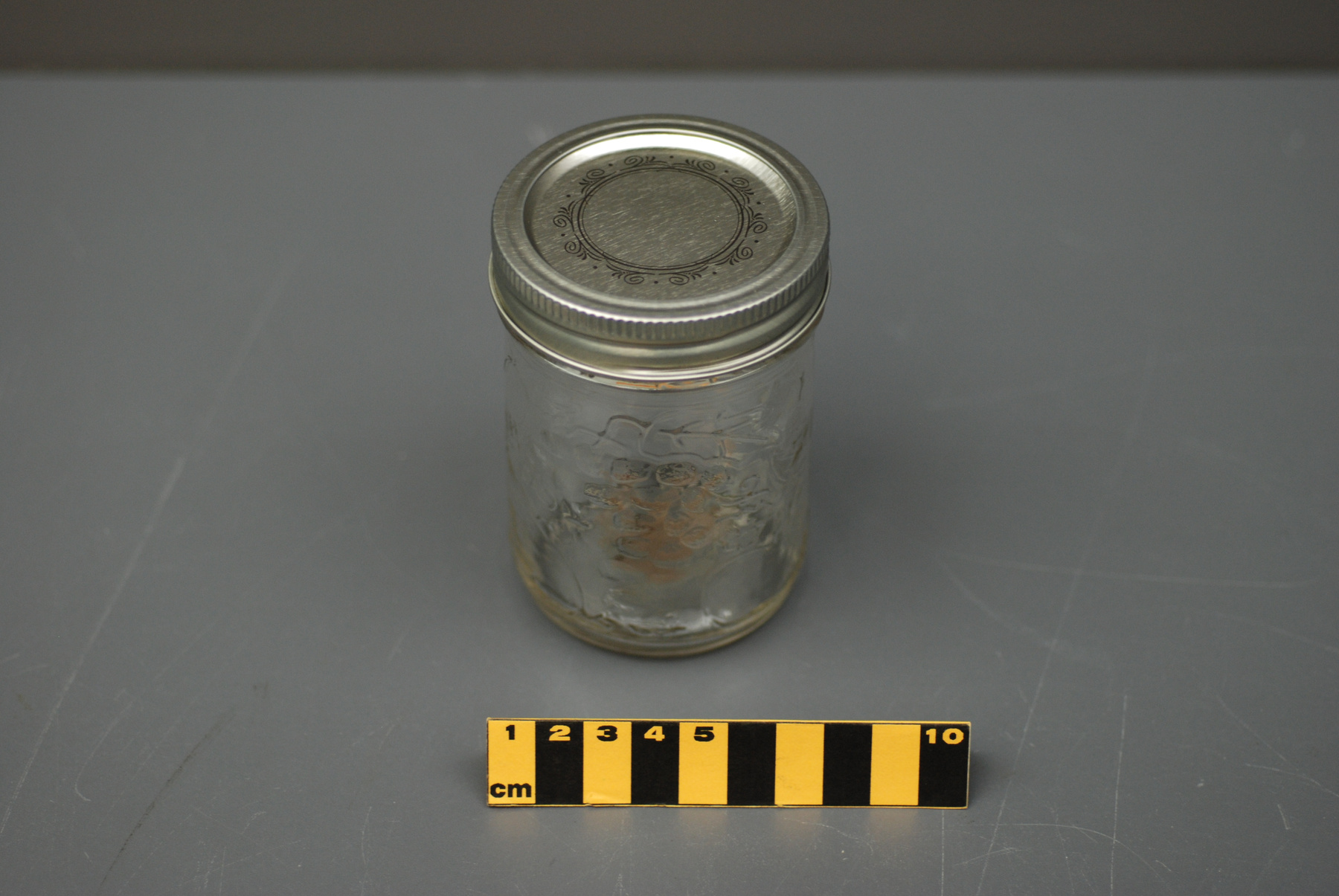

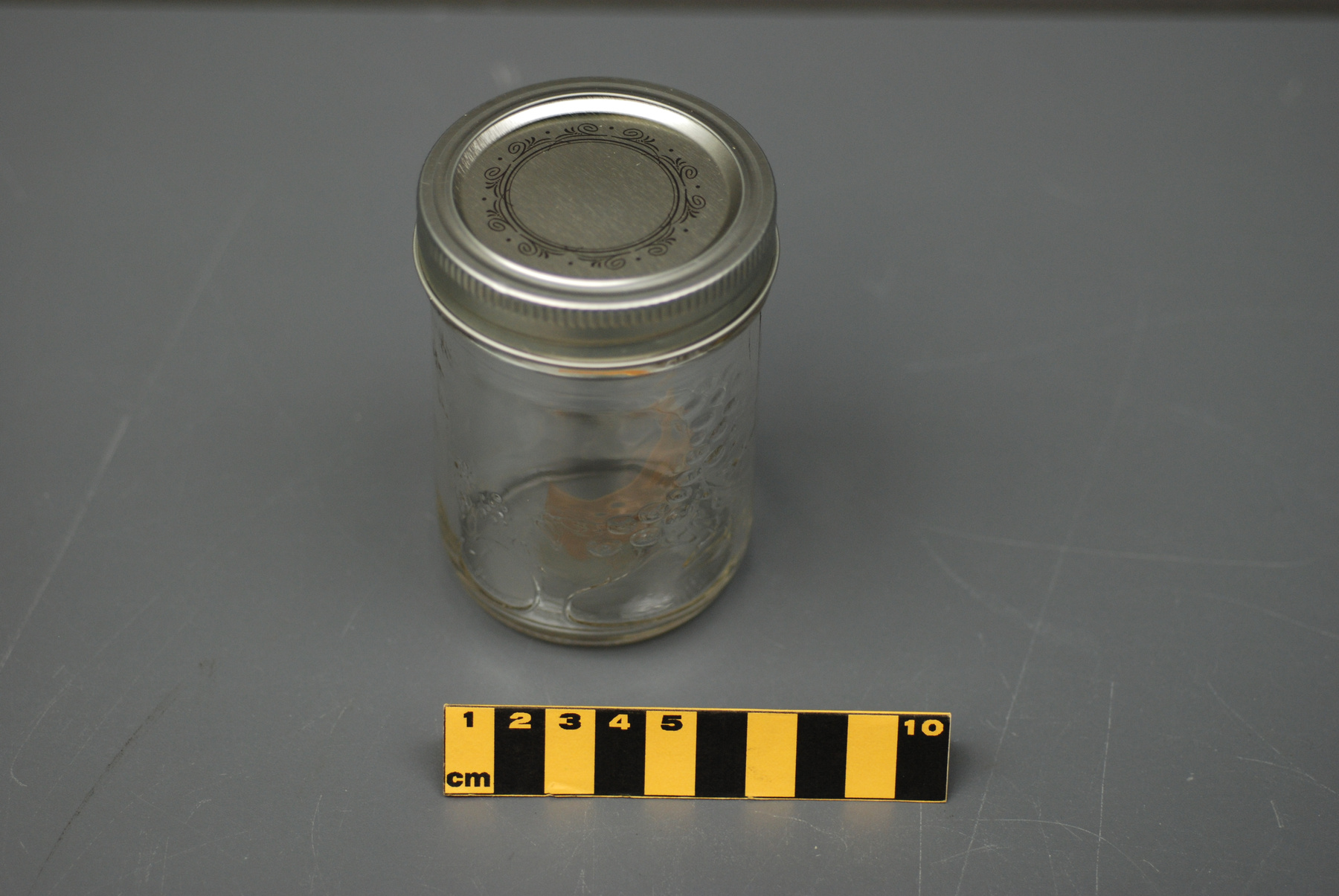

Bouilloire

Utiliser cette image

Puis-je réutiliser cette image sans autorisation? Oui

Les images sur le portail de la collection d’Ingenium ont la licence Creative Commons suivante :

Copyright Ingenium / CC BY-NC-ND (Attribution-NonCommercial 4.0 International (CC BY-NC 4.0)

ATTRIBUER CETTE IMAGE

Ingenium,

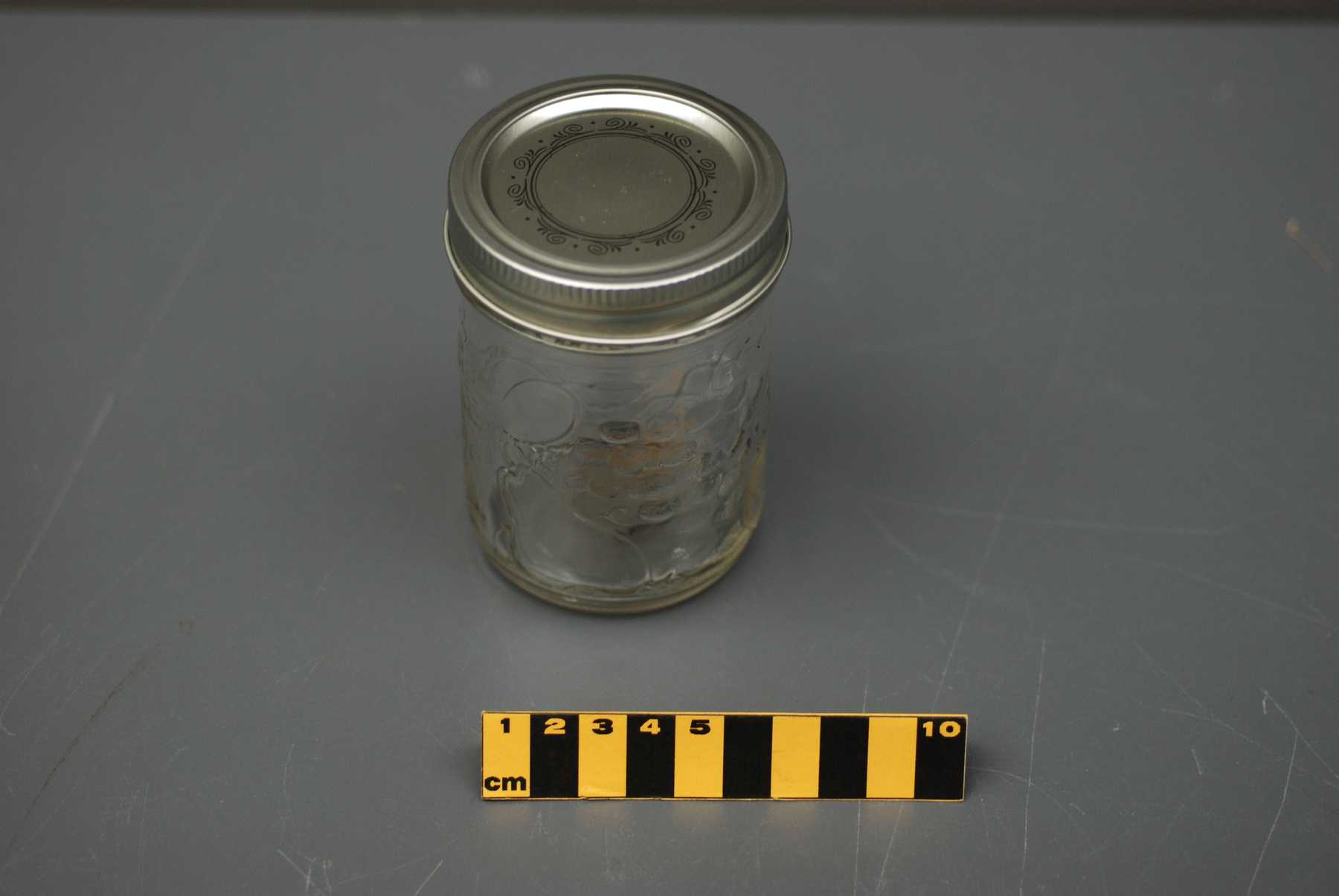

2009.0142.001

Permalien:

Ingenium diffuse cette image sous le cadre de licence Creative Commons et encourage son téléchargement et sa réutilisation à des fins non commerciales. Veuillez mentionner Ingenium et citer le numéro de l’artefact.

TÉLÉCHARGER L’IMAGEACHETER CETTE IMAGE

Cette image peut être utilisée gratuitement pour des fins non commerciales.

Pour un usage commercial, veuillez consulter nos frais de reproduction et communiquer avec nous pour acheter l’image.

- TYPE D’OBJET

- industrial/jam/steam

- DATE

- 1930

- NUMÉRO DE L’ARTEFACT

- 2009.0142.001

- FABRICANT

- Coulter Copper & Brass Co. Ltd.

- MODÈLE

- UW12C

- EMPLACEMENT

- Toronto, Ontario, Canada

Plus d’information

Renseignements généraux

- Nº de série

- 3649

- Nº de partie

- 1

- Nombre total de parties

- 1

- Ou

- S/O

- Brevets

- S/O

- Description générale

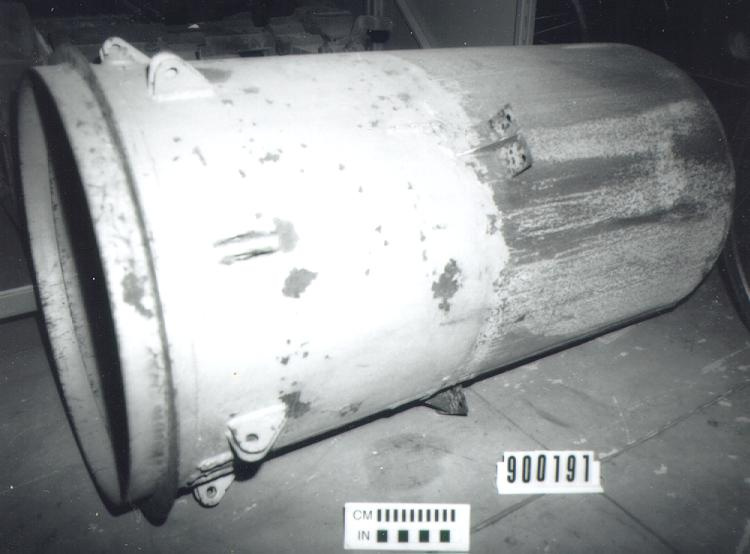

- non-ferrous metal kettle mounted on non-ferrous metal stand/ ferrous metal parts

Dimensions

Remarque : Cette information reflète la taille générale pour l’entreposage et ne représente pas nécessairement les véritables dimensions de l’objet.

- Longueur

- 101,0 cm

- Largeur

- 75,0 cm

- Hauteur

- 121,5 cm

- Épaisseur

- S/O

- Poids

- S/O

- Diamètre

- S/O

- Volume

- S/O

Lexique

- Groupe

- Agriculture

- Catégorie

- Traitement de récolte

- Sous-catégorie

- S/O

Fabricant

- Ou

- Coulter

- Pays

- Canada

- État/province

- Ontario

- Ville

- Toronto

Contexte

- Pays

- Canada

- État/province

- Ontario

- Période

- 1930s +

- Canada

-

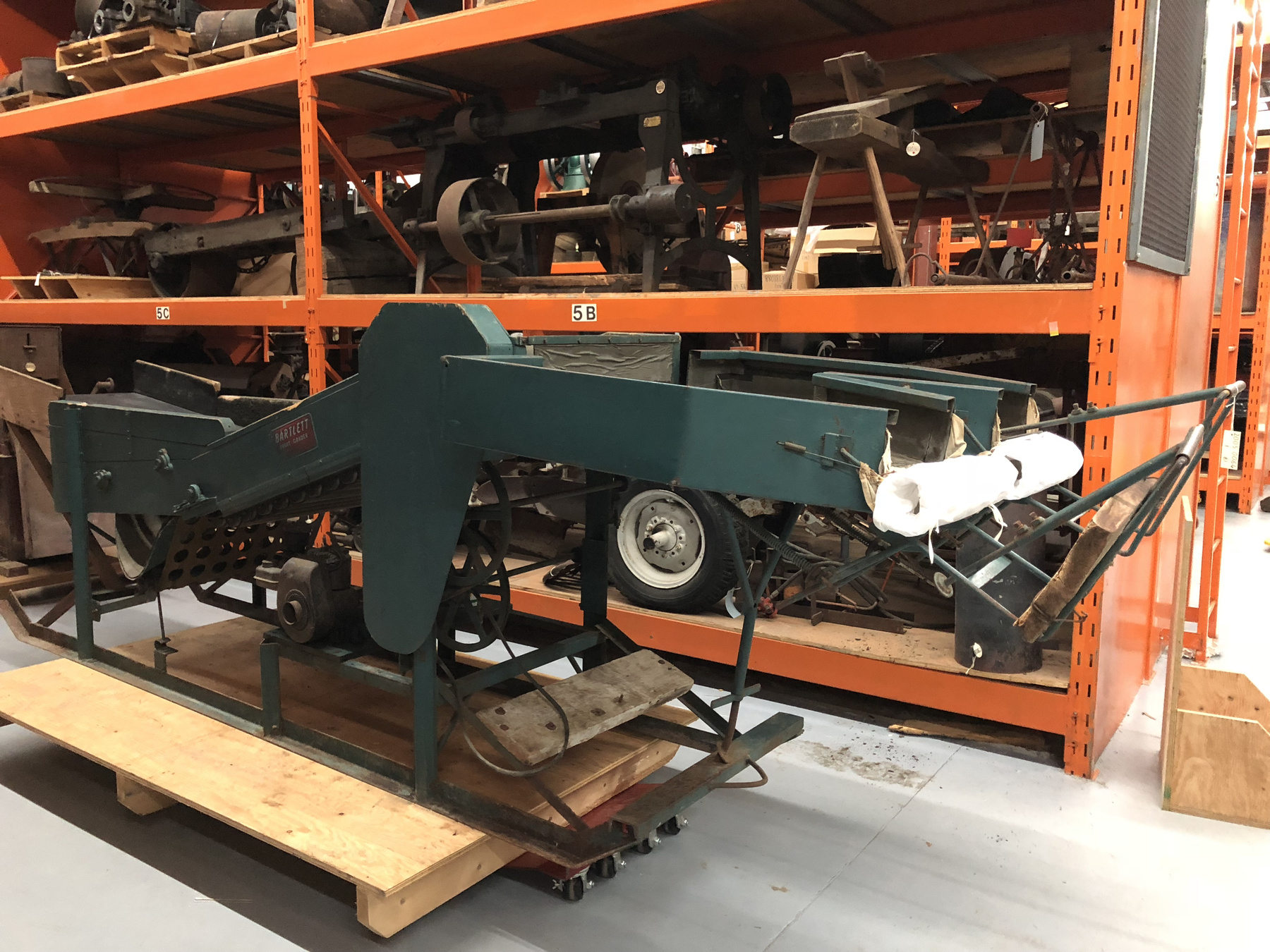

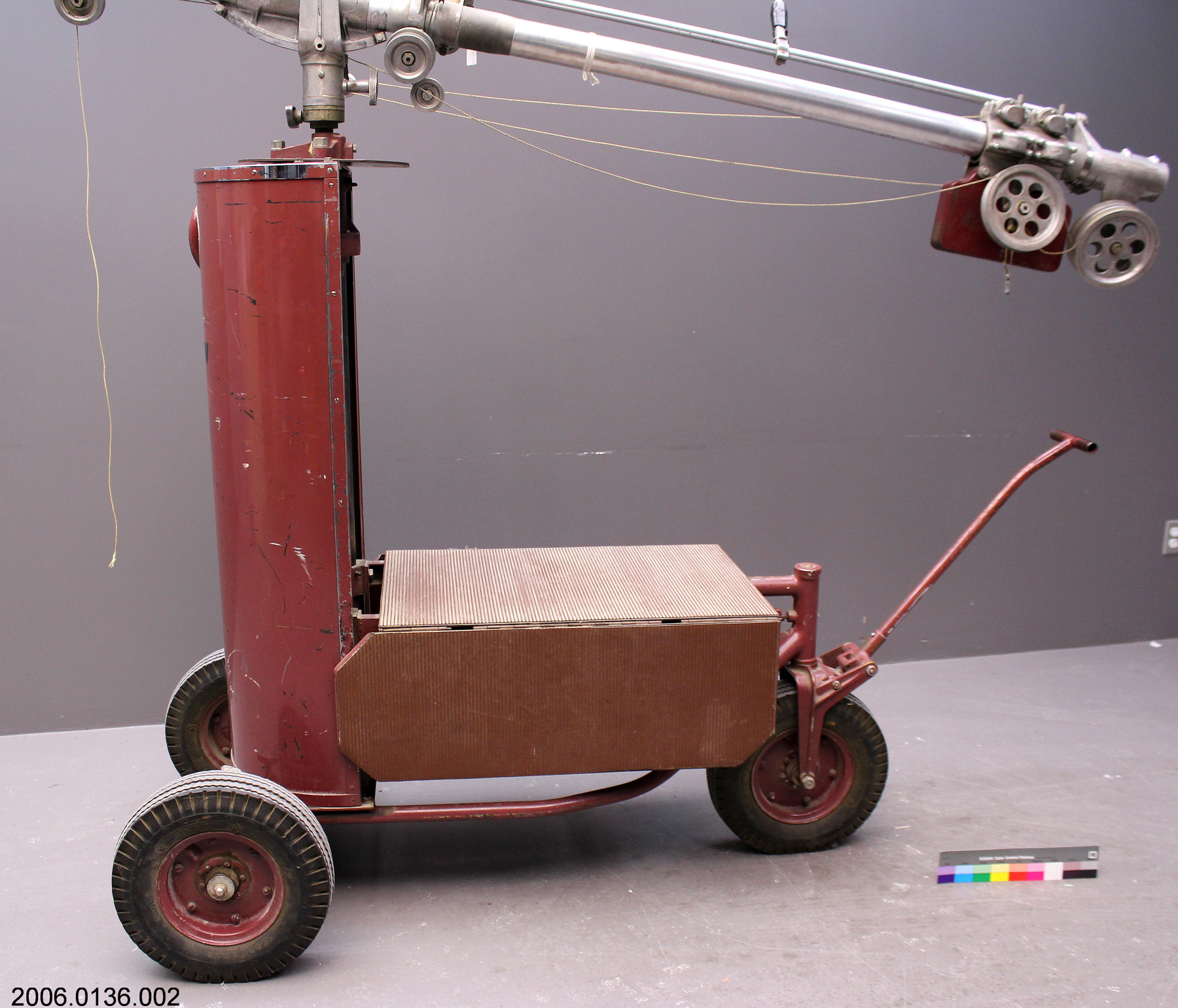

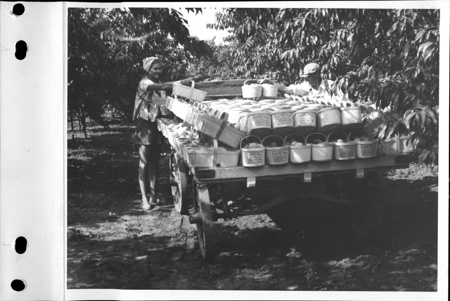

A Canadian made kettle used to make jam or jelly by the Canadian food manufacturer E.D. Smith at the in-house processing facility affiliated with the company's farms. The Smith family came to the Niagara Peninsula from the United States in the late 1700s, and like their peers became mixed farmers. Sylvester Smith, Ernest D'Isreali's father began the market garden and orchard business in the 1870s. With the growth of urban centres in the golden horseshoe of Ontario and the development of a rail network the family began shipping their crops to those centres. By the 1880s and E.D.'s time at the helm, competition from the numerous other orchardists in the Niagara region indicated that if the family enterprise were to remain viable there was a need to consider adding value to their farm products. Hence the orchard and fruit crops that might have been shipped to Toronto or Guelph by blower car in the raw form were processed in jams, jellies and eventually pie fillings and sold into that same urban market for a great deal more. Furthermore unlike the high percentage of wastage associated with the shipment and sale of a raw product, with jams and jellies the crop could be processed as it was picked and sold in a form that had a long shelf life. Initially the canning company was called E.D. Smith but with the addition of other family members its name was changed to E.D. Smith and Sons. It was and remains a wholly family owned operation. By the early 1990s the labour costs to pick the company's acres of fruit and orchard crops were felt to be too high so they went to a pick-your-own operation so a large central warehouse was constructed in which was stored baskets and picking ladders etc. In addition objects were collected from the farm and factory, text panels were produced and in 2003 a "display" was opened in half of the ground floor that it was hoped would provide some education for the folks coming to pick their own fruit. Rather than being designed to promote the E.D. Smith company, this material touted the health benefits of the pick your own crops such as strawberries and cherries and provided information on the husbandry of those crops. This new facility, the Niagara Fruit Education Centre was solely underwritten by the E.D. Smith Company. In Fall 2008 the decision was made to end the pick-your-own operation and close the educational component and rather to focus on becoming a clearing house for the distribution of fruit to food banks in the gold horseshoe. The name for this new facility is Farmshare Canada. - Fonction

-

A cooking vessel for rendering fruit into jams or jellies. - Technique

-

In the mid to late 19th century and early 20th century the canning industry was a very vital part of Canada's agricultural industry. As the nature of that industry changed, there was an increase in the size of canning operations and a significant decline in the number of firms. Whereas there had been small independent canning companies in all of Canada's fruit growing regions, now the number of firms remaining can be counted on one hand. At one time there were close to five canning operations in and near Leamington, today only Heinz remains. Like E.D. Smith many of these firms were owned by families or companies that also owned the fields and orchards in which were grown the raw materials to be canned. If this was not the instance then the canner set up production contracts with local farmers to supply them with the fruits and vegetables that they would process. By in large, even that relationship has changed. Within the last few years E.D. Smith management has mused in the agricultural press about closing its operation in Winona or at the very least importing all its fruit in a frozen state from other countries to be processed in their Ontario plant. In nearby St. Davids, Welch's decided to move it's grape juice processing plant to the United States and the last remaining independent canning company in the area also closed its doors. Unlike in domestic applications where the heat to cook the raw product was provided by a flame directly under the kettle, in the industrial application a steam jacket integrated into the bottom of the kettle provides the necessary heat. In the factory kettles were situated in rows below steam lines mounted at the ceiling. A rubber hose connected to a nipple at the line and the kettle allowed the flexibility necessary to be tipped to dump its contents into the cooling vats in front of the kettles from which the tins and jars were then filled. This jam kettle is of the second generation utilized in the factory, as the first installed c.1882 was scrapped in the late 1920s. Like most other canning operations the E.D. Smith factory had a large steam engine to power line shaft operated equipment as well as a smaller boiler unit to provide the heat to cook food products. Just as firms such as DeLaval specialized in the manufacture and sale of dairy equipment, Coulter Copper and Brass focused on the production of food production equipment such as brew kettles, stills and canning equipment. Both firms' facilities were equipped for the production of iron castings as well as to produce nickel-plated components such as cheese vats and jam kettles. It is unclear whether Coulter Brass and Copper are still in existence. - Notes sur la région

-

Inconnu

Détails

- Marques

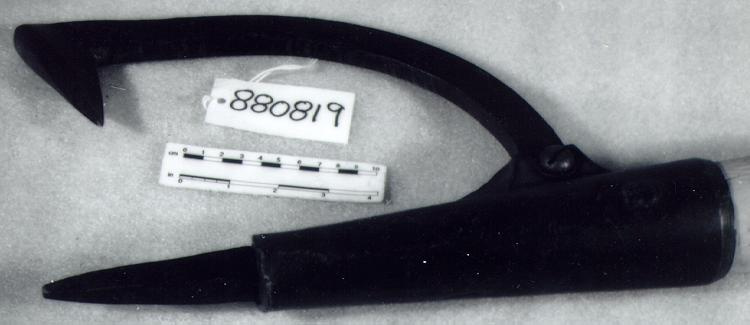

- Incised lettering on plate reads 'COULTER/ COPPER & BRASS CO. LIMITED/ SHELLS .109 HEADS .078 CRN ___/ T.S. 75000 W.P. 90 INSPECT A.R./ SERIAL NO. 3649 CODE NO. UW12C DATE 3.67'/ Plate mounted on side of stand leg reads '102 3 009'

- Manque

- Appears complete

- Fini

- Nickel? plated kettle mounted on red-brown painted stand/ metallic parts

- Décoration

- S/O

FAIRE RÉFÉRENCE À CET OBJET

Si vous souhaitez publier de l’information sur cet objet de collection, veuillez indiquer ce qui suit :

Coulter Copper & Brass Co. Ltd., Bouilloire, vers 1930, Numéro de l'artefact 2009.0142, Ingenium - Musées des sciences et de l'innovation du Canada, http://collections.ingeniumcanada.org/fr/id/2009.0142.001/

RÉTROACTION

Envoyer une question ou un commentaire sur cet artefact.

Plus comme ceci